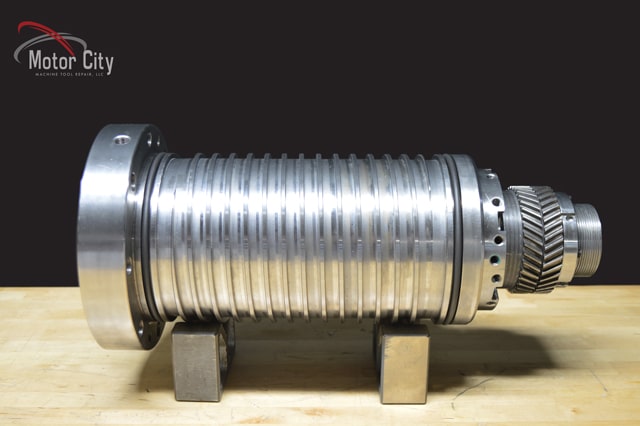

The Takami Turning Center Spindle was sent to us after the spindle was producing excessive vibrations and heat. Our Spindle Technicians quickly inspected and disassembled the spindle, revealing wear in the spindle bearings that was causing the vibrations. The Spindle parts were cleaned and new precision bearings were ordered to replace the worn ones. Seals and O-rings were also ordered to help ensure no contaminates enter the spindle in the future. Once all parts were received, one of our Skilled Spindle Technicians with an average of 20 years experience, reassembled the spindle. The Takami Lathe Spindle was then Balanced and Test Run for 4 hours at the maximum speed of 3,500 RPM. Once balanced, the Lathe Spindle was running smoothly, producing little to no vibrations or heat. The customer was very happy to receive their Takami Spindle in perfect working order, and have it running within four(4) days of sending it to us.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com