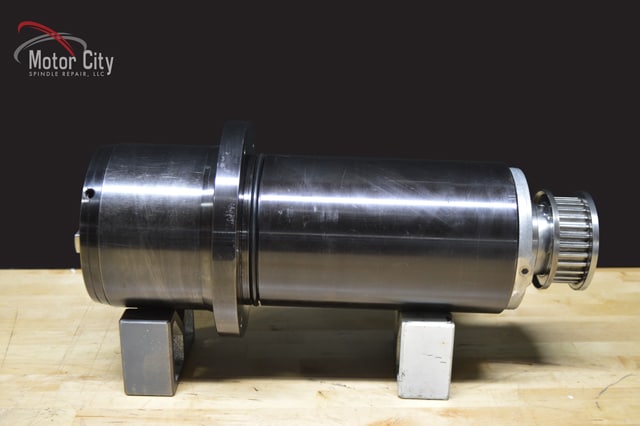

The Haas GR 150 Machining Center Spindle was sent to us with the spindle locked up. Once disassembled and inspected, it was clear that the bearings had failed and were preventing the spindle from rotating. The spindles drawbar was also missing, so we were unable to perform a pull force test of the spindles grip on a tool. There were several surfaces that had to be chrome and ground, including the ID tapper of the shaft and a bearing spacer. In addition there was a pulley plate that had to be remanufactured. After all the parts were requalified, new bearings were used to rebuild the spindle with expert skill by one of our Spindle Technicians with an average of 20 years experience rebuilding spindles. The spindle was running like new after a dynamic and static balancing of the spindle, and was test run for four hours to ensure the longevity of it’s lifespan.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com