Measuring CNC Spindle Vibration & Balance: A Repair Guide

This guide covers how to measure and correct vibration and balance during spindle repairs, the tools needed, and step-by-step procedures for lasting results.

Why Vibration and Balance Matter

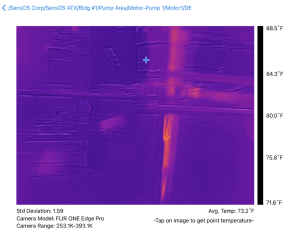

Excessive spindle vibration isn’t just annoying—it signals deeper issues and can cause future failures. It leads to poor surface finishes, reduced accuracy, and accelerated wear on bearings and cutting tools, potentially damaging spindle motors and other components.

Dynamic balance is closely tied to vibration. An imbalanced spindle rotates unevenly, creating centrifugal forces that increase vibration, especially at higher RPMs. Proper balancing minimizes these forces, resulting in smoother, more reliable operation.

Key benefits of precise vibration and balance measurement include:

- Longer Spindle Life: Balanced spindles reduce stress on bearings and internal components, extending lifespan.

- Better Part Quality: Minimal vibration keeps the cutting tool stable, ensuring superior finishes and tight tolerances.

- Higher Productivity: Reliable spindles reduce downtime, enabling optimal machining speeds and feeds.

- Lower Costs: Longer tool life and fewer failures cut maintenance and replacement expenses.

These practices are critical for all CNC machine brands, each with unique spindle requirements. Examples include:

- Haas Automation: High-speed spindles for milling/turning benefit from vibration analysis to avoid issues like poor surface finishes and bearing failures. Proper balancing ensures smoother operation for Haas VF and ST series machines.

- Mazak: Complex multi-axis machines like Integrex and Variaxis require precise balancing due to high RPMs and heavy loads. Following these steps prevents downtime and ensures tight tolerances.

- DMG Mori: Advanced spindles, including direct-drive and HSC types, demand low-vibration thresholds, especially for 5-axis milling. FFT-based vibration analysis ensures continued precision and performance.

- Okuma and Makino: High-speed spindles for aerospace and mold-making rely on vibration correction to ensure tool life and surface finish.

- Other Brands: Machines from Doosan, Kitamura, Hwacheon, and more also benefit from balanced spindles, improving accuracy, reducing breakdowns, and lowering ownership costs.

By implementing these practices, you can keep CNC machines—from Haas to Makino—performing at their best, protecting your investment and ensuring every repair meets the highest standards.

How Vibration is Measured and CNC Spindles are Balanced

Accurately assessing and correcting spindle vibration and balance requires specialized tools and a systematic approach:

Vibration Measurement Tools and Techniques

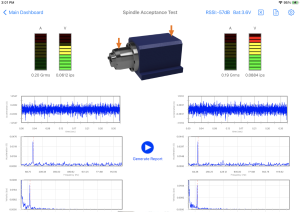

- Vibration Analyzers: These portable devices use accelerometers attached to the spindle housing to detect vibration levels across different speeds. The analyzer provides precise readings in terms of displacement, velocity, or acceleration, giving critical insight into spindle health.

- Fast Fourier Transform (FFT) Analysis: Modern vibration analyzers can perform FFT analysis, which breaks down complex vibration signals into their individual frequency components. This technique helps pinpoint whether vibration is caused by imbalance, bearing defects, misalignment, or structural resonance.

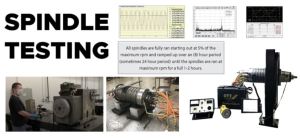

- Data Collection and Trend Monitoring: Technicians collect baseline data before repair, then compare it to post-repair results. This trend analysis is invaluable for ongoing maintenance and verifying the success of a spindle repair.

CNC Spindle Balancing Methods

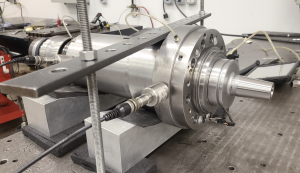

- Balancing Machines: Before full assembly, critical components like the spindle shaft are placed in a balancing machine. The machine spins the part at controlled speeds, measures imbalance, and indicates how much weight—and where—needs to be added or removed. Corrections may involve drilling material away or adding balancing weights.

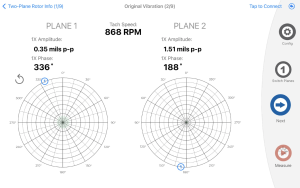

- In-Situ (On-Site) Dynamic Balancing: Once the spindle is fully assembled, in-situ balancing is used to fine-tune performance. Using a portable balancing kit (including a vibration analyzer, phase reference sensor such as a tachometer or laser, and specialized software), technicians run the spindle at operational speeds. The software determines where minor weights should be applied to the spindle assembly for final “trim balancing.”

- Precision Test Arbors and Tool Holders: For both measurement and balancing, it’s crucial to use certified, balanced arbors or tool holders. This ensures that only the spindle’s balance is evaluated, not that of the tooling.

Step-by-Step Overview

- Initial Measurement: Mount the accelerometer, run the spindle at varying speeds, and record vibration and frequency data.

- Component Balancing: During assembly, balance rotating parts individually in a balancing machine.

- Final Run-Up and Dynamic Balancing: With assembly complete, perform a controlled run-up. Monitor vibration at each speed, then use in-situ dynamic balancing tools and software to make final corrections in one or two planes as needed.

- Verification: Compare final readings to standards and machine specifications, ensuring vibration levels are within acceptable limits for the spindle and application.

These methods are essential whether servicing Haas, Mazak, DMG Mori, Okuma, Makino, or any other leading CNC machine brand. Systematic vibration measurement and dynamic balancing are critical steps in supporting optimal machine accuracy, spindle longevity, and consistent high-quality part production.

Why Choose Motor City Spindle?

At Motor City Spindle, we bring decades of experience to every spindle repair. Using advanced vibration analysis and dynamic balancing tools, we restore your spindle to peak condition with unmatched precision.

Our focus on quality means fewer breakdowns, longer spindle life, and improved performance for your operations. With thorough documentation, honest communication, and expert service, Motor City Spindle ensures reliable, high-performance spindle repairs you can trust.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE