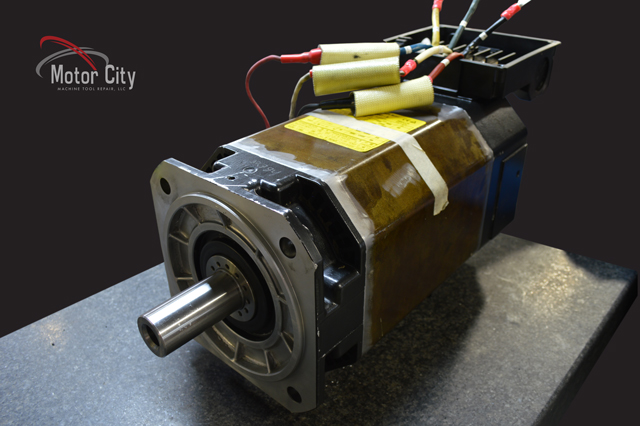

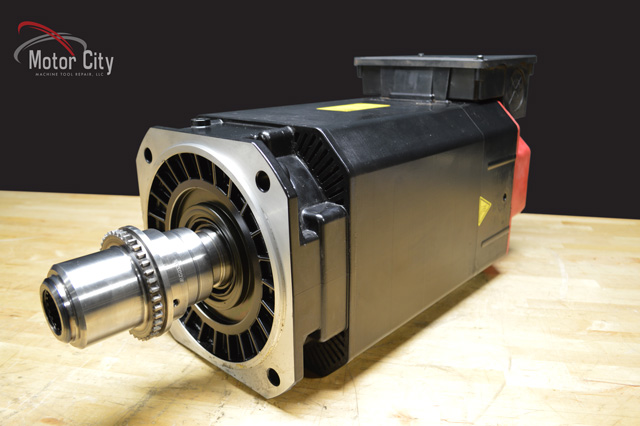

Motor City Spindle Repair is one of the leaders in Fanuc servo motor repair. We have repaired countless fanuc servo motors that are used on many different machines and for various applications. The technicians at our facility have many years experience with repairing, testing and fine tuning servo motors, and are very familiar with most models of the Fanuc brand. We also repair other brands of servo motors, however Fanuc is the brand we have specialized in over the years.

It takes a variety of specialized electric servo motor drives to run servo motors, and also special diagnostic equipment for testing. Motor City Spindle Repair utilizes this advanced equipment to test and balance Fanuc servo motors. We are capable of doing various repairs for servo motors including rewinding, replacing bearings, and replacing electronic components.

Servo Motors are used to power various components of CNC machining centers, such as driving ball screws, rotary tables, or indexing tables. These are integral parts of CNC machining centers, which must run properly for machining centers to make parts. We at Motor City Spindle Repair are able to repair these Fanuc servo motors in a timely and precise manner so that your machine can get back up and running as soon as possible.

A few of the Fanuc Motors we service include: i series, Bi series, DiS series, LiS series, ALPHAi series, ALPHAi-B series, BETAi series, BETAi-B series, BETAiSVSP-B, ROBODRILL DDR series, ROBODRILL DDR-T series, ROBOSHOT series, ROBOCUT series

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

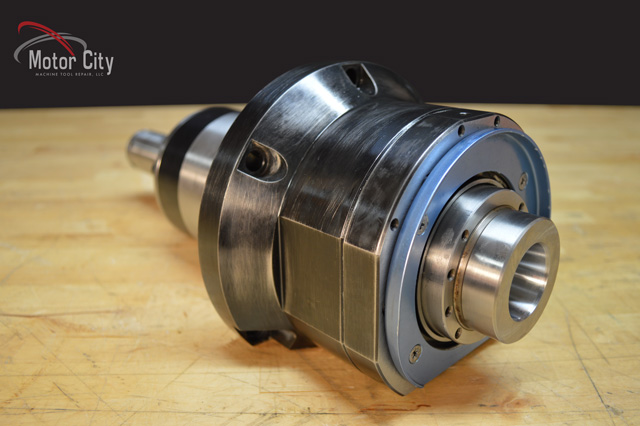

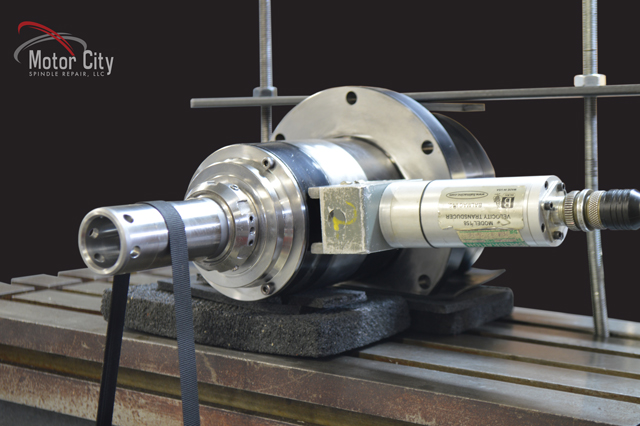

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NSK Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair