Motor City Spindle Now Reverse Engineers Ball Screws: Precision You Can Trust in New Manufacturing

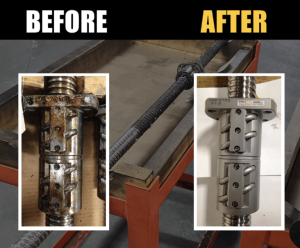

To solve this problem, Motor City Spindle now offers ball screw reverse engineering, focused specifically on producing brand-new ball screws built to exact application requirements.

This is not a repair workaround or a temporary fix. It is a controlled, engineering-driven manufacturing process designed to restore machines to reliable, long-term operation.

Why Reverse Engineering Is Critical for Ball Screws

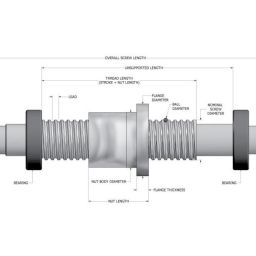

Ball screws are highly application-specific components. Even when two screws appear similar, differences in lead accuracy, preload, end machining, or internal geometry can dramatically affect machine performance. In many cases, original documentation is incomplete, OEMs no longer support the machine, or replacement lead times are simply not realistic for a production environment.

Reverse engineering removes those obstacles. By starting with the existing component and analyzing both its geometry and its function within the machine, Motor City Spindle is able to recreate a ball screw that meets the original performance intent—without relying on uncertain substitutes.

A Technical, Manufacturing-First Approach

From there, entirely new ball screws are manufactured. New screw shafts, new ball tracks, properly selected balls, and correct preload configurations are used to ensure consistent accuracy and predictable service life. The goal is not simply to “match what came out,” but to deliver a component that performs reliably under real operating conditions.

Before release, the new ball screw is verified for fit, function, and accuracy so it installs cleanly and restores the machine’s intended performance.

What This Means for Maintenance Managers

For maintenance and reliability teams, reverse engineering ball screws offers a practical and dependable alternative to OEM-only sourcing. It reduces exposure to long lead times, eliminates uncertainty around discontinued components, and provides confidence that the replacement is truly new—not a reused or compromised assembly.

Just as importantly, it creates a documented solution. Once a ball screw has been reverse engineered, future replacements can be produced without starting from scratch, giving maintenance teams greater control over planning, spares strategy, and downtime risk.

Built for Long-Term Reliability, Not Short-Term Fixes

Motor City Spindle’s reverse engineering capability is designed for facilities that value precision, uptime, and repeatability. By manufacturing new ball screws based on verified engineering data, we help extend machine life, stabilize process capability, and protect part quality across production runs.

When your operation depends on accuracy and consistency, trusting your ball screws to a proven, engineering-focused process makes all the difference.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE