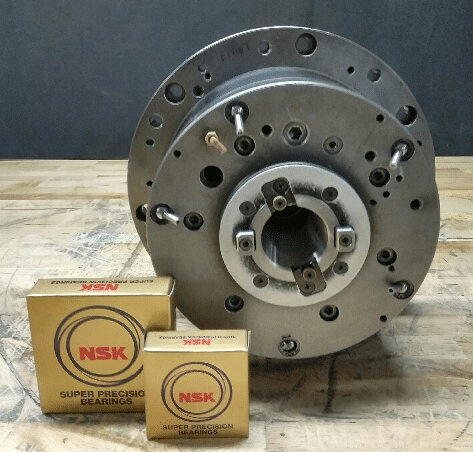

This Toyosk Spindle was received by Motor City. After disassembly and inspection, our Spindle Technician concluded that the THMC 311 spindle failed due to it crashing during production. The crash caused damage to the HSK 40 tool gap, the Gripper Set, Bearings and Spacers. The Shaft and Bearing Spacers were sent out for Chrome and Grind work, to requalify them back to factory specification. Items such as Bearings, Gripper Set, O-rings, and Disc Springs were ordered to replace the damaged ones. Following the reception of all parts for this spindle, one of our Expert Spindle Technicians (with an average of 20 years experience) rebuilt this Toyosk Spindle. One of the most key parts of the rebuild is to properly balance and test run the spindle, making sure to break in the bearings. The Spindle was carefully balanced and ran up to the maximum speed of 10,000 RPM. The result of this tedious procedure, is a spindle that runs like new for a long time.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com