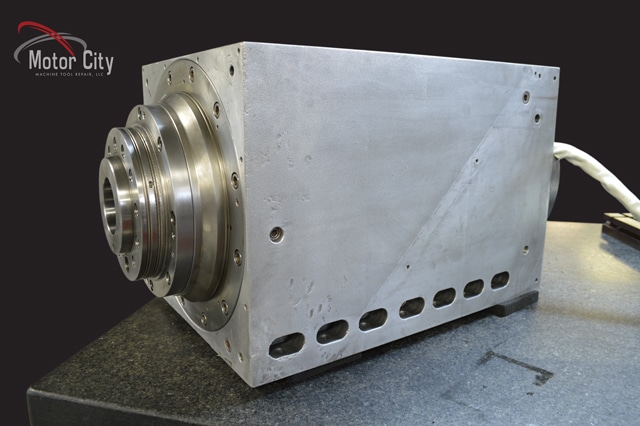

The Hessapp DVT Series Turning Center Spindle was sent to Motor City Spindle Repair, after the Spindle failed during production. Once received, our team quickly inspected, disassembled, and quoted the customer for the work needed to repair the spindle. After testing the Spindle Motor it was found that the Hessapp Spindle failed because the Motor Winding had shorted out. The short is suspected to be caused by coolant entering the spindle, due to a seal having damage to it. The coolant contamination was also found to have caused damage to some of the bearings. The Spindle Stator was rewound, washed, and baked. New sets of Bearings were ordered, to replace the old ones. Once all components were ready, one of our Experienced Spindle Technicians (with an average of 20 years experience) rebuilt this spindle. The DVT Spindle was balanced, then test run for four hours at the Max RPM. Before it was shipped back to the customer, the spindle was running flawlessly.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com