Firing up a CNC machine is a bet on its precision, power, and reliability. But have you ever wondered if it’s built to last—or designed with a hidden expiration date? In an age of disposable tech, are these machines engineered for decades of service, or designed to fail?

Fanuc

In CNC machining, precision and rigidity are key. The connection between the machine spindle and tool holder directly affects performance, accuracy, and surface finish.

Exploring the Pinnacle of Precision: The Most Popular CNC Machining Centers In the realm of manufacturing, precision is paramount. From…

PREVENTATIVE MAINTENANCE Implementing a preventative maintenance program for your CNC machine tool machining facility is essential to ensure optimal performance,…

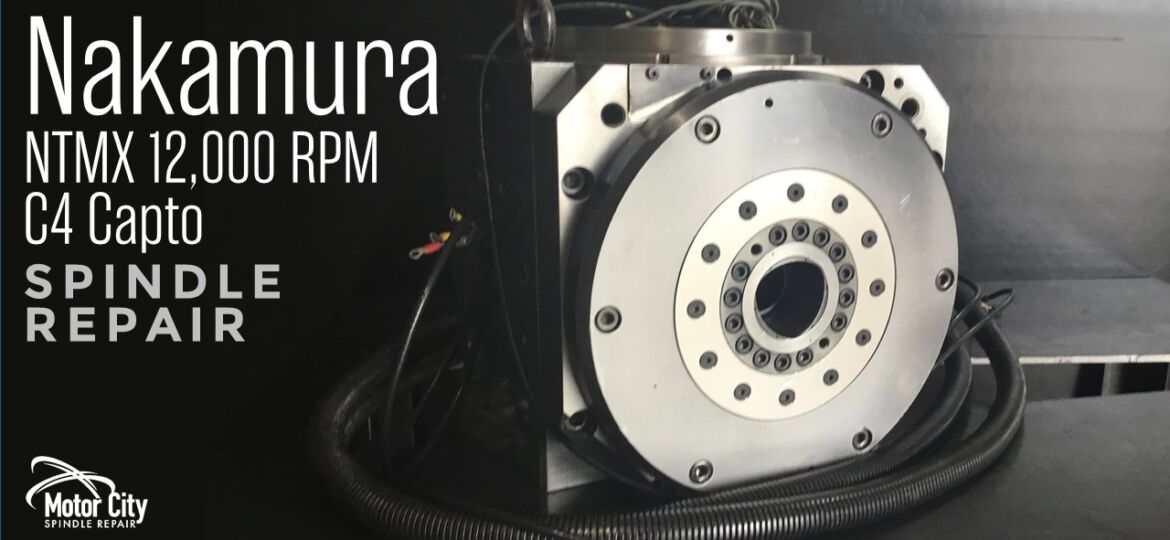

If you send us a Fanuc Robodrill spindle to repair, we have the ability to do an upgrade on your unit to make it last longer in your machine tool. If you’re currently running your spindle at 10k rpm, we can upgrade it to run at 24k rpm by replacing the current bearings with a set of angular contact bearings.

COMMON CNC SPINDLE UPGRADES Are you interested in lengthening the overall life of your machine tool spindle? Motor City Spindle…