Motor City Spindle Repair specializes in repairing Speed Reducers / Gear Boxes. All speed reducers are gearboxes but not all gearboxes are speed reducers. Speed reducers are gear trains between a motor and a piece of machinery. The speed reducer reduces the rpm that is transmitted between these two end points. Speed reducers take the torque created by the motor and multiply it along with reducing the speed (the rpm output) of the input so that the output is the correct speed.

Gearbox is the gear train between a motor and a piece of machinery.

Therefore, all speed reducers are gearboxes.

However, not all gearboxes are speed reducers. Special gearboxes can be tooled to increase the speed of the input but are not common so therefore, not all gearboxes are speed reducers.

Our skilled technicians have worked on a number of different gear boxes with varied complexities.

Motor City Spindle Repair has some of the fastest lead times in the Midwest. We are able to turn around machine repair quickly, because we have skilled workers with experience.

Contact us at (734) 261-8600 for your next opportunity with Motor City Spindle Repair.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

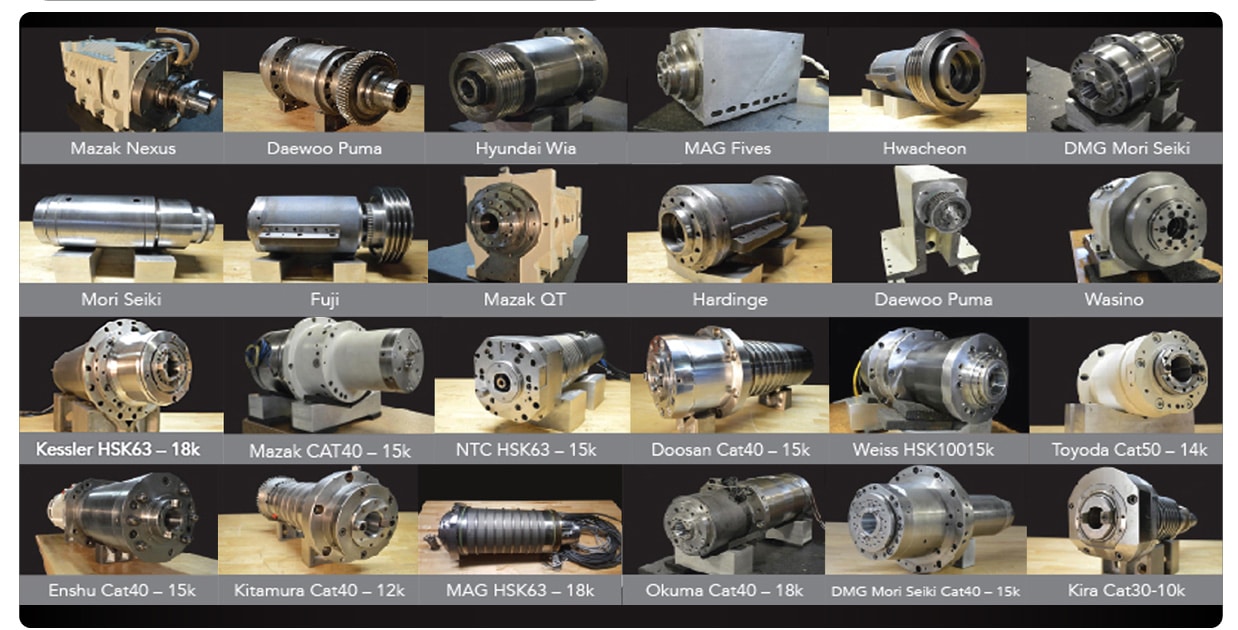

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair