Fanuc vs Siemens: The Ultimate CNC Spindle Motor Showdown

Choosing the right spindle motor and control system is crucial for your CNC operation. Two industry leaders, Fanuc and Siemens, dominate this space. Both have spent decades refining their technology, but which one is right for your needs?

This comparison breaks down the key differences between Fanuc and Siemens spindle motors and controls, helping you make the best choice. We’ll explore performance, reliability, costs, and real-world applications to find out which comes out on top.

Understanding CNC Spindle Motors and Controls

Spindle motors drive the cutting tool, while control systems manage speed, torque, and precision. Modern systems need to deliver consistent performance under varying loads, maintain precise speed control, and operate reliably during long production runs. The control system acts as the brain, adjusting motor performance in real-time.

Fanuc: Japanese Precision

Spindle Motor Technology

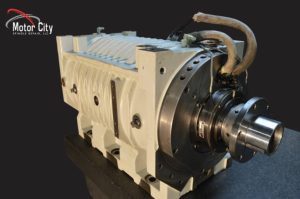

Fanuc is known for reliable spindle motors that excel in high-volume environments. Their motors feature advanced magnetic bearing technology and cooling systems to ensure consistent performance.

(Mazak Integrex with Fanuc Spindle Motor shown above)

Key features include:

- High torque-to-weight ratios

- Excellent thermal management

- Integrated encoder systems for accuracy

- Modular design for easy maintenance

Control Systems

Fanuc controls are user-friendly and reliable, with standardized features across product lines, making it easy for operators to switch between machines.

Advantages include:

- Intuitive programming

- Strong diagnostic tools

- Library of pre-programmed cycles

- Seamless automation integration

Siemens: German Engineering

Spindle Motor Innovation

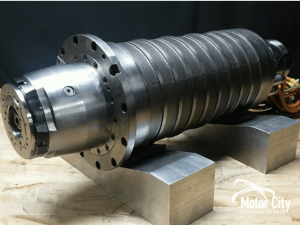

Siemens focuses on versatile, cutting-edge spindle motor designs. Their motors use advanced materials and engineering for high efficiency and precision.

(MAG Machine Tool Spindle with Weiss / Siemens Spindle Motor shown above)

Key features include:

- Advanced vector control

- Superior dynamic response

- Integrated safety features

- Flexible configurations

Common CNC Spindle Examples with Siemens Motors:

- Weiss

- Kessler

- GMN

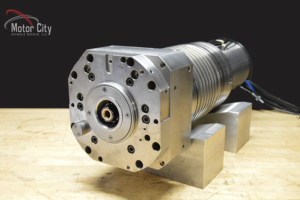

(Kessler Spindle with Siemens Spindle Motor shown above)

Control Systems

Siemens controls emphasize flexibility and advanced capabilities. Their Sinumerik platform is highly customizable and adaptable to various machining applications.

Highlights include:

- Advanced path planning algorithms

- Simulation capabilities

- Integrated quality monitoring

- Extensive connectivity options

Performance Comparison: Speed and Precision

Speed

Both Fanuc and Siemens offer high-speed spindle motors, but with different focuses. Fanuc prioritizes proven, reliable speed ranges, while Siemens pushes for cutting-edge performance. For most applications, both systems provide more than enough speed.

Precision

Fanuc excels in maintaining accuracy over long production runs, minimizing drift and keeping tight tolerances. Siemens shines in dynamic precision, compensating for rapid speed or direction changes with advanced control algorithms.

(DMG Machining Center Spindle with Siemens Motor shown above)

Reliability and Maintenance

Fanuc Reliability

Fanuc is legendary for reliability, with systems operating for years with minimal maintenance. This comes from conservative designs, rigorous testing, and high-quality components.

Siemens Reliability

Siemens focuses on advanced diagnostics and predictive maintenance, identifying potential issues before they happen.

Maintenance

Fanuc systems are easy to maintain, with straightforward procedures and widely available parts. Siemens offers more advanced diagnostics, often simplifying troubleshooting but requiring slightly more sophisticated maintenance practices.

(Siemens Motor shown above from an EMAG Turning Center)

Cost Analysis

Upfront Costs

Fanuc systems often have a lower initial cost, especially for standard setups. Siemens may require a higher upfront investment due to its advanced features.

Long-term Costs

Fanuc’s reliability translates to lower maintenance and downtime expenses. Siemens offers better energy efficiency and advanced diagnostics, reducing long-term operating costs through optimized performance.

Application-Specific Considerations

High-Volume Production

Fanuc is ideal for high-volume environments where consistency is key, with a strong reputation in industries like automotive.

Complex Machining

For advanced machining requiring flexibility, Siemens excels with its customization and control capabilities.

Integration

Both brands offer excellent integration, though Fanuc focuses on standardized methods, while Siemens provides more flexibility.

(NTC CNC Machining Center Spindle with a Fanuc Motor)

Making the Right Choice

Your decision depends on your specific needs:

Fanuc is best if you prioritize:

- Proven reliability and minimal downtime

- Simple operation and maintenance

- Consistent performance for high-volume production

Siemens is best if you prioritize:

- Advanced control and flexibility

- Cutting-edge features

- Superior diagnostics and customization

The Verdict: Excellence in Different Areas

Fanuc and Siemens both deliver exceptional spindle motors and control systems. Fanuc excels in reliability and ease of use, while Siemens leads in advanced functionality and flexibility. The right choice depends on your production needs and priorities.

Consider analyzing your requirements, consulting with both manufacturers, and testing systems in your environment. The right system will improve productivity, quality, and efficiency for years to come.

(DMG Mori Spindle known to use both Fanuc & Siemens shown above)

Why Choose Motor City Spindle Repair?

Motor City Spindle Repair is a leading provider of spindle repair services, specializing in restoring both Fanuc and Siemens spindle motors to optimal performance.

Our technicians have extensive experience and advanced training, ensuring that your equipment is handled with precision and care. By using state-of-the-art diagnostic tools and repair techniques, we can quickly identify and address issues, minimizing downtime and maximizing productivity.

Additionally, Motor City Spindle Repair prioritizes quality, offering rigorous testing and calibration to ensure repaired spindles meet or exceed OEM specifications. This commitment to excellence makes us a trusted partner for keeping your operations running smoothly.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE