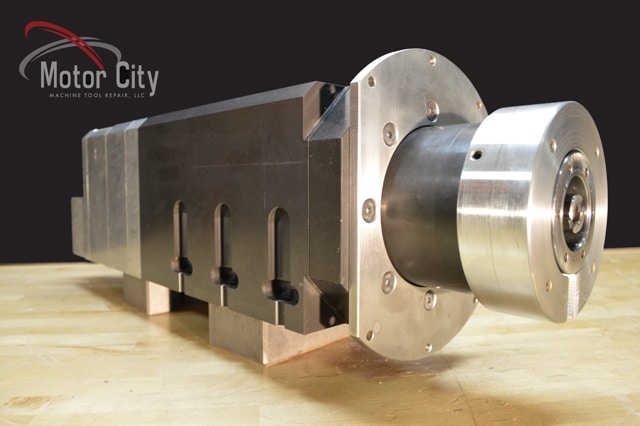

Motor City Spindle Repair received the Giordano Colombo RA Series Spindle from a customer, who had it fail on them due to bearing contamination. It is suspected that one of the seals in the spindle was worn, which allowed coolant and other debris to enter the spindle bearings, causing them to fail. The HSK 30 Tool Taper, Rear Housing Bore, and Drawbar Shaft were all worn out of specification, which we sent for Chrome and Grind work. The Colombo Spindle was motorized, so we ran several tests to make sure it was running properly, which passed. Items that were needed to replace in the Spindle were ordered, including Precision Bearings, seals and o-rings. A skilled Spindle Tech at Motor City rebuilt the Colombo Spindle. Once reassembled, the Spindle was precisely balanced and test run for four(4) hours. This was done to ensure the spindle continued to produce little to no vibrations before it was sent back to the customers. We are quite confident that this spindle will run well for a long time to come, given the proper use and maintenance.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com