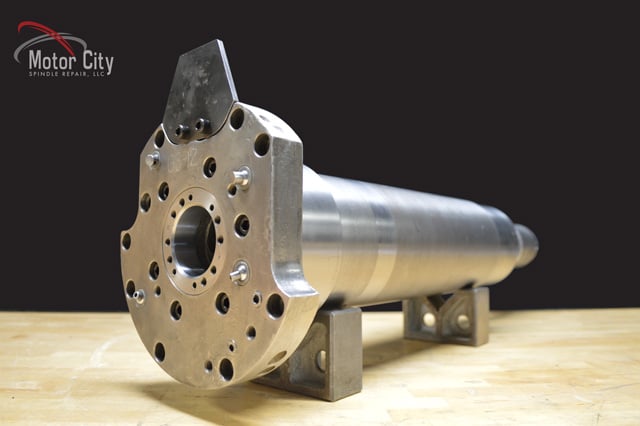

A Toyoda TH Series Spindle was received at our repair facility, already disassembled from another repair shop that had quoted to high and with a much longer lead time than ours. We quickly inspected & quoted the repair to our customer that day. There was much wear and tear on this spindle, because of which many surfaces of the spindle needed Chrome and Grind work done to it, including: the Front Bearing Journal, the Pilot ID, and the Front Housing Bore. Both the Drawbar Pin and an Inner Spacer were damaged, and were remanufactured to factory specifications. New High Speed Roller Bearings and Angular Contact Bearings replaced the old bearings that had excessive wear and tear. Once rebuilt, the spindle was test run & balanced with exacting precision by one of our Skilled Spindle Technicians.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com