EATING THE SPINDLE CORE: When & Why

4 REASONS WHY CNC COMPANIES

“EAT THE CORE“

First let’s define the term “Eat the Core” and what it means with regard to cnc machine tool spindles. To “Eat The Core” simply means to not ship a broken spindle back to the OEM when ordering “Spindle Exchange”. End Users often do this for several reasons.

CNC Machine Tool OEMs are known for their high spindle repair pricing and the cost of new spindles are often excessive. Since CNC end users can order a “spindle exchange” for significantly less than a new spindle they do so to get back up and running immediately. And they do not have to buy a new spindle. So they decline to return their broken spindle to the OEM.

Yes, this costs them the amount of money they’d receive from sending the spindle back for the core refund but this is done to save money on the ability to work with any spindle repair company they select. It give them the freedom to make their own decisions and not be held captive exclusively to the OEM.

WHEN YOU SHOULD CONSIDER

“EATING THE CORE“

if you OWN MULTIPLE CNC MACHINES / SAME MODEL

CNC MACHINES are critical TO your PROFITABILITY

if you experience FREQUENT SPINDLE FAILURE

don’t want to pay OEM PRICING

ask a spindle expert!

If you run CNC Machine Tools reach out to anyone on the Motor City Spindle Repair Team.

We have the extensive knowledge to assist all your spindle repair needs. Even if we don’t service your exact CNC machine tool make / model we can provide you with a free consultation on how to best service and maintain yourCNC spindles. Our company employees many of the most experienced CNC spindle technicians in the industry many with over 20 and even 30 years of experience that have worked for many of the world’s largest CNC machine tool OEMs and spindle OEMs in the world.

Thank you for reading and we can be reached at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

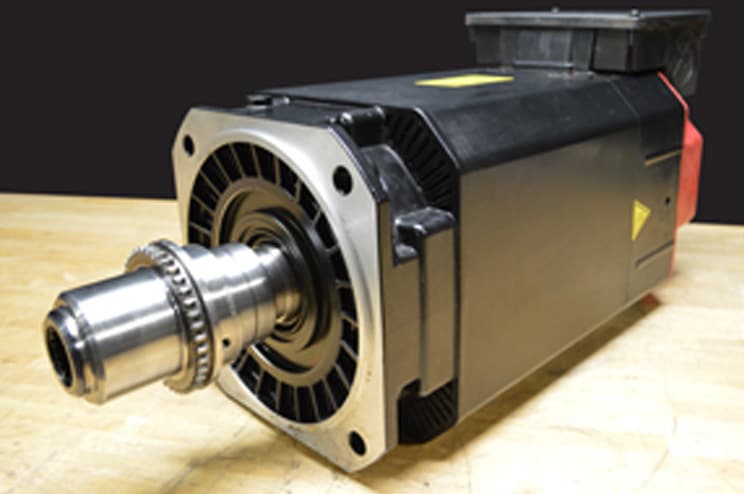

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

- Motor City Spindle Repair has 157+ Years Experience in Our Spindle Room

- 24/7 Emergency Spindle Repair Services

- Eight Full Time Spindle Assembly Technicians

- Free Evaluations and Free Delivery Services

- All Spindles Certified and Tested with a Full 1 Year Warranty

- Free Estimates Over the Phone in Seconds

- In House Machining and Grinding Capabilities

- On-site Spindle Repair Service

- Currently performing 60-70 Spindles In House Per Month

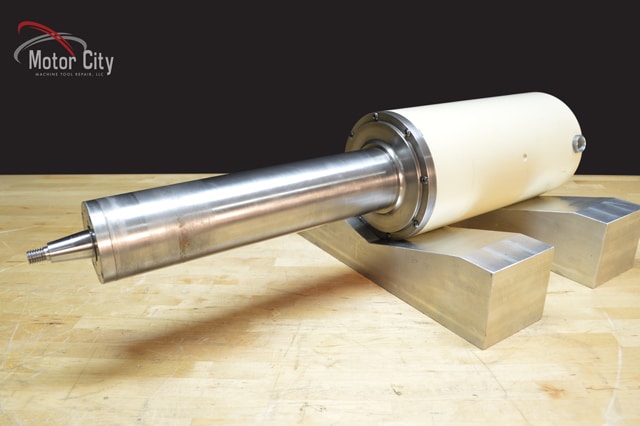

High Speed Grinding Spindle Repair Services

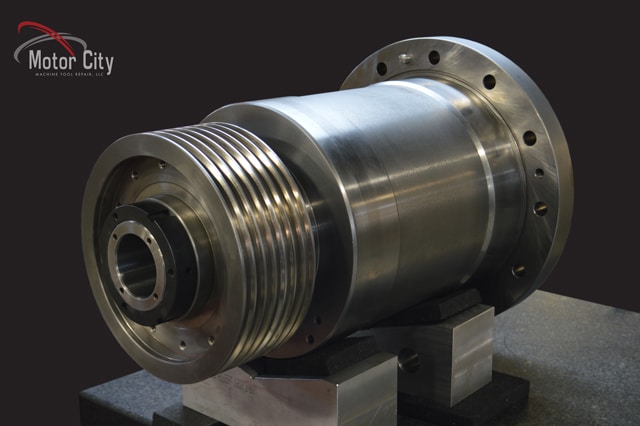

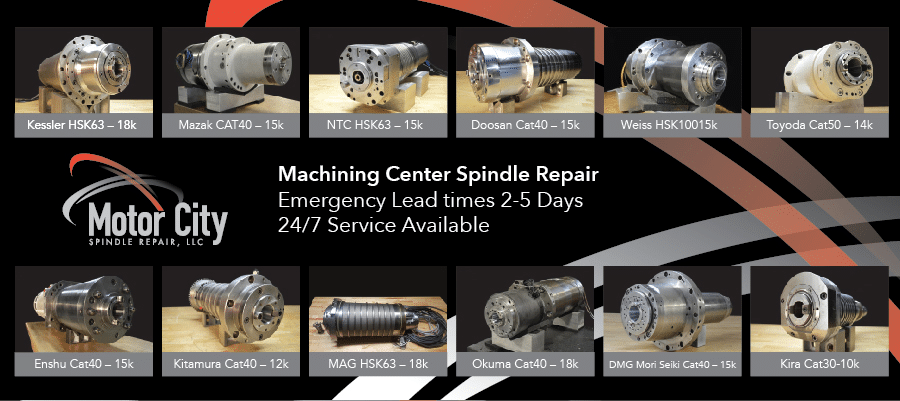

VMC Spindle Repair Service

Mazak Spindle Repair Services by The Motor City Spindle Repair Team

Mazak Spindle Repair. Turning Center Spindle Repair Services by The Motor City Spindle Repair Team.

