New Year, New Spindle Strategy: How to Start the Year With Reliable CNC Performance

The spindle is the heart of your CNC machine. When it underperforms or fails, accuracy suffers, scrap increases, and production comes to a halt. Starting the year with a proactive spindle strategy can help ensure consistent performance, longer spindle life, and fewer surprises throughout the year.

Why the New Year Is the Ideal Time to Focus on CNC Spindle Health

The beginning of the year provides a natural opportunity to assess equipment condition before production ramps up. Addressing spindle issues early helps avoid failures during peak demand and allows maintenance teams to plan repairs rather than react to emergencies.

Many spindle problems start small—slight vibration, unusual noise, heat buildup, or declining surface finish. If ignored, these early warning signs can lead to catastrophic failure, extended downtime, and significantly higher repair costs.

Step One: Schedule a Professional Spindle Health Assessment

A successful spindle strategy starts with understanding the current condition of your equipment. A professional spindle inspection evaluates critical factors such as:

-

Bearing condition and wear

-

Runout and vibration levels

-

Balance and alignment

-

Lubrication system performance

-

Thermal behavior under load

At Motor City Spindle Repair, thorough inspections help identify problems early—often before operators even notice a change in performance—allowing shops to plan service on their terms.

Preventive Maintenance vs. Reactive Spindle Repair![]()

Reactive spindle repairs often come at the worst possible time: missed deadlines, rushed turnaround, and unexpected costs. Preventive maintenance, on the other hand, helps extend spindle life and maintain machining accuracy.

Proactively rebuilding or servicing a spindle before failure can reduce total cost of ownership, improve part quality, and minimize disruptions to production schedules. Shops that plan spindle maintenance typically experience fewer emergencies and more predictable operating costs throughout the year.

Why Spindle Testing and Balancing Matter

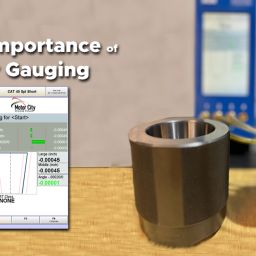

Repair alone isn’t enough—verification is critical. Proper dynamic balancing, run-in procedures, and performance testing ensure a spindle returns to service meeting or exceeding OEM specifications.

Without comprehensive testing, even a newly repaired spindle can introduce vibration, shorten bearing life, and negatively impact surface finish. Motor City Spindle Repair prioritizes testing and balancing to ensure long-term reliability—not just a quick fix.

Planning Ahead to Minimize CNC Downtime

The most reliable CNC operations schedule spindle service during planned downtime or slower production

periods. Building a relationship with a dedicated spindle repair partner allows for faster turnaround times, consistent repair quality, and expert support when it matters most.

A proactive spindle strategy turns maintenance from a disruption into a competitive advantage.

Start the Year Strong With Motor City Spindle Repair

A new year is the perfect time to protect your CNC investment. By prioritizing spindle health, addressing issues early, and choosing preventive maintenance over reactive repair, your shop can improve reliability and hit production goals with confidence.

Reliable machines start with reliable spindles—and reliable spindles start with a plan.

👉 Contact Motor City Spindle Repair today for a spindle inspection or free repair quote and start the year with confidence.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE