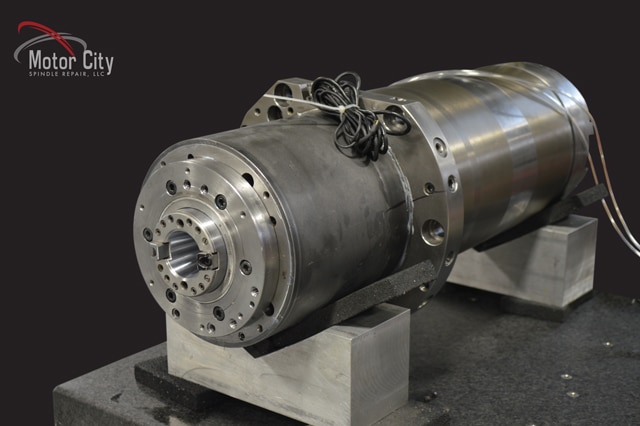

The Okuma Machining Center Spindle was received by Motor City Spindle Repair. There was much damage done to this spindle, which is indicative to a spindle crash. In addition, the flange was not seated properly, which caused coolant to contaminate the inside of the spindle. Once disassembled, the spindle parts were cleaned and the shaft was sent out for Chrome and Grind work. New drive keys and inner spacers were manufactured, to replace the damaged ones. To prevent the same coolant contamination issue from happening again, the flange was modified to allow the fitting of a Mini Maze Seal. Once the chrome and grind work was finished, one of our Skilled Spindle Technicians rebuilt the Okuma Spindle with new Precision Ceramic Ball Bearings and Steel Roller Bearings. Our Technician utilized state of the art testing equipment to balance the Okuma Vertical Machining Center Spindle, to ensure the quality of the repair and longevity of the spindles lifespan.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com