Need Tips on Moving to a New Facility?

Changing facility locations can be a long, expensive, and frustrating process.

When moving your production facility from one location to another,

you will undoubtedly incur unnecessary complications

that could pile on more expenses or create delays.

Here’s some lessons learned in getting your new lean manufacturing facility up and operational.

Avoiding complications by using a clear, consistent process that is well-documented.

Below are some lessons learned to help minimize lost production time and expenses related to the move.

Step 1: Review Your Decision to Relocate

After you’ve made the choice to move your production facility to a new location, take some time to review your decision in detail.

Step 2: Communicate the Intent to Move

Your company’s relocation to a new facility should not come as a surprise to workers, clients, investors, and authorities.

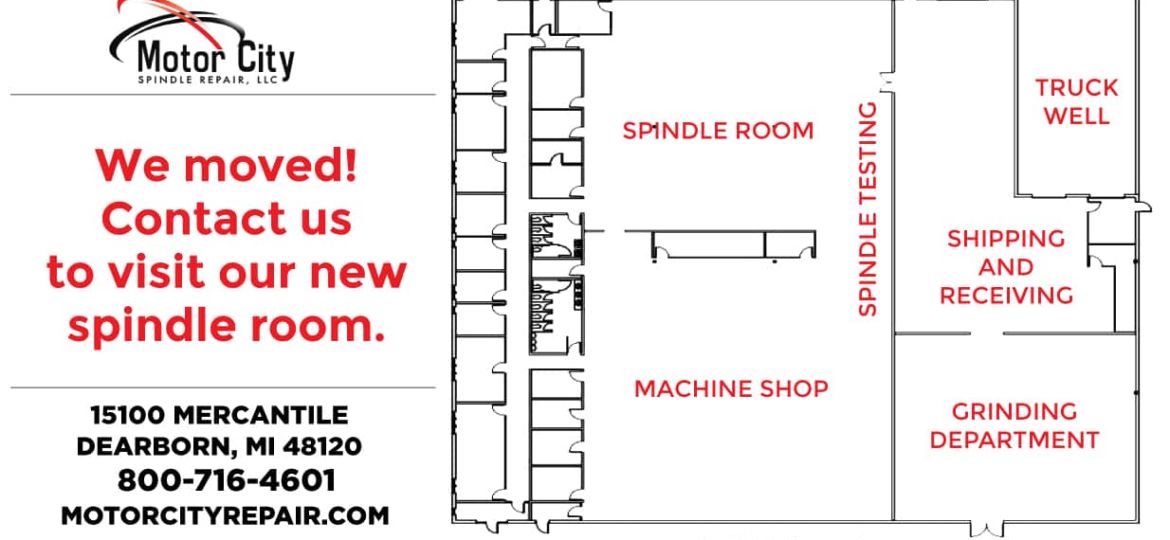

Step 3: Create a Layout for the New Facility

Having a plan in mind for the placement of your company’s equipment and workstations at the new facility well before you ever arrive there is key to a smooth transition.

Step 4: Prepare Your Company’s Documents and Records for Transfer

Make sure to take all of your company’s quality management system documents from your distribution list and prepare to reissue them at your new facility location.

Step 5: Consider Your Assets

Any customer property that you have in your possession should be thoroughly inventoried and tracked during the moving process so that the risk of customer materials, parts, tooling, etc. that could be lost is minimized. This includes a condition check of the customer property before and after the move to verify that no damage was done during the move. Your own company’s property should be inspected and tracked in a similar fashion.

Step 6: Preserve Products during Transit

When moving facility locations, your company should do everything it can to preserve the current condition of any products being moved.

Step 7: Handle Calibrated Equipment with Special Care

If you have equipment that needs to be calibrated, that equipment needs to be packed and transported in a way that keeps that equipment within its operational tolerance.

Step 8: Test Your Equipment after the Move

Every production machine that you move from the old facility to the new one should have a test piece made on it.

Step 9: Perform an Internal Audit

Now that your new facility is up and running, you should run an internal audit to make sure that your production process is running smoothly.

Step 10: More Communication

Upon completing your move and making sure your new facility is fully operational, it’s time to send out another communication to your customers and the regulatory bodies your company has to report to.

Step 11: Final Review

Conduct one last review of your company’s move to discuss the moving process and the results of your internal audit.

Contact us to visit our new spindle room.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

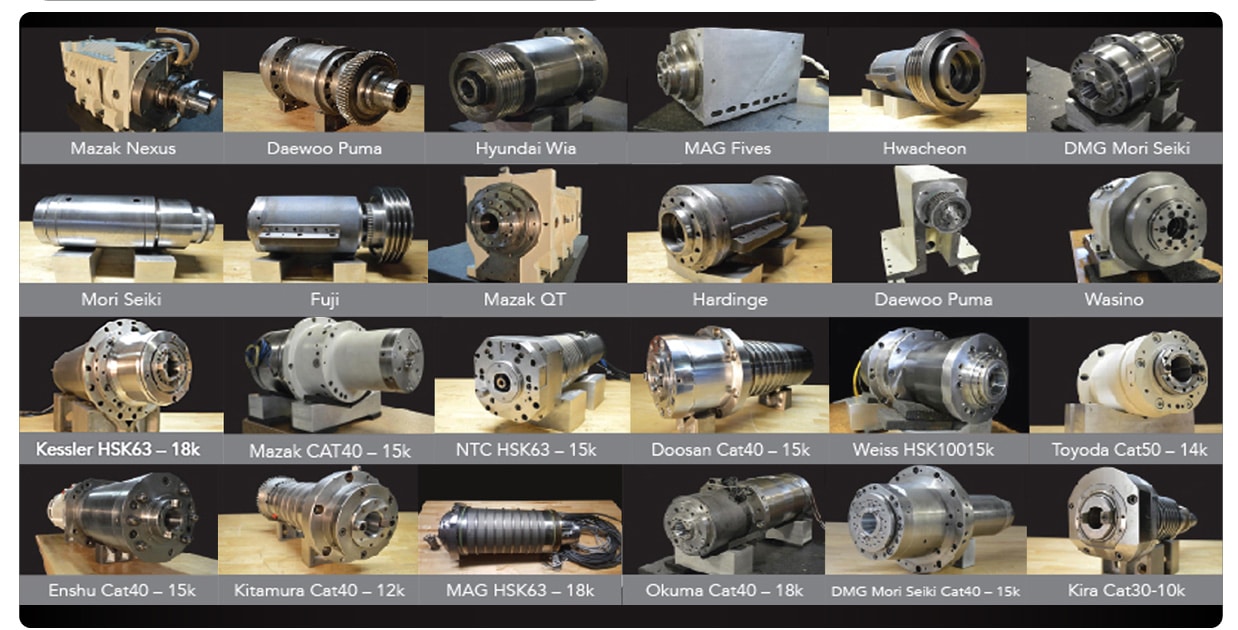

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NSK Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair