Choosing the Right Spindle for Your CNC Machine: A Comprehensive Guide

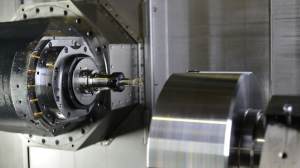

When setting up or upgrading your CNC machine, one of the most crucial decisions you’ll make is selecting the right spindle. The spindle is the heart of any CNC system, as it controls the cutting process and determines the quality, speed, and efficiency of your work. With a wide range of spindles available, it’s essential to understand the factors that affect performance and ensure you pick the best one for your specific needs.

In this blog, we’ll break down what you need to know about CNC spindles, the different types, and key factors to consider when making your choice.

What is a CNC Spindle?

A CNC spindle is a rotating component that holds and drives the cutting tool. It powers the movement of the tool that interacts with the material being cut, milled, or drilled. The spindle is typically powered by an electric motor and is equipped with high-speed bearings that allow for smooth rotation.

Spindles are available in various sizes, speeds, and power ratings, depending on the kind of work you want to perform. They come in two main types: air-cooled and water-cooled. Each type offers its benefits and limitations, making it essential to understand the differences before making your decision.

Types of CNC Spindles

- Air-Cooled Spindles

Air-cooled spindles are commonly used in smaller, less demanding operations. They rely on air flow to cool the motor and bearings, making them lightweight and easy to maintain. Air-cooled spindles are typically less expensive than their water-cooled counterparts and are often used in hobbyist or entry-level CNC machines.Pros:- Lower cost

- Less maintenance

- Easier to install (no need for coolant systems)

Cons:

- Less efficient cooling at higher speeds

- Louder operation

- May overheat during prolonged use

- Water-Cooled Spindles

Water-cooled spindles are used in more advanced CNC machines that require higher speeds and precision. These spindles are equipped with a water-based cooling system that keeps the motor and bearings at an optimal temperature, even during extended operation. As a result, water-cooled spindles can handle larger workloads and provide higher torque.Pros:- Better cooling, allowing for higher speeds and more power

- Quieter operation

- Suitable for demanding industrial applications

Cons:

- More expensive

- Requires a cooling system, adding to maintenance needs

- Larger and heavier

Factors to Consider When Choosing a CNC Spindle

- Power Requirements (Motor Power and Torque)

The power of the spindle is crucial to the success of your CNC operations. A more powerful spindle provides higher torque, allowing you to cut through harder materials more efficiently. Consider the materials you’ll be working with and the complexity of your projects.- For softer materials like plastic and wood, a lower-powered spindle might suffice (1-2 kW).

- For harder materials like metals, a higher-powered spindle (3-5 kW) may be necessary to handle the load and provide consistent performance.

- Spindle Speed

CNC spindles come with different speed ratings, measured in revolutions per minute (RPM). The spindle speed affects the quality of the cut, tool life, and overall efficiency of the operation.- Lower speeds are often ideal for tougher materials (e.g., metal) to avoid tool wear and overheating.

- Higher speeds are useful for softer materials (e.g., wood or plastic) where you want a smooth finish and faster cutting.

Be sure to choose a spindle that allows you to adjust speeds based on the materials and tooling you’ll use.

- Tool Compatibility

Consider the types of tools you’ll be using with the spindle. There are different types of tool holders and collets, which must be compatible with your spindle. Most CNC spindles use ER collets, but you may also encounter HSK or ISO tool holders. Make sure the spindle you choose can accommodate the types of tooling you intend to use. - Precision and Stability

A spindle’s accuracy is essential, particularly for high-precision applications like aerospace or medical machining. Look for spindles with high-precision bearings and minimal runout. The stability of the spindle is also important, especially when operating at high speeds. Poor stability can lead to vibrations that negatively impact the quality of your finished product. - Cooling System

As previously mentioned, cooling is vital for preventing overheating, particularly at high speeds. Water-cooled spindles offer superior cooling performance, making them ideal for high-demand tasks. However, air-cooled spindles can still perform well in less intensive applications and have the benefit of easier installation and less maintenance. - Size and Mounting Options

Make sure the spindle fits within your CNC machine’s design. Larger spindles may require custom mounting systems, so check that your machine has the space and capability to support the spindle’s size. The most common spindle mounting types are BT, ISO, and HSK, each designed for different applications and tooling setups. - Budget and Cost of Ownership

Your budget plays a significant role in determining which spindle to choose. Higher-power, water-cooled spindles tend to be more expensive and require additional maintenance, but they offer better performance for heavy-duty tasks. Air-cooled spindles, while less expensive, may not be sufficient for high-speed or high-power tasks.Consider not only the initial cost but also ongoing operating and maintenance costs. If you’re looking to minimize long-term expenses, air-cooled spindles may be a more budget-friendly option.

Conclusion

Choosing the right spindle for your CNC machine ultimately depends on the type of work you plan to perform and the materials you’ll be working with. It’s crucial to weigh factors like power, speed, cooling system, and tool compatibility to make an informed decision. While a more powerful and precise spindle may cost more upfront, it can save time and provide better results in the long run.

Whether you opt for an air-cooled or water-cooled spindle, the key is to match the spindle’s capabilities with the demands of your projects. With the right spindle, you can achieve higher precision, improved efficiency, and ultimately better results in your CNC machining endeavors.

If you’re in the market for a new CNC spindle, do your research and consider the factors discussed here to ensure you make the best choice for your machine and your needs.

CONTACT US ANYTIME IF YOU’D LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

*All quotes are accompanied by a detailed failure analysis report

*We frequently repair spindles in 2-5 business days in emergency situations

*Normal time averages 1-3 weeks for standard repairs

*We keep precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts in stock and on hand

*Always available 24 hours a day and 7 days a week for emergency repair service

*We deliver the repaired product to you

*Our repairs are balanced, test ran, and certified with a full 1 Year Warranty

*We repair or build new depending on your needs

*Guaranteed cost savings

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE Have questions about ballscrews? Check out our BALL SCREW WEBSITE