Our Expert Techs are having a great Monday playing with their new Hardinge Kellenberger 100 Machine!

The Kellenberger 100 Machine is a high-performance grinder for any and all universal grinding requirements.

It specializes in Precision Grinding services for HMC/VMCs, Turning Centers, Grinding Machines, and other precision spindle applications.

The Kellenberger 100 Machine gives us the most diverse of configuration options for the widest range of grinding operations.

When components such as: spindle tapers, pilot I.D.s, front and rear bearing journals, housing bores, draw bar shafts, splines, and many other components need to be re-qualified or manufactured new, it cuts down Grind-Plate-Grind shaft rework time from 2-4 hours down to 10-20 minutes! Another critical feature is that it can rework Capto tapers. No one we know of can do this in the entire industry in our 20+ years history.

We’re running it, AND we love it so much that we’re also selling them!

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more or for your free estimate.

Motor City Spindle Repair has Precision Grinding Services:

Rework Spindle Shafts and Housings via ID/OD Grind, Chrome, Grind

Spindle Taper GPG: Cat: 30, 40, 50, 60. HSK32, 40, 50, 63, 80 100 (+ Big Plus, ISO, ANSI, KM, etc).

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

FREE door-to-door pickup services

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

- Motor City Spindle Repair has 157+ Years Experience in Our Spindle Room

- 24/7 Emergency Spindle Repair Services

- Eight Full Time Spindle Assembly Technicians

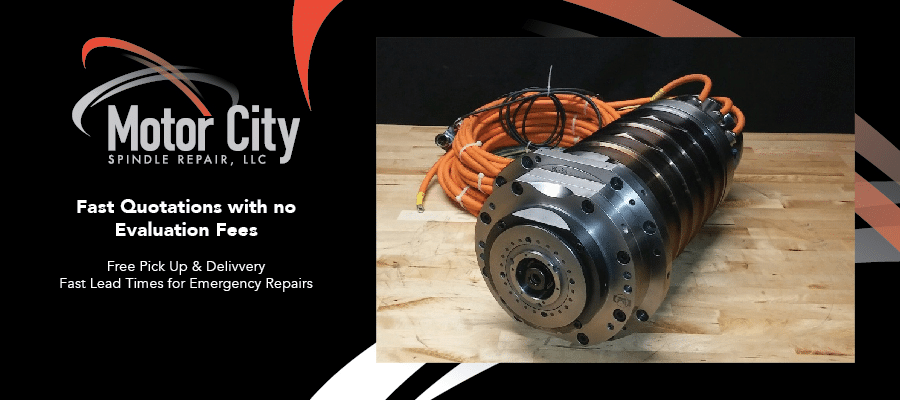

- Free Evaluations and Free Delivery Services

- All Spindles Certified and Tested with a Full 1 Year Warranty

- Free Estimates Over the Phone in Seconds

- In House Machining and Grinding Capabilities

- On-site Spindle Repair Service

- Currently performing 60-70 Spindles In House Per Month

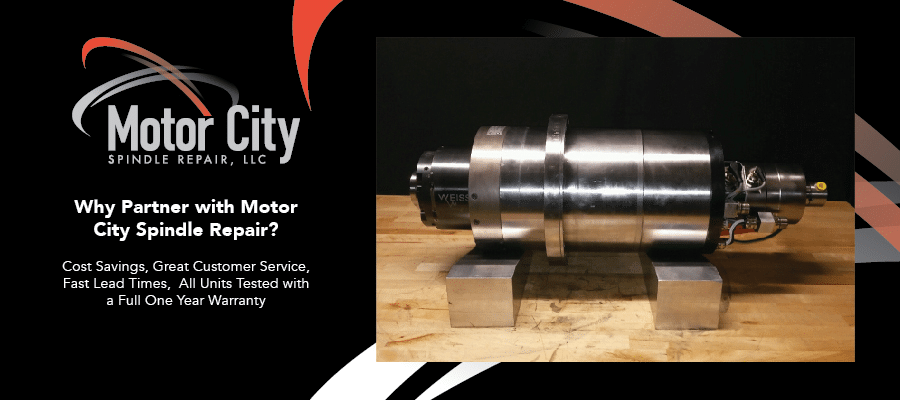

Example of a Weiss Machining Center Spindle Rebuilt in house by Motor City Spindle Repair

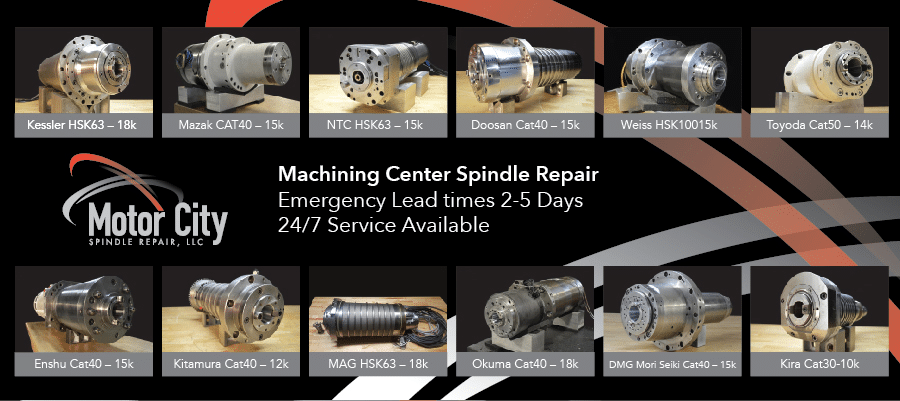

Example of a Kessler Machining Center Spindle Rebuilt in house by Motor City Spindle Repair

Example of a Mazak Machining Center Spindle Rebuilt in house by Motor City Spindle Repair

Example of an NTC Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Kessler Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Kira Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Fuji Spindle Repair Rebuilt by Motor City Spindle Repair

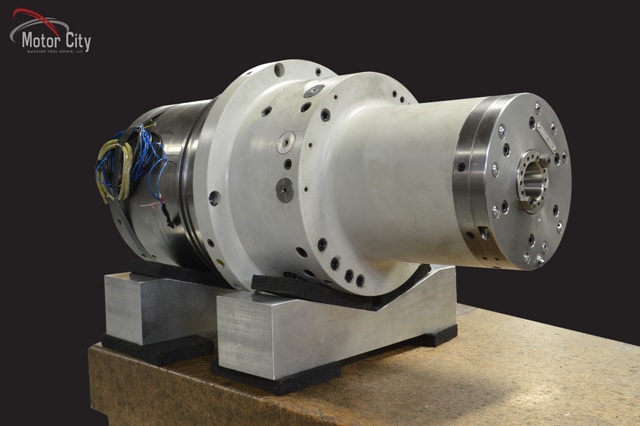

Example of Machining Center Spindle Repair Rebuilt by Motor City Spindle Repair

Example of a Kessler Machining Center Spindle In house by Motor City Spindle Repair