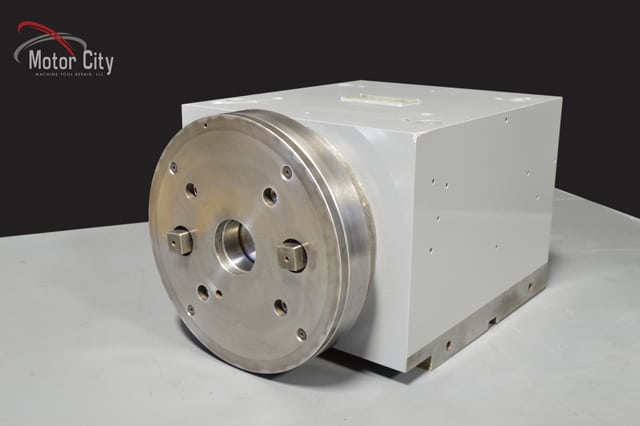

The Gros-Ite Grinding Spindle was sent to our facility, as it had failed during production. Once disassembled and inspected, our technician found that the steel ball bearings had failed, because of contamination. Upon further inspection it was found that the seals had worn and were allowing liquid to contaminate the bearings, which washed out the grease from the bearings and cause them to burn up. The seals for this machine were uncommon and needed to be custom manufactured for this job. New precision steel ball bearings were ordered for this job. Once all parts were received by us, one of our Skilled Spindle Technicians with an average of 20 years experience, reassembled the spindle. The Gros-Ite DBL-150 was balanced and test run with exacting precision. The end product is a precisely balanced spindle, that runs as if it were brand new.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com