Enshu Spindle Repair Services by The Motor City Spindle Repair Team

Doosan Spindle Repair Services by The Motor City Spindle Repair Team

Belt Driven Spindle Repair

Spindle Motor Repair Services

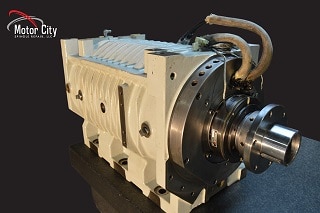

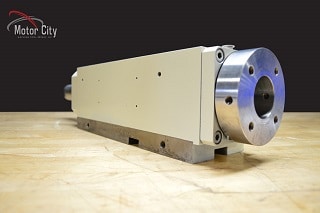

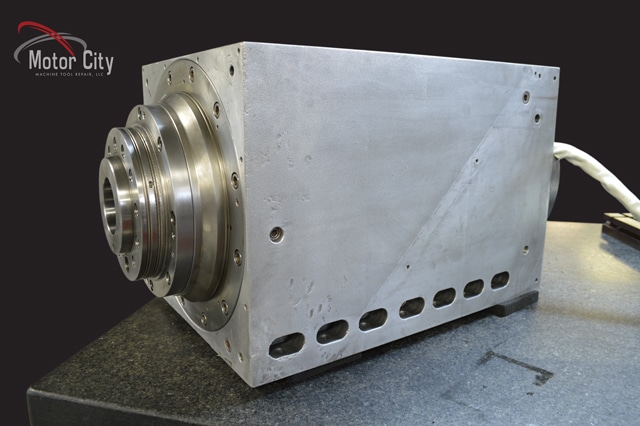

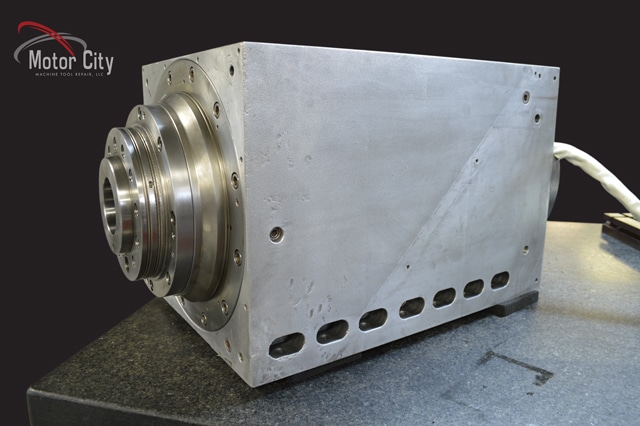

Block Spindle Repair Services

High Speed Spindle Repair Services

Grinding Spindle Repair Services

Motorized Spindle Repair Services

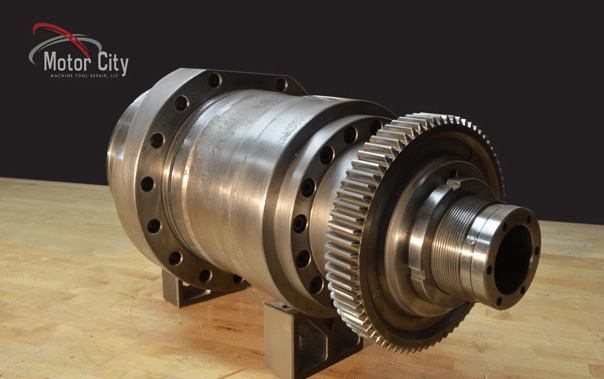

Gear Driven Spindle Repair Services

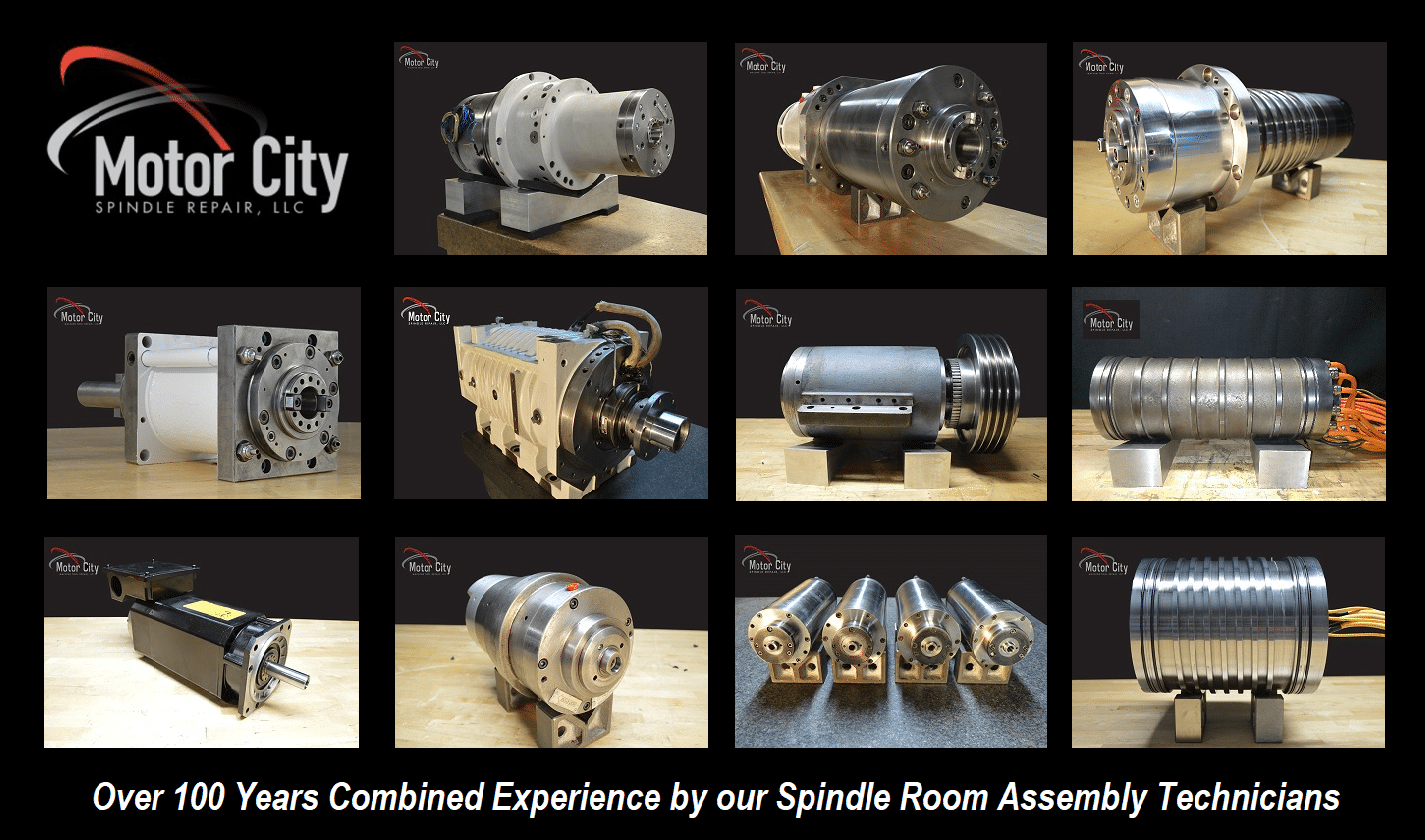

Spindles Rebuilt by The Motor City Spindle Repair Team

Weiss Spindles Rebuilt by The Motor City Spindle Repair Team

Spindle Repair Delivery Services To Go

Hermle / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

DMG Mori / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

Hardinge Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

Hessapp Motorized Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

