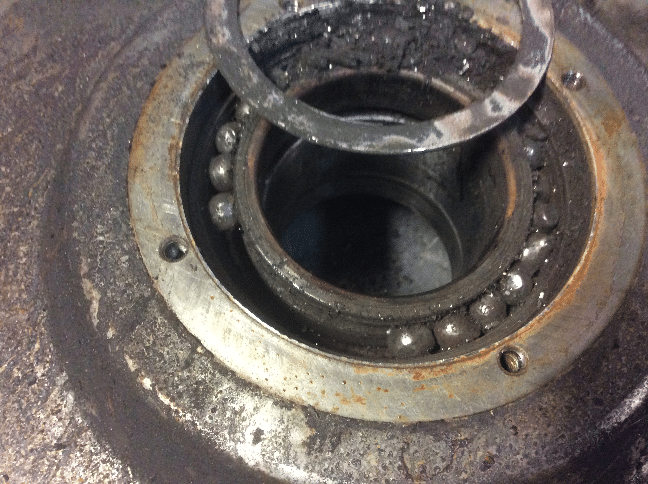

CNC Machine Tool Spindles Fail for a number of reasons. Not knowing why can cause your corporation excessive premature failures leading to unnecessary down time and loss of production. The Motor City Spindle Repair Team provides detailed “Failure Analysis Reports” to our customers to help eliminate the cause of premature spindle failures. Our documentation process includes a 4-5 page long explanation with photos that describes in great detail why your spindle failed. We list all critical surfaces on your spindle components that are worn and require to be remanufactured or replaced with oem parts.

Do you know why your spindles are failing? Would you like to receive free detailed Failure Analysis Reports?

Contact us The Motor City Spindle Repair Team and we will be happy to assist you. We can be reached at (734) 261-8600, sales@motorcityrepair.com or www.motorcityrepair.com

Emergency Spindle Repair Service

Motor City Spindle Repair has dedicated staff available 24/7 to assist you with emergency spindle repair services.

Please contact us directly at (734) 261-8600 to speak directly with our staff to answer any questions you have.

(6) Full Time Spindle Assembly Technicians available for emergency spindle repair services

In house machinists and spindle grinding services to requalify your spindle components in house

Full in house balancing and testing capabilities to test run, balance and document our spindle repair processes.

If you need immediate response to your emergency please call: (800) 716-4601.