How to Select the Right Spindle for Your CNC Application

Choosing the right CNC spindle is critical, as it affects your machine’s performance, part quality, and efficiency. A mismatched spindle can lead to poor finishes, reduced tool life, and machine damage.

This guide will cover everything you need to know to make an informed choice when choosing a spindle. We’ll explore key factors, spindle types, and tips for matching a spindle to your tasks, ensuring your CNC setup is optimized for success—whether you’re a beginner or a seasoned professional.

Key Factors for Choosing a CNC Spindle

Material Type

The material you machine is the most important factor, as different materials need different speeds and torque.

- Soft Materials: Woods, plastics, and foams require high speeds with lower torque for clean cuts. A high-RPM spindle works best here.

- Hard Materials: Metals like aluminum, steel, and titanium need high torque at low speeds to cut effectively and prevent tool wear.

Speed (RPM)

Spindle speed, measured in RPM, determines how fast the tool rotates and affects surface finish and tool life.

- High-Speed Spindles (24,000+ RPM): Ideal for engraving, finishing, and soft materials.

- Low-Speed Spindles (below 10,000 RPM): Best for drilling, tapping, and machining hard materials.

Power and Torque

- Power: Higher power allows for deeper cuts and faster material removal, ideal for heavy-duty production.

- Torque: Essential for cutting hard materials at low speeds. A spindle with a high RPM but low torque won’t perform well on dense materials. Always check the spindle’s torque curve.

Precision and Runout

Runout measures how much a cutting tool deviates from its center of rotation. Low runout (below 0.0005 inches) ensures precision in tasks like mold-making or engraving. High-quality bearings and balanced spindles reduce runout.

Types of Spindles and Their Uses

CNC spindles vary by cooling systems and tool-changing capabilities.

Cooling: Air-Cooled vs. Liquid-Cooled

- Air-Cooled Spindles: Affordable, simple, and great for hobbyists or light-duty work, though noisier and less efficient in heavy use.

- Liquid-Cooled Spindles: Quieter and better at dissipating heat under long or heavy loads, making them ideal for industrial applications and metal machining.

Tool Changers: Manual vs. Automatic

- Manual Tool Change (MTC) Spindles: Budget-friendly but time-consuming, requiring manual intervention to change tools.

- Automatic Tool Changer (ATC) Spindles: More expensive but significantly reduce downtime, ideal for production environments with multiple tools.

Top 5 Most Popular Spindle oems

When selecting a spindle for your CNC machine, it helps to know which OEMs (Original Equipment Manufacturers) are trusted worldwide for their quality and innovation. Here are the top five most popular CNC spindle OEMs and what sets them apart:

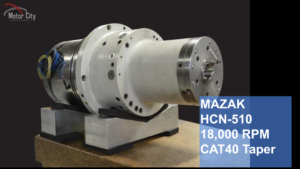

1. Mazak

2. DMG MORI

3. Haas Automation

H

4. Makino

5. Okuma

Okuma spindles are synonymous with accuracy and long-term reliability. Their unique OSP control systems are closely integrated with spindle performance, ensuring consistent quality in multi-tasking machines, vertical and horizontal centers, and grinders. Okuma is a preferred choice for manufacturers of high-value, precision components.

Conclusion: Invest in Performance!

Your spindle is the core of your CNC machine. Choosing the right spindle ensures better part quality, faster production, and long-term reliability. Carefully assess your materials, precision needs, and production goals before purchasing. Investing in the right spindle today saves you from costly upgrades and limitations tomorrow.

Why Choose MCSR for your spindle rebuilds?

Selecting the right spindle repair partner is as important as choosing the right spindle. Motor City Spindle offers unmatched expertise, fast turnaround times, and exceptional customer service.

Our technicians use advanced diagnostics and high-quality parts to restore spindles from all major brands to like-new condition, minimizing downtime and improving machine reliability. Customers praise their responsive service and transparent communication.

For reliable, high-quality repairs, trust Motor City Spindle to prioritize your uptime and satisfaction.

CONTACT US TODAY: SALES@MOTORCITYREPAIR.COM

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE

To view our most recent blog post, click HERE