ExCello / Weiss Spindle Repair Services by The Motor City Spindle Repair Team

Okuma Spindle Repair Services by The Motor City Spindle Repair Team

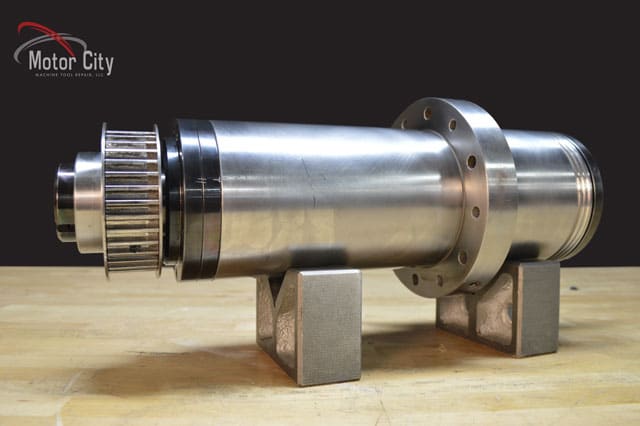

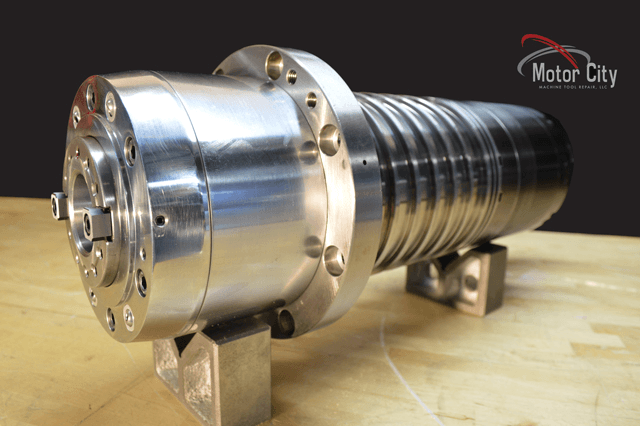

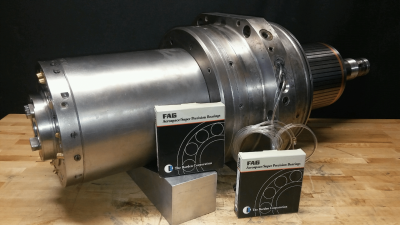

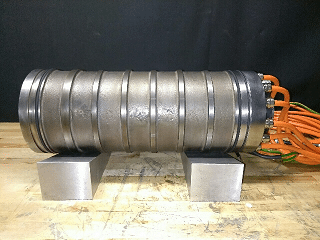

Example of a GMN Spindle Repair Rebuilt by Motor City Spindle Repair

DMG Mori Seiki Spindle Repair Services by The Motor City Spindle Repair Team

Free spindle Repair Estimates

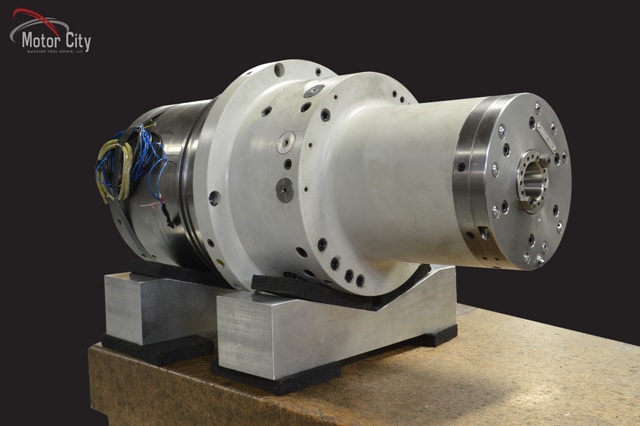

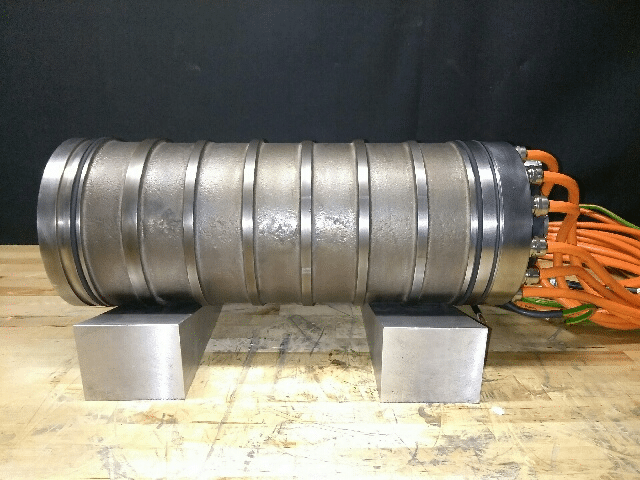

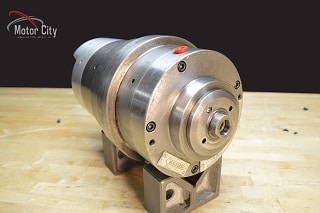

Example of a Fanuc Spindle Motor Rebuilt by Motor City Spindle Repair

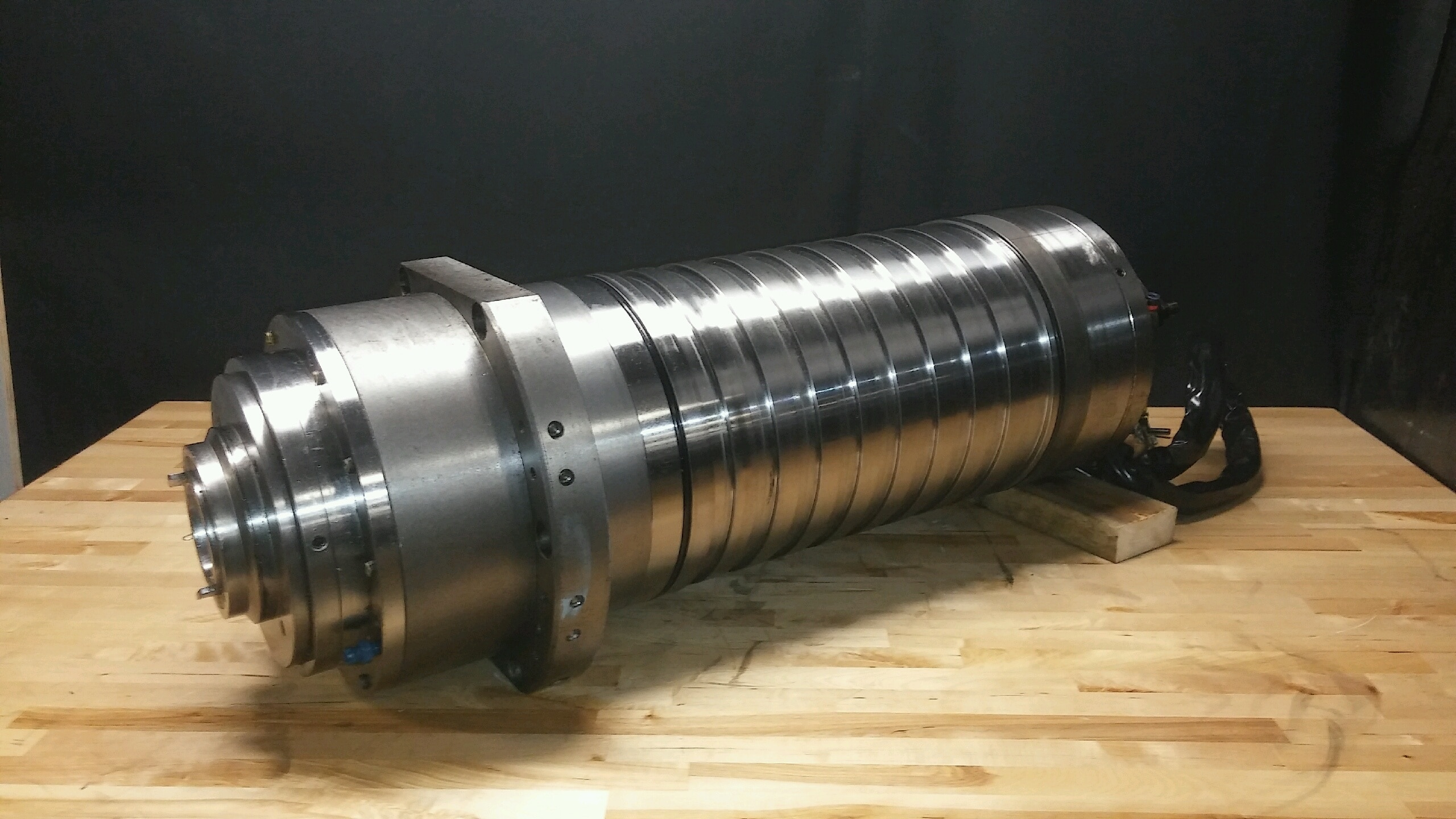

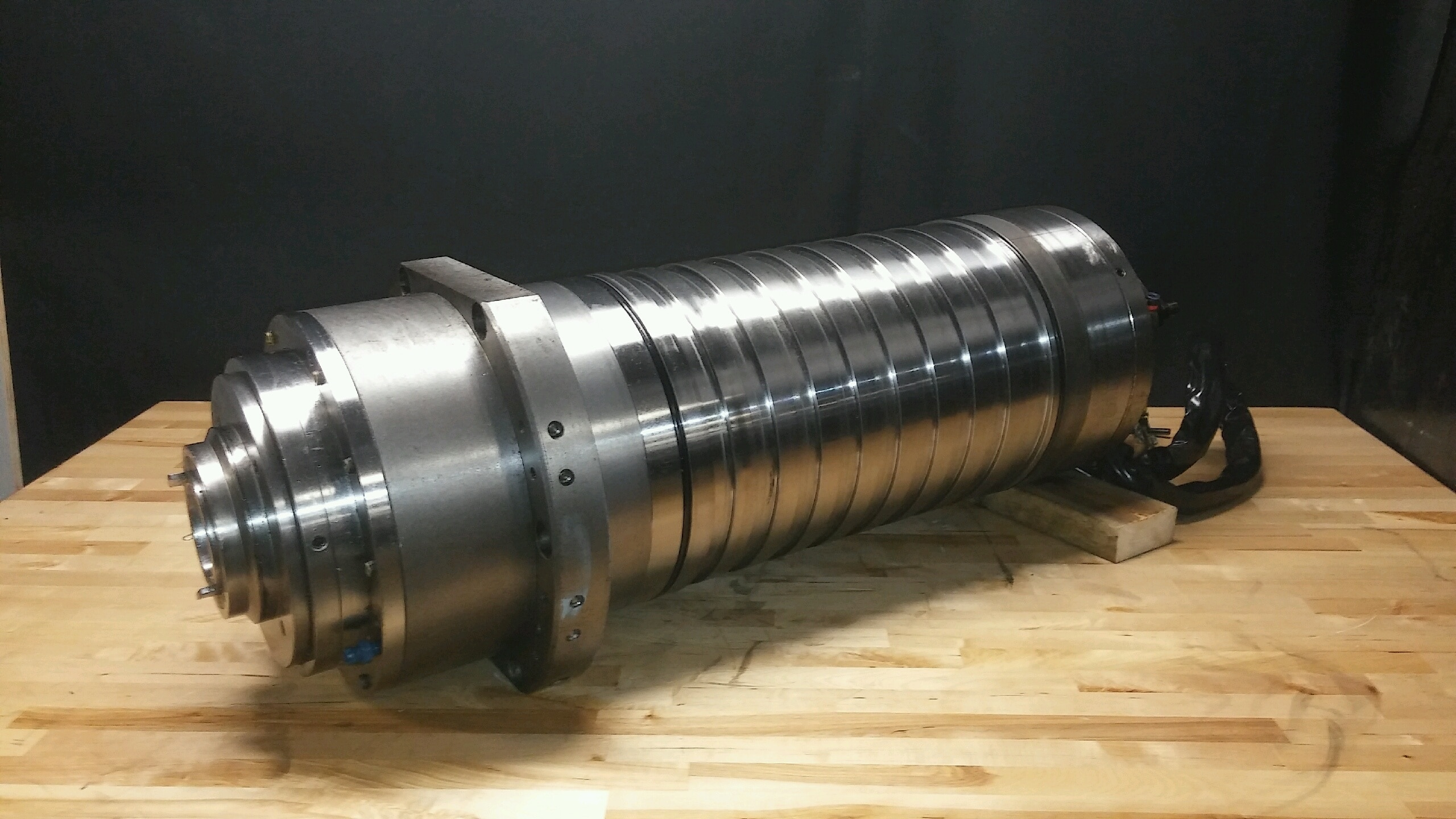

Example of a Spindle Rebuilt and Tested by Motor City Spindle Repair

NTC Spindle Repair Services by The Motor City Spindle Repair Team

Comau / Kessler Spindle Repair Services by The Motor City Spindle Repair Team

Example of a Kira Spindle Repair Rebuilt by Motor City Spindle Repair

Fuji Turning Center Spindle Repair Services by The Motor City Spindle Repair Team

Example of Machining Centers Spindle Repaired and Rebuilt by Motor City Spindle Repair

Over 100 Years Experience in Our Spindle Room

Emergency spindle repair service

Example of Hermle Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Hessapp Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a OKK Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Kessler Machining Center Spindle In house by Motor City Spindle Repair