It is a fact that they are not. They are someone else’s rebuilt spindle that another end user broke and sent in for repair. Often OEMs are up front with this fact. Sometimes it would appear they are blatantly misleading based on the confusion or misinformed information we hear from end users all over North America.

Broken spindles that are remanufactured correctly have all new components that are critical to function, performance and life of the spindle. Also, if critical surfaces such as spindle tapers, shaft bearing journals, housing bores or motor windings need rework a unit that is shipped in for a “spindle repair” is typically better than a “new spindle” if the spindle rebuilder knows how to properly remanufacture a spindle for optimal performance. Examples of this are a process to spindle tapers and bearing jounrals using “GPG”. GPG is a common phrase used in the spindle repair world that stands for Grind Plate Grind. This is process by which a spindle shaft is uncut often referred to as a “green grind” to remove high spots on the ID/OD of the spindle shaft and remove additional material to prep the surface for Hard Chrome. The spindle surface is then send out for Hard Chroming as nearly everyone in the spindle business does not perform the chroming process internally due to EPA restrictions. After the hard chroming process is completed the spindle shaft is then ready for a finish grind. Serious spindle repair companies have their own in house spindle grinding machine tools for speed, accurate and control of this entire process.

Hard Chroming surfaces are much more wear resistant than original materials used when manufacturing new spindle shafts so these remanufactured spindles last much longer. These surfaces have a significantly harder rockwell rating and do not damage tool holders or spindle bearings. The such but different upgrades can be done with spindle motors are contaminated or burn up for various reasons. Upgrades to these OEM spindles can be done quickly and economically that extend spindle life that are cost efficient and performed in hours or days.

When you have a down machine think about these following factors:

- WHY DID MY SPINDLE FAIL?

- HOW OFTEN DO I HAVE MY SPINDLES REBUILT?

- SHOULD I “EAT THE CORE”? WHAT IS “EATING THE CORE”?

- IS THE OEM REALLY MY BEST OPTION or HAVE I NOT FOUND A REAL SPINDLE EXPERT YET?

Consider these factors and reach out to the spindle repair experts for free advice.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

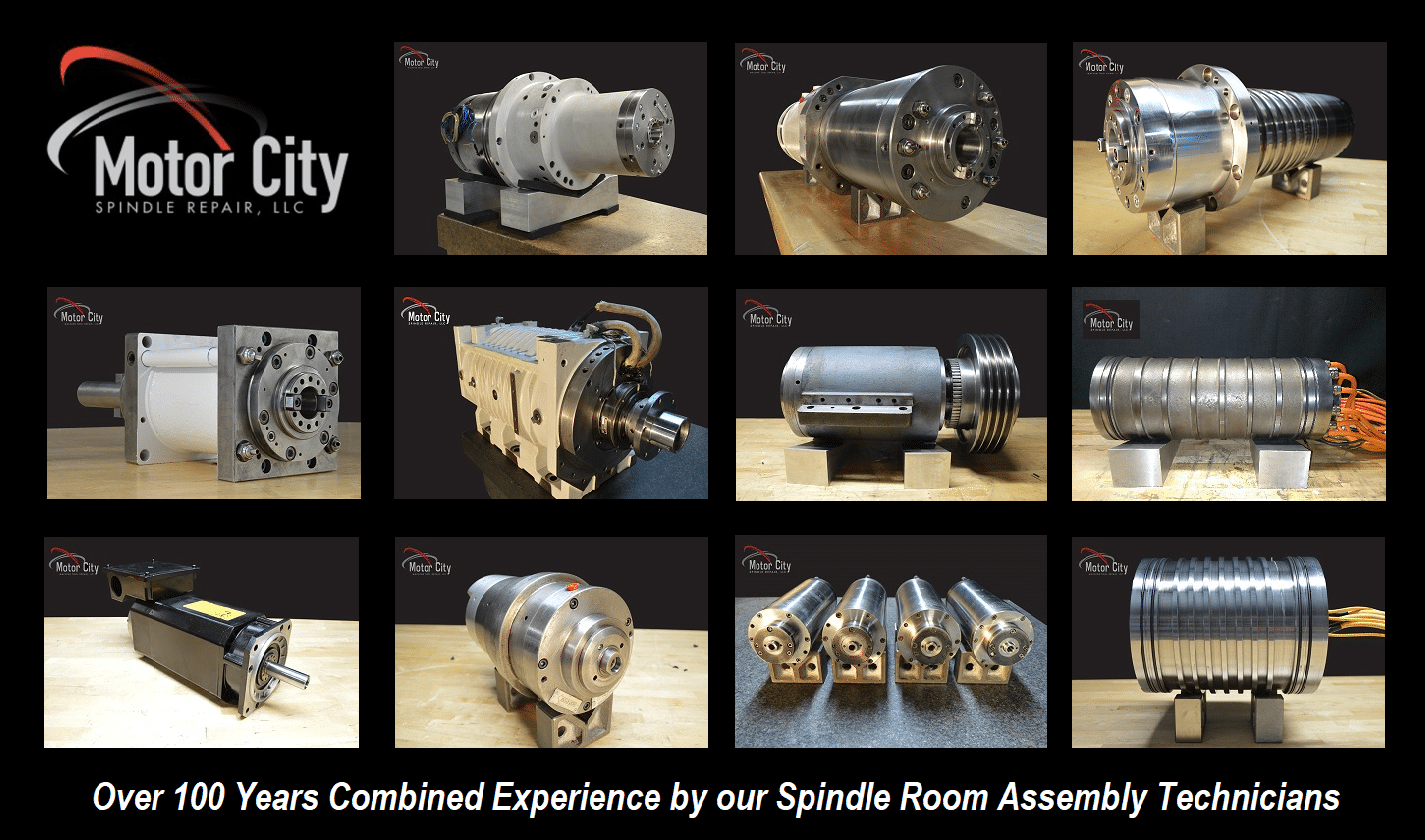

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

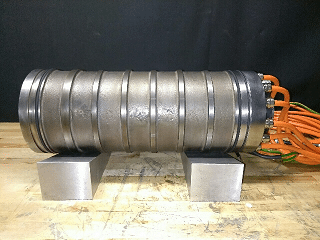

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

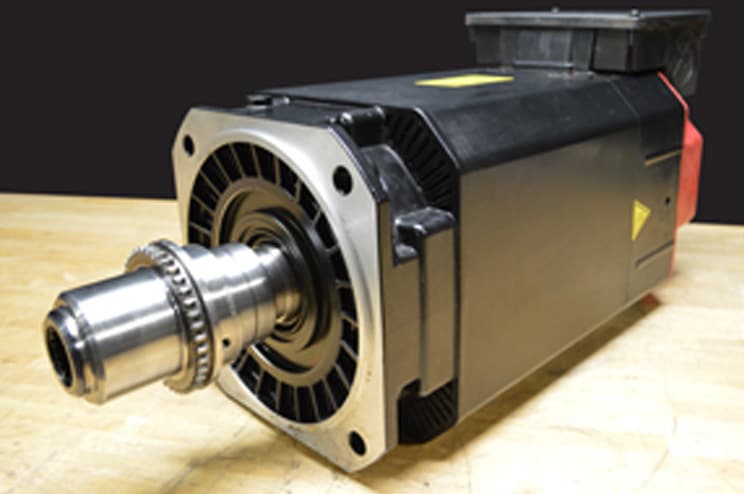

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

- Motor City Spindle Repair has 157+ Years Experience in Our Spindle Room

- 24/7 Emergency Spindle Repair Services

- Eight Full Time Spindle Assembly Technicians

- Free Evaluations and Free Delivery Services

- All Spindles Certified and Tested with a Full 1 Year Warranty

- Free Estimates Over the Phone in Seconds

- In House Machining and Grinding Capabilities

- On-site Spindle Repair Service

- Currently performing 60-70 Spindles In House Per Month

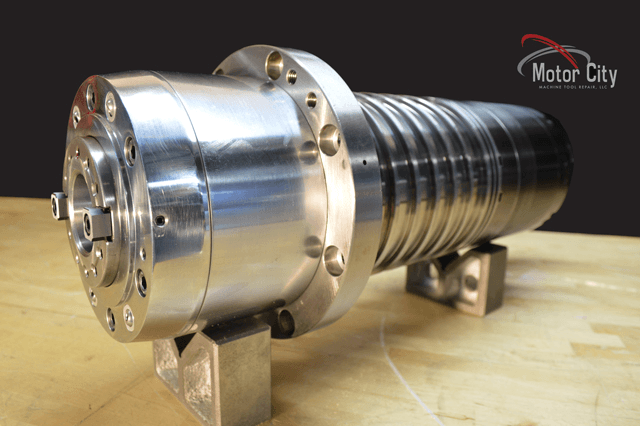

High Speed Grinding Spindle Repair Services

VMC Spindle Repair Service

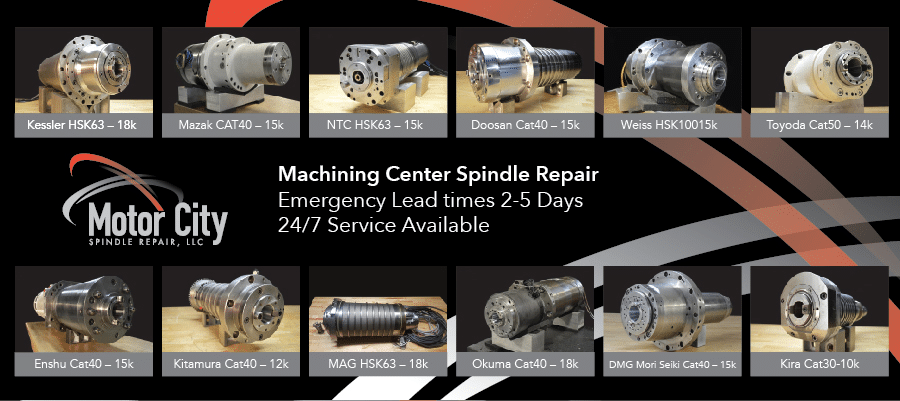

Mazak Spindle Repair Services by The Motor City Spindle Repair Team

Mazak Spindle Repair. Turning Center Spindle Repair Services by The Motor City Spindle Repair Team.

Enshu Spindle Repair Services by The Motor City Spindle Repair Team

Doosan Spindle Repair Services by The Motor City Spindle Repair Team

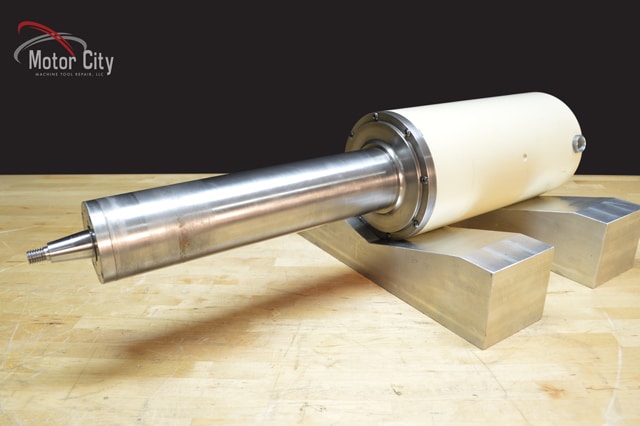

Belt Driven Spindle Repair

Spindle Motor Repair Services

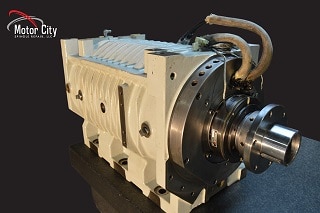

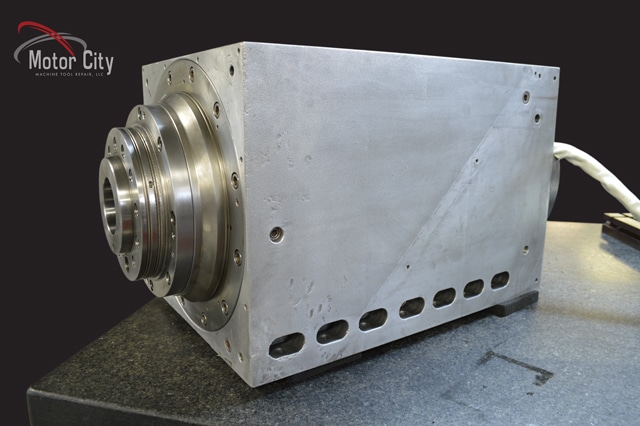

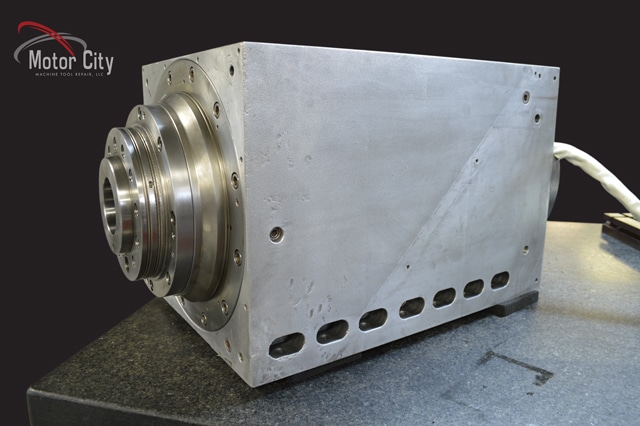

Block Spindle Repair Services

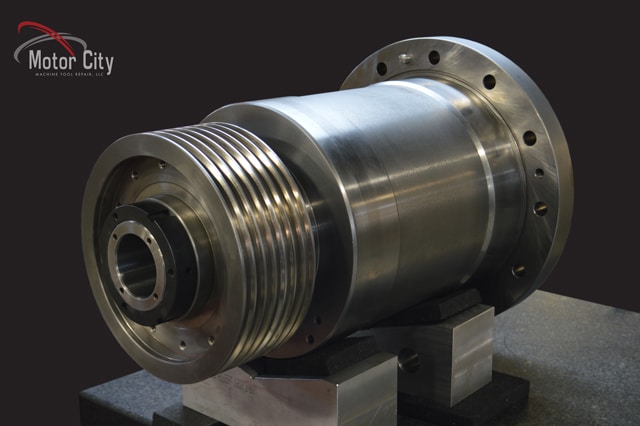

High Speed Spindle Repair Services

Grinding Spindle Repair Services

Motorized Spindle Repair Services

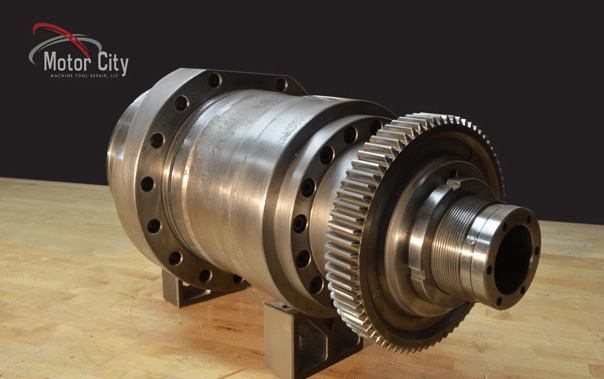

Gear Driven Spindle Repair Services

Spindles Rebuilt by The Motor City Spindle Repair Team

Weiss Spindles Rebuilt by The Motor City Spindle Repair Team

Spindle Repair Delivery Services To Go

Hermle / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

DMG Mori / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

Hardinge Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

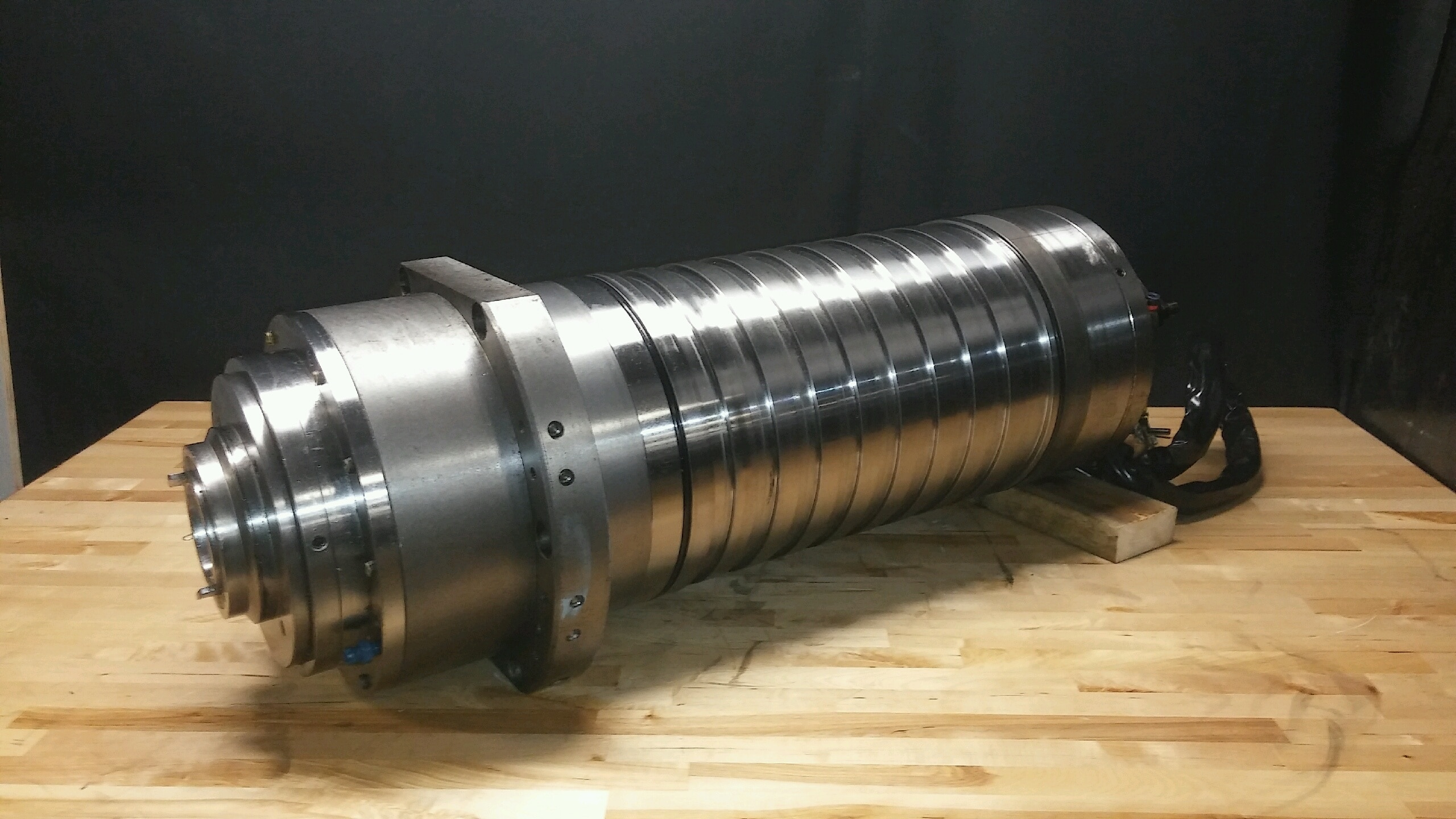

Hessapp Motorized Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

ExCello / Weiss Spindle Repair Services by The Motor City Spindle Repair Team

Okuma Spindle Repair Services by The Motor City Spindle Repair Team

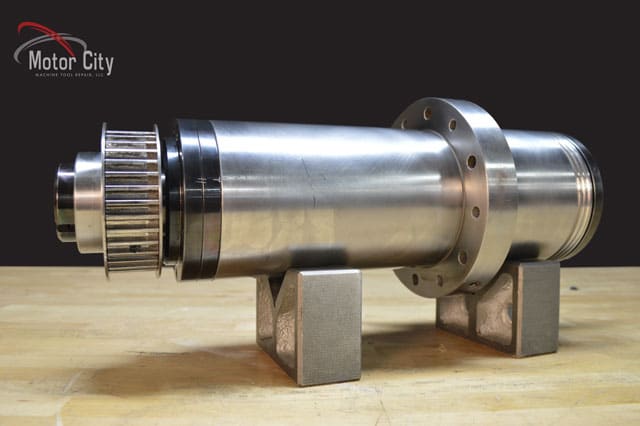

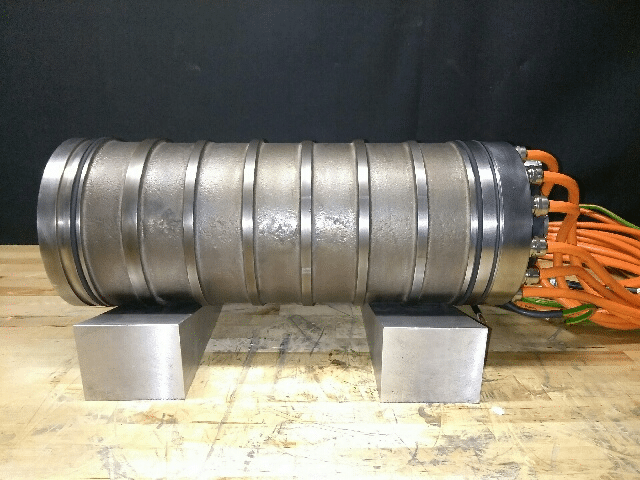

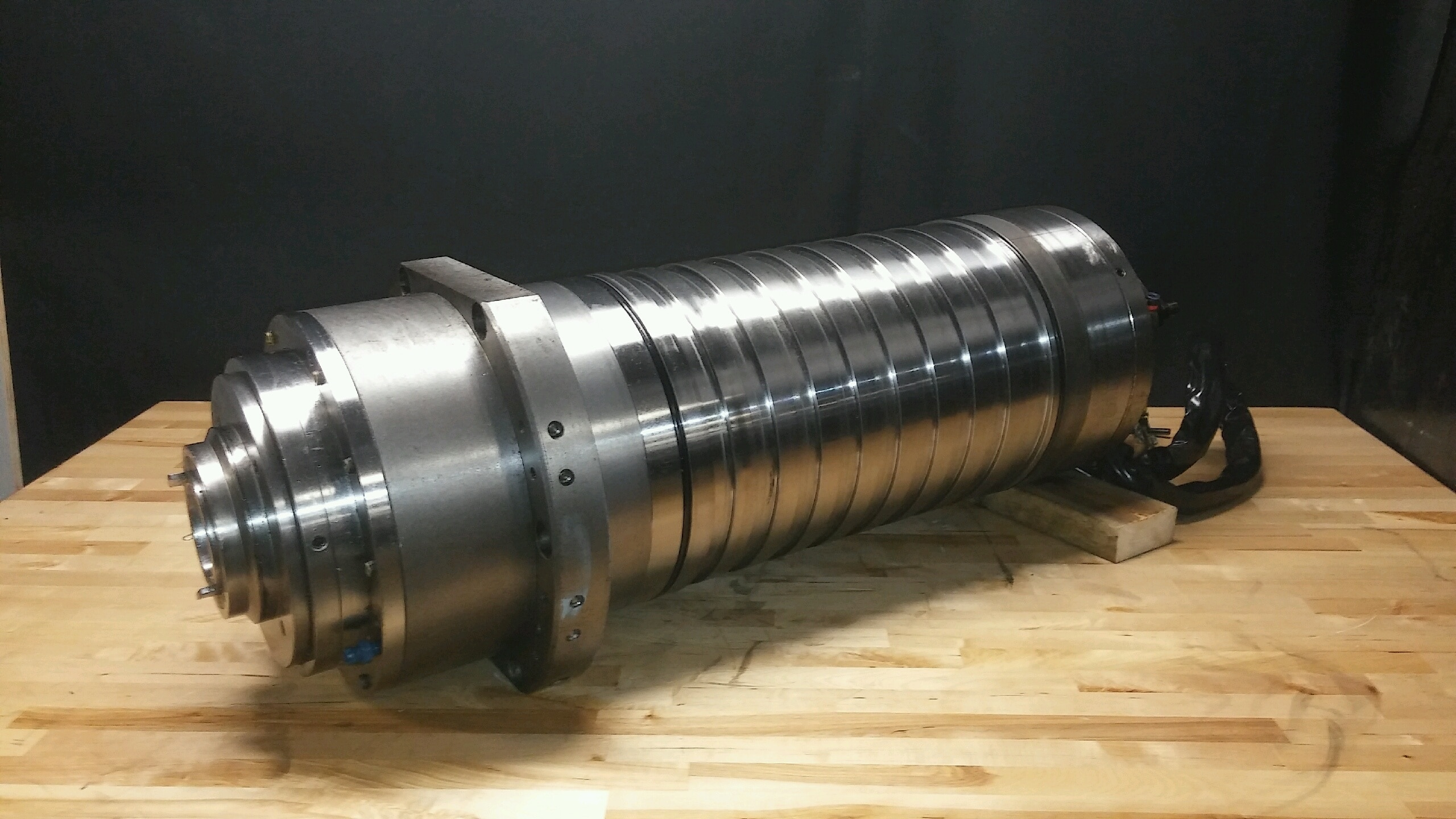

Example of a GMN Spindle Repair Rebuilt by Motor City Spindle Repair

DMG Mori Seiki Spindle Repair Services by The Motor City Spindle Repair Team

Free spindle Repair Estimates

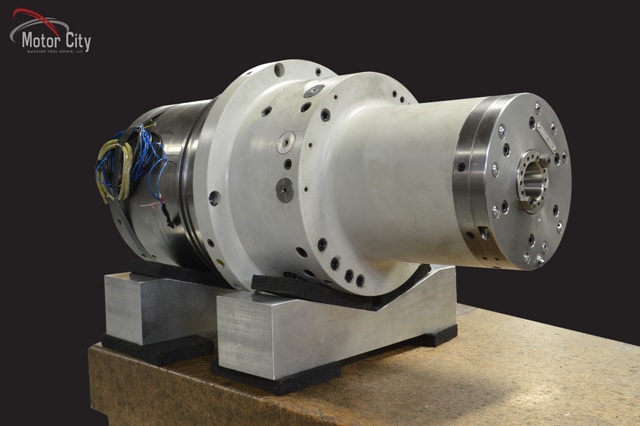

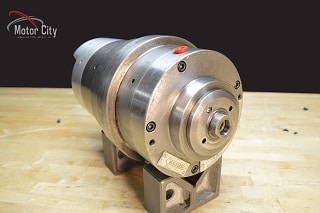

Example of a Fanuc Spindle Motor Rebuilt by Motor City Spindle Repair

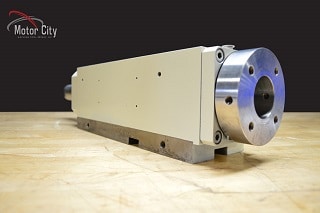

Example of a Spindle Rebuilt and Tested by Motor City Spindle Repair

NTC Spindle Repair Services by The Motor City Spindle Repair Team

Comau / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

Example of a Kira Spindle Repair Rebuilt by Motor City Spindle Repair

Fuji Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

Example of Machining Centers Spindle Repaired and Rebuilt by Motor City Spindle Repair

Over 100 Years Experience in Our Spindle Room

Emergency spindle repair service

Example of Hermle Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Hessapp Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a OKK Spindle Repair Rebuilt by Motor City Spindle Repair

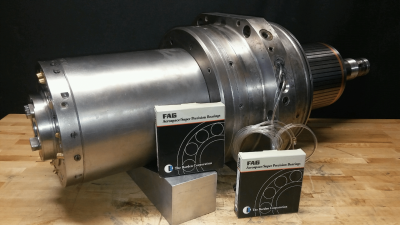

Example of a Kessler Machining Center Spindle In house by Motor City Spindle Repair