CNC Machines: Built to Last or Destined to Fail?

Firing up a CNC machine is a bet on its precision, power, and reliability. But have you ever wondered if it’s built to last—or designed with a hidden expiration date? In an age of disposable tech, are these machines engineered for decades of service, or designed to fail?

CNC machines are the backbone of modern manufacturing—capital investments expected to last years and deliver consistent returns. The good news? Most are built with longevity in mind. Let’s dive into what makes a machine durable and how to ensure your next purchase is a reliable workhorse.

The Core of a Durable Machine

Why do some CNC machines run for twenty years while others become a maintenance nightmare? It comes down to engineering. Reputable manufacturers design machines not just as tools but as uptime investments. Key factors include:

A Solid Foundation: Cast Iron Frames

CNC machines handle extreme vibrations, especially when cutting tough materials. That’s why the best machines use single-piece cast iron frames, which absorb vibrations and preserve precision. While welded steel frames have their place, cast iron is the gold standard for durability and long-term performance.

Precision Components: Motion Systems

Consistent accuracy depends on the motion system—ball screws, linear guides, and bearings. High-quality machines use oversized, premium components designed to handle heavy loads for millions of cycles. These ensure smooth, precise movement year after year.

The Spindle: Built for Endurance

The spindle, taking the brunt of the work, needs exceptional design. Top-tier spindles feature hybrid ceramic bearings and advanced cooling systems to

withstand heat, high-speed rotations, and heavy loads. Durability here is about staying cool and stable under stress.

Maintenance is Key to Longevity

Even the toughest machine requires proper upkeep. Longevity is a partnership between manufacturer and operator.

- Daily Maintenance: Wipe down ways, check coolant and lubrication levels, and clear chips.

- Weekly Checks: Inspect filters, grease fittings, and listen for unusual sounds or vibrations.

- Deep Inspections: Monthly and annual checks, including alignment and wear assessments, can catch small issues before they become costly failures.

A well-maintained machine holds tighter tolerances, reduces downtime, and maximizes profitability over its lifespan.

Planned Obsolescence or Technological Limits?

In industrial machinery, planned obsolescence is rare. Brands like Mazak, Haas, Okuma, and DMG Mori are known for machines that last decades. The real issue isn’t durability—it’s outdated technology. A 25-year-old machine may still run perfectly but lack the speed and features of modern controls. Fortunately, retrofitting new controls onto older machines can breathe new life into them, combining old-school strength with modern precision.

Choosing a Machine That Lasts

Ready to invest in a machine built for the long haul? Follow these tips:

- Inspect the Build: Ask about the frame material, motion components, and engineering details. Cast iron frames and high-grade motion systems are signs of quality.

- Assess Support: Ensure replacement parts and service are readily available. A reliable support network minimizes downtime.

- Plan for Growth: Buy a machine that fits not just your current needs but future demands. Overinvesting slightly now can save you from an upgrade later.

- Ask for References: Speak with other shops using the same model. Their feedback on performance, reliability, and service is invaluable.

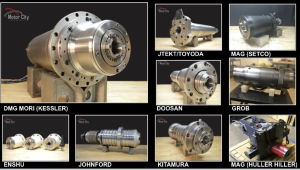

Top CNC Machine Brands

These industry leaders are trusted worldwide for their durability, performance, and innovation:

- Mazak: Known for versatility and cutting-edge tech, ideal for shops needing reliability and innovation.

- Haas Automation: Affordable, user-friendly, with unmatched service and widespread use.

- DMG Mori: Precision engineering with a focus on high performance and digital manufacturing.

- Okuma: Built for durability and thermal stability, with industry-leading controls.

- Fanuc: Famous for controls and fast, reliable machines, especially in high-volume automation.

Why Trust Motor City Spindle Repair?

When your CNC machine’s uptime and accuracy matter most, having an expert team in your corner makes all the difference. Motor City Spindle Repair specializes in diagnosing and repairing CNC spindles quickly and reliably, ensuring minimal downtime for your operation. Our experienced technicians use advanced diagnostic tools to pinpoint issues fast, and every repair is backed by rigorous testing to restore your machine’s spindle to peak performance. Whether you’re running high-volume production or tackling complex, precision work, Motor City Spindle Repair’s commitment to quality and customer service helps keep your shop running smoothly and efficiently.

Final Thoughts: Investing in Longevity

CNC machines blend strength and precision, built by engineers who understand reliability’s importance. By choosing a well-engineered machine, maintaining it properly, and using it within its design limits, you can ensure it lasts for decades. The goal isn’t to find a machine that never needs service—it’s to invest in one built for maintenance, repair, and long-term success.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US ATSALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE