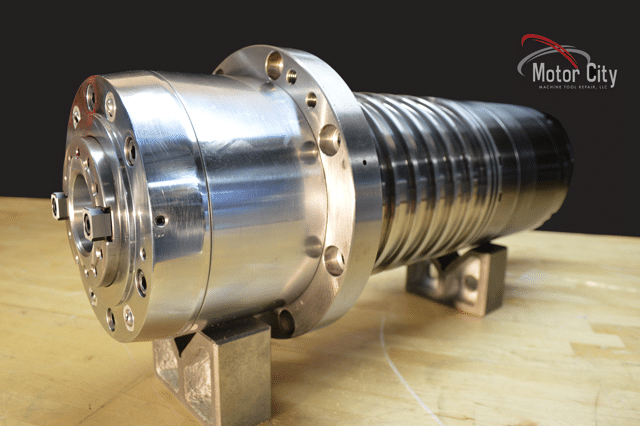

Motor City Spindle Repair received this NTC Spindle, which was locked up. Once The N400H Spindle was disassembled and inspected, our technician found that one of the front bearings was badly damaged, such that the cage had broken, while others were burnt. We suspect this was caused by coolant contamination, which washed out the lubricant from the bearings. To prevent this from happening in the future, all seals and o-rings were replaced with new ones. There damage done to the drawbar nut and the threading for the nut, which was replaced, and the drawbar threading was repaired. In addition, components such as a sensor and coil springs were replaced to ensure the proper operation of the spindle in future use. The Spindle Taper had some wear to it, which was reworked back to the HSK 63 specifications. Once all new and reworked components were received by Motor City Repair, one of our Experienced Spindle Technicians Reassembled the with brand new Ceramic Ball Bearings, Which perform well under the higher speeds that this spindle operates at. Once the Spindle was reassembled, it was test run on our Test Stand for four(4) hours at maximum RPMs, and was precisely balanced by one of our Skilled Spindle Technicians. We are confident that this spindle will run precisely for a long time to come, given the proper operation and maintenance.

Give us a call at (734) 261-8600 to find out why Motor City Spindle Repair is one of the fastest growing cnc spindle repair companies in the USA. Check us out at www.motorcityrepair.com