How to Choose the Right Spindle Repair Shop

A failing spindle can halt production, scrap parts, and quickly erode margins. Choosing the right spindle repair shop is key to protecting uptime, accuracy, and tool life. But not all shops are the same. The best providers combine certified quality systems, advanced equipment, and thorough testing. They also communicate clearly, document their work, and back up their repairs.

This guide outlines what to look for—certifications, equipment, testing capabilities—so you can confidently choose a spindle repair partner.

Key takeaways:

- Choose shops with recognized quality certifications and OEM approvals where applicable.

- Confirm they have precision equipment for balancing, grinding, and diagnostics.

- Insist on data-backed testing like vibration analysis, runout, thermal growth, and load testing.

Why the Right Spindle Repair Shop Matters

Spindles are critical to machining accuracy. Poor repairs can cause issues like runout, imbalance, thermal drift, or premature bearing failure, resulting in:

- Dimensional errors and poor surface finishes

- Reduced tool life and chatter

- Unplanned downtime and repeat repairs

- Higher overall costs

On the other hand, a quality repair restores OEM performance, extends spindle life, and ensures consistent machining results. The right shop doesn’t just fix the spindle—they address root causes, correct problems, and validate repairs under real-world conditions.

Certifications to Look For

Certifications ensure standardized processes and quality control. While not the full picture, they reduce risk:

ISO Certifications

- ISO 9001: Indicates standardized processes, corrective actions, and ongoing improvements.

- ISO 17025 (less common): Shows competence in testing and calibration, valuable for in-house measurements.

Request current certificates, scope statements, and audit summaries when available.

OEM Certifications and Approvals

For major OEM spindles, ask if the shop:

- Is recognized or approved by the OEM

- Uses OEM parts or equivalent components with documented specs

- Follows OEM torque, preload, and assembly procedures

If OEM certification isn’t available, ensure the shop demonstrates equivalence through procedures and test data.

Technician Training

Ensure ongoing training on:

- Precision assembly, bearing handling, and lubrication

- Electrical diagnostics for motorized spindles

- Calibration of metrology tools like laser interferometers or displacement probes

Equipment and Technology to Expect

Leading spindle repair shops invest in the right tools and metrology. Confirm the following:

Precision Balancing Machines

- Static and dynamic balancing across operating RPM ranges

- Fine resolution for ISO 21940 standards (G2.5 or better)

- Spindle-specific fixtures for accurate conditions

Grinding and Assembly Tools

- Cleanrooms or controlled clean assembly areas

- Temperature-controlled environments to avoid thermal fit errors

- Bearing heaters and calibrated preload tools

Metrology and Alignment

- Air gauges and probes for taper and bore measurements

- Dial indicators for sub-micron-level runout

- Laser alignment for shaft straightness and concentricity

Testing and Validation

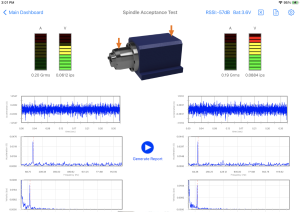

Data-backed testing ensures reliability:

- Vibration Analysis: Measures bearing defects, imbalance, or misalignment.

- Runout Testing: Confirms spindle nose and taper runout.

- Thermal Stability: Tracks growth, drift, and heat during operation.

- Load Testing: Simulates cutting forces while monitoring vibration and temperature.

- Balancing at Speed: Verifies residual vibration and accuracy under realistic conditions.

Process and Documentation

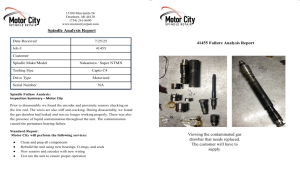

A quality shop provides detailed documentation:

- Inspection Reports: Photos, contamination findings, runout checks.

- Root-Cause Analysis: Clear failure explanations (e.g., contamination, misalignment).

- Repair Plans: Parts lists, machining steps, preload targets, and specs.

- Final Reports: Vibration plots, runout data, and thermal curves.

Clear warranties and a strong paper trail protect your investment and ensure accountability.

![]() Questions to Ask Before Committing

Questions to Ask Before Committing

- What certifications do you hold? Can you provide copies?

- Do you handle grinding, balancing, and assembly in-house?

- What are your testing and acceptance criteria for my spindle?

- Can you share sample test reports and procedures?

- How do you prevent contamination during repairs?

Red Flags to Avoid

- No clear test reports or vague “passed test” claims

- Dirty assembly areas or poor bearing handling

- Lack of calibration records

- Unrealistically low prices without explanation

Cost vs. Value: Think Total Ownership

A cheap repair that fails quickly costs more than a premium repair that lasts. Consider downtime costs, scrap rates, tooling expenses, and repeated repairs when evaluating providers.

Conclusion: Choose Quality, Demand Proof

Choosing the right spindle repair shop protects uptime, accuracy, and profitability. Look for certifications, precise equipment, and thorough testing. Insist on detailed documentation and data-backed results. By prioritizing quality and expertise, you reduce risk and ensure long-term performance.

Why Choose Motor City Spindle Repair?

When it comes to CNC spindle repairs, Motor City Spindle Repair stands out as a trusted industry leader. Our team brings years of expertise and in-depth technical knowledge to every repair, ensuring your spindle is restored to peak performance. We invest in state-of-the-art equipment and adhere to the highest standards in precision, cleanliness, and calibration. Every spindle we service undergoes rigorous testing, with transparent documentation provided for your peace of mind.

Our saying at MCSR is “If we can’t test it, we won’t rebuild it”!

Our commitment to quality extends beyond the repair itself. We prioritize fast turnaround times to keep your operations running and minimize costly downtime. Customer satisfaction is at the core of everything we do, and our proven track record and positive client feedback speak for themselves. When you choose Motor City Spindle Repair, you’re choosing a partner dedicated to your productivity and success.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE

Questions to Ask Before Committing

Questions to Ask Before Committing