The Science of Heat Management in High-Speed CNC Machining

High-speed CNC machining is a marvel of modern manufacturing, capable of shaping metal with incredible speed and precision. As spindle speeds and material removal rates increase, these machines push the limits of what’s possible. However, this process generates a powerful byproduct: heat. If unmanaged, heat can compromise precision and efficiency. Understanding heat generation and management is vital for optimizing operations.

This post explores the science of heat in CNC machining, including its causes, challenges, and practical solutions. Managing heat effectively protects tools, ensures workpiece quality, and boosts productivity.

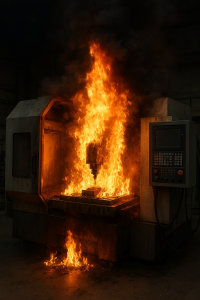

Why Excessive Heat is a Problem![]()

Heat in machining is more than an inconvenience—it’s a destructive force, impacting both tools and workpieces.

Tool Life

Cutting tools endure the most heat during machining. High temperatures soften tool material, causing rapid wear. Common heat-related issues include:

- Abrasive Wear: Dulling of the cutting edge.

- Cratering: Chips welding to the tool and tearing away material.

- Deformation: Tools bending under extreme heat and pressure.

These issues shorten tool life, leading to frequent replacements, downtime, and higher costs.

Workpiece Quality

Excess heat causes thermal expansion, making precision tolerances harder to achieve. A part machined at high temperatures may shrink or distort as it cools, falling outside acceptable specs. Localized heat can also harden or warp materials, leading to poor finishes, rework, or scrapped parts.

Where Heat Comes From

Heat during machining is primarily generated in three areas:

- Shear Zone: The main source of heat, where metal is deformed into chips.

- Tool-Chip Interface: Friction as chips slide against the cutting tool.

- Tool-Workpiece Interface: Friction between the tool and the machined surface.

Ideally, most heat is carried away with the chip, but in high-speed machining, heat often transfers into the tool and workpiece.

Strategies for Effective Heat Management

Managing heat requires applying proven scientific principles. Key strategies include:

1. Use Coolants (Heat Removal)

Coolants absorb heat from the cutting zone through convection. Common methods include:

- Flood Coolant: High-volume streams cool and lubricate.

- Through-Spindle Coolant (TSC): Delivers coolant directly to the cutting edge for deep holes or complex pockets.

- Minimum Quantity Lubrication (MQL): Uses a fine mist of oil and air for lubrication, ideal for certain applications like aluminum machining.

2. Advanced Tool Coatings

Modern tools use coatings like Titanium Aluminum Nitride (TiAlN) or Aluminum Chromium Nitride (AlCrN), which act as thermal barriers. These coatings insulate the tool, reduce friction, and resist wear, allowing for higher speeds and feeds.

3. Optimize Cutting Parameters

Adjusting speeds, feeds, and depth of cut can control heat generation. Key tactics include:

- Feed Rate: Higher feed rates produce thicker chips that carry away more heat.

- Chip Thinning: Avoid heat-generating “rubbing” by increasing feed rates when using small radial cuts.

- Cutting Speed: Balancing speed to remove material quickly while minimizing heat transfer to the tool and workpiece.

Conclusion: Managing Heat for Better Results

Controlling heat in high-speed CNC machining is essential for quality, efficiency, and profitability. Evaluate your processes: Are you using the right coolant, tools, and cutting parameters? By combining effective cooling, advanced tool tech, and optimized programming, you can protect your tools, improve workpiece quality, and maximize machine performance.

Why Trust Motor CitySpindle Repair?

CNC spindle health is critical for heat management and long-term success. Motor City Spindle Repair provides expert diagnostics, comprehensive repairs, and preventative maintenance to keep your spindles performing at their best. With nationwide support and fast turnaround times, they ensure your machines run smoothly and reliably. Choose Motor City Spindle Repair for dependable service and optimized machining performance.

Prolonged Machine Life: Our repairs prevent downtime and future issues.

- Emergency Services: Quick repairs to minimize disruptions.

- Expert Team: Skilled technicians handle all spindle brands and configurations.

- Warranty Protection: One-year in-service warranty for peace of mind.

- Precision Testing: Repairs exceed OEM specifications for optimal performance.

Count on us for reliable service, fast turnarounds, and precision that keeps your machines running at their best.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE

Prolonged Machine Life: Our repairs prevent downtime and future issues.

Prolonged Machine Life: Our repairs prevent downtime and future issues.