Does Age Matter When It Comes to CNC Machine Tools?

The short answer: age matters but condition matters more.

For maintenance managers and operations leaders, the real question isn’t how old the machine is. It’s whether that machine is still delivering accuracy, reliability, and production efficiency.

Let’s break it down.

The Myth: Newer Is Always Better

It’s easy to assume that a newer CNC machine automatically means better performance. And yes, modern machines offer advantages:

-

Faster processors

-

Improved control systems

-

Enhanced automation capabilities

-

Energy efficiency upgrades

But newer doesn’t always mean more productive. Especially if: preventative maintenance has been ignored, spindles haven’t been serviced properly ball screws are worn, and way systems are deteriorating. We’ve seen 20-year-old machines outperform five-year-old machines simply because they were maintained correctly.

The Reality: Wear Components Tell the True Story

A CNC machine’s age becomes relevant when wear components are neglected.

The components that truly determine performance include:

-

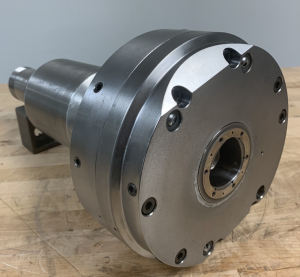

Spindles

-

Ball screws

-

Linear guides / box ways

-

Drive systems

-

Cooling and lubrication systems

These components are the heartbeat of the machine. If they’re maintained, rebuilt, or replaced proactively, an older machine can run like new. If they’re ignored, even a relatively new machine can become unreliable fast.

When Age Starts to Matter

There are specific scenarios where age does begin to impact decision-making:

1. Parts Availability

As machines get older, OEM parts can become obsolete or extremely expensive. This is where rebuild and reverse engineering capabilities become critical.

2. Control System Limitations

Outdated control platforms can restrict programming capabilities, integration with automation, or compatibility with modern tooling strategies.

3. Structural Fatigue

Machines that have run heavy cuts for decades may develop casting stress, alignment issues, or geometric inaccuracies that go beyond typical rebuild work. In these cases, age isn’t the sole issue, cumulative wear is.

The Cost Comparison: Replace vs. Rebuild

Many shops jump straight to replacement when a machine hits a certain age milestone.

But here’s what should really be evaluated:

-

Downtime cost of replacing the machine

-

Lead time for new equipment

-

Installation and training costs

-

Electrical and foundation modifications

-

Loss of production during changeover

Often, rebuilding a spindle or remanufacturing ball screws is a fraction of the cost, and dramatically faster than waiting on new equipment. A properly rebuilt spindle can restore performance to OEM specifications without the capital expenditure of a new machine.

Preventative Maintenance Extends Machine Life

So… Does Age Matter?

Yes, but not in the way most people think. Age is a data point. Condition is the real indicator. Maintenance history is the deciding factor. A 25-year-old machine with a freshly rebuilt spindle and precision-ground components can outperform a newer machine that’s been run hard and neglected.

Why CNC Shops Trust Motor City Spindle Repair

At Motor City Spindle Repair, we work with shops running brand-new equipment and machines that have been in production for decades.

Our team provides:

-

Precision spindle rebuilds

-

CNC machining and grinding services

-

ID/OD grinding

-

Surface grinding

-

Reverse engineering capabilities

-

Free estimates

We help maintenance managers extend machine life, reduce downtime, and make smart financial decisions about rebuild vs. replace. Because sometimes the smartest investment isn’t buying new, it’s restoring what you already have.

If you’re evaluating the condition of your CNC equipment and wondering whether age is becoming a liability, reach out for a free estimate. Let’s determine whether a rebuild can give your machine years of additional life. 💪

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE