Why Aerospace Shops Require Higher Spindle Precision: A Tolerance Breakdown

I

This post explores the critical role of high spindle precision in aerospace. We’ll examine why tight tolerances are essential, highlight key components requiring extreme accuracy, and discuss how advanced spindle technology helps manufacturers meet these exacting standards.

The Need for Extreme Tolerances

A tolerance is the allowable variation in a part’s dimensions. In most industries, a few thousandths of an inch may suffice. In aerospace, tolerances often measure in microns—one-millionth of a meter. This precision ensures components can withstand intense vibrations, temperature changes, and aerodynamic forces without failure. Even minute deviations can create weak points, leading to material fatigue, cracks, or catastrophic failure. With human lives at stake, safety and performance leave no margin for error.

Key Components Requiring Higher Precision

Turbine Blades

Turbine blades endure extreme heat and thousands of rotations per minute inside jet engines. Their complex airfoil shapes must be flawless to optimize airflow, efficiency, and performance. Dimensional errors can disrupt airflow, increase fuel consumption, or cause vibrations that lead to engine failure. Precision spindles with minimal runout and dynamic stability ensure these parts meet exacting standards.

Landing Gear

Landing gear components must handle immense energy during landings. Hydraulic cylinders, structural elements, and locking mechanisms require perfect fits to ensure smooth, reliable operation. Poor tolerances can cause hydraulic leaks, binding, or uneven stress, compromising safety. Robust, high-precision spindles enable the accurate machining these components demand.

Fuselage and Structural Parts

Fuselage panels, wing spars, and other structural parts must fit seamlessly to form strong, aerodynamic airframes. Misalignments can create drag, reduce fuel efficiency, and concentrate stress, increasing the risk of failure. Spindles with consistent accuracy over complex contours and long paths are essential for machining these large, lightweight components.

Advanced Spindle Technology: Overcoming Challenges

Achieving micron-level precision is no small task, especially with tough aerospace materials like titanium, Inconel, and composites. These materials generate heat, wear tools quickly, and place high demands on spindles. Advanced spindle technology addresses these challenges:

- High Speeds: Advanced spindles achieve high RPMs for faster material removal and smoother finishes, especially with small tools.

- Rigidity and Damping: Stiff designs minimize deflection under heavy loads, while vibration-damping reduces chatter and extends tool life.

- Thermal Stability: Sophisticated cooling systems maintain accuracy during heat-generating operations.

- Minimal Runout: Precision bearings and balancing keep runout near zero, ensuring cutting tools follow exact paths.

The Value of Precision![]()

For aerospace manufacturers, investing in high-precision spindles is crucial. Benefits include:

- Safety and Reliability: Meeting stringent standards enhances passenger and crew safety.

- Efficiency: Precisely manufactured components improve fuel economy, range, and reliability.

- Cost-Effectiveness: Reduced scrap, rework, and downtime lower overall costs while boosting productivity.

Precision is the foundation of aerospace safety and performance. From raw material to finished part, the spindle plays a critical role in delivering flight-ready components. By investing in advanced spindle technology, aerospace shops ensure their ability to produce high-quality, reliable parts.

Partnering with the Aerospace Industry for Precision and Reliability

Aerospace manufacturing requires machining exotic alloys and intricate components to extremely tight tolerances. This demands spindles that are both powerful and precise. Our technicians specialize in repairing high-speed, high-torque spindles used in 5-axis machining centers, gantry mills, and other critical equipment. We restore spindles to or beyond OEM specifications, ensuring your machinery produces parts that meet strict industry and regulatory requirements.

Why choose Motor City Spindle Repair?

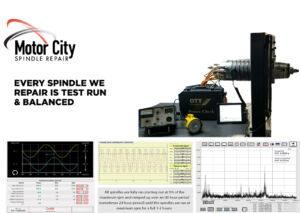

- Quality You Can Trust: Every spindle is repaired in a clean, climate-controlled environment to prevent contamination and ensure precisio

n. We balance all rotating components to ISO standards, reducing vibration and extending spindle life.

- Fast Turnaround: Downtime affects your production and bottom line. Our efficient repair process minimizes delays, getting your machinery back online quickly.

- Specialized Expertise: With years of experience in high-tech industries, we understand the challenges aerospace manufacturers face. Our skilled technicians diagnose complex spindle failures and implement lasting solutions.

By partnering with Motor City Spindle Repair, you gain a trusted ally committed to the success of your manufacturing processes. We deliver the reliability and precision your operations demand, helping you stay competitive in the aerospace industry.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE

n. We balance all rotating components to ISO standards, reducing vibration and extending spindle life.

n. We balance all rotating components to ISO standards, reducing vibration and extending spindle life.