CNC Spindles are becoming faster and faster every year and pushed to their limits by OEM spindle manufacturers and CNC machine tool designers. Machine Tools are sold to end-users with expectations to decrease cycle times and increase profits. This commonly occurs, allowing CNC machining companies to enjoy the dividends. However, those of us living in the CNC machine tool industry understand that not everything goes as expected and nothing stops profits like a CNC machine tool with a locked-up spindle.

To answer these questions it is critical to understand the very basics of cnc spindle bearings.

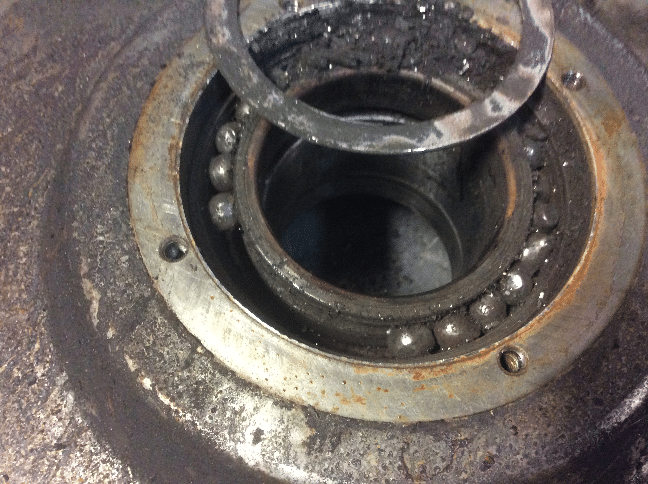

Let’s start with the most commonly found bearings used in the front-end of machining center spindles:

Angular Contact Bearings.

Angular contact ball bearings found in CNC spindles are bearings where the inner- and sometimes outer-races are relieved. They allow the axial load carrying capacity to be increased for higher metal removal rates with extended spindle life by achieving higher operational speeds (rpm) and better endurance.

TOP 3 REASONS SPINDLES FAIL:

If your spindles are failing due to reasons #1 & #2 above then upgrading your spindles will be of no value. The solution to those causes of premature spindle failure is completely different and must be tackled with an entirely different approach.*

However, if your CNC spindles are failing to due reason #3, then looking at the overall design of your spindle and specifically its type of spindle bearing and bearing configuration can significantly increase your spindle life and help eliminate costly premature spindle failures.

WHY DO YOUR SPINDLES FAIL?

The best advice we can offer you is to investigate why your spindles fail:

Ask around the industry of other end users who run identical make and model machine tools that you own. Don’t trust only one source. You may not get the most accurate answer from those that sold you your machine tool or designed your spindle.

Do not guess. Contact an expert and get actual documentation. Ask for proof via Failure Analysis Reports with digital photographs and video of your actual spindle.

Does your spindle supplier offer upgrades to your spindle design? We do. In many cases our team at Motor City Spindle Repair can help to extend the life of your machine tool spindles.

ASK AN EXPERT:

If you are interested in speaking with us at Motor City Spindle Repair we’d love to hear from you to schedule a free consultation.

Email us at sales@motorcityrepair.com or call us at (734) 261-8600.

Motor City Spindle Repair offers “Spindle Crash Detection” along with “Continuous Spindle Monitoring Vibration Analysis” and various upgrades to eliminate different forms of Spindle Contamination from chip ingression and coolant ingression, known causes of spindle bearings and spindle motor windings failure.