Why Q1 Is the Best Time to Inspect and Rebuild Your CNC Spindles

The first quarter of the year is more than just a fresh start—it’s a strategic opportunity for manufacturers to strengthen equipment reliability before production demands peak. One of the smartest moves a shop can make during Q1 is inspecting and rebuilding CNC spindles before problems turn into costly downtime.

CNC spindles are the heart of your machine. When they fail, accuracy, productivity, and deadlines suffer. Addressing spindle health early in the year helps ensure smoother operations, better planning, and fewer emergencies down the road.

Lower Production Pressure Makes Planning Easier

For many shops, Q1 brings slightly lighter production schedules compared to mid-year or end-of-year rushes. This makes it an ideal time to schedule inspections or rebuilds without disrupting delivery commitments.

Waiting until a spindle fails often forces shops into reactive decisions—expedited repairs, rushed shipping, and extended downtime. Q1 allows you to plan service on your terms instead of reacting under pressure.

Catch Small Issues Before They Become Big Problems

Most spindle failures don’t happen suddenly. They develop over time through bearing wear, imbalance, lubrication issues, or thermal stress. Early warning signs—such as vibration, noise, or declining surface finish—can often go unnoticed during busy production periods.

A professional spindle inspection in Q1 can identify these issues early, allowing for corrective action before they escalate into catastrophic failure. Preventive rebuilds are almost always more cost-effective than emergency repairs.

Improve Accuracy and Part Quality Early in the Year

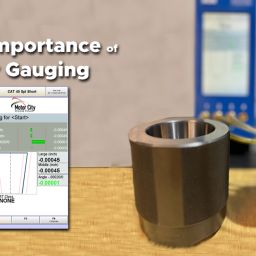

Worn or imbalanced spindles directly impact machining accuracy, surface finish, and tool life. Starting the year with properly inspected and rebuilt spindles helps ensure consistent performance across all jobs.

Better spindle health means fewer scrapped parts, longer tool life, and tighter tolerances—benefits that compound throughout the year and positively affect your bottom line.

Reduce the Risk of Unplanned Downtime

Unplanned downtime is one of the most expensive issues in manufacturing. Emergency spindle failures can halt production for days or even weeks, especially if replacement parts or expedited services are required.

By addressing spindle condition in Q1, shops significantly reduce the likelihood of unexpected breakdowns during peak production periods. Planned maintenance is always less disruptive than emergency repair.

Budget Smarter for the Year Ahead

Q1 inspections and rebuilds also support better budgeting. Knowing the condition of your spindles early in the year allows you to forecast maintenance costs instead of absorbing unexpected expenses later.

Shops that plan spindle service upfront often experience fewer surprises and more predictable operating costs throughout the year.

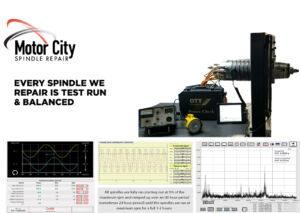

The Importance of Professional Testing and Balancing

A proper spindle rebuild is only as good as the testing that follows it. Dynamic balancing, run-in procedures, vibration analysis, and performance verification are essential to ensure the spindle meets or exceeds OEM specifications.

At Motor City Spindle Repair, every rebuild includes thorough testing and balancing to ensure long-term reliability—not just short-term fixes.

Start the Year Strong With Motor City Spindle Repair

Q1 is the best time to invest in spindle health, protect production schedules, and reduce downtime before it becomes a problem. Whether your spindles need a simple inspection or a full rebuild, addressing them early sets your shop up for a smoother, more productive year.

Don’t wait for failure to force your hand—plan ahead and keep your machines running at their best.

👉 Contact Motor City Spindle Repair today to schedule a spindle inspection or request a free repair quote.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE