Our state of the art repair facility allows us to repair today’s most complicated Grinding spindles. We repair Grinding spindles of all types, including surface grinders, cylindrical grinders & Centerless Grinders. We have state of the art equipment that allows our spindle technicians to very precisely balance all spindles that are repaired by us.

Grinding spindles can be used for rough shop bench grinding to highly precise CNC machining applications. CNC grinders are used for working materials such as: metal, plastic, stone, wood, glass and composites. Motor City Spindle Repair specializes in grinding spindle repair. We are confident we can repair your grinding spindle from any machine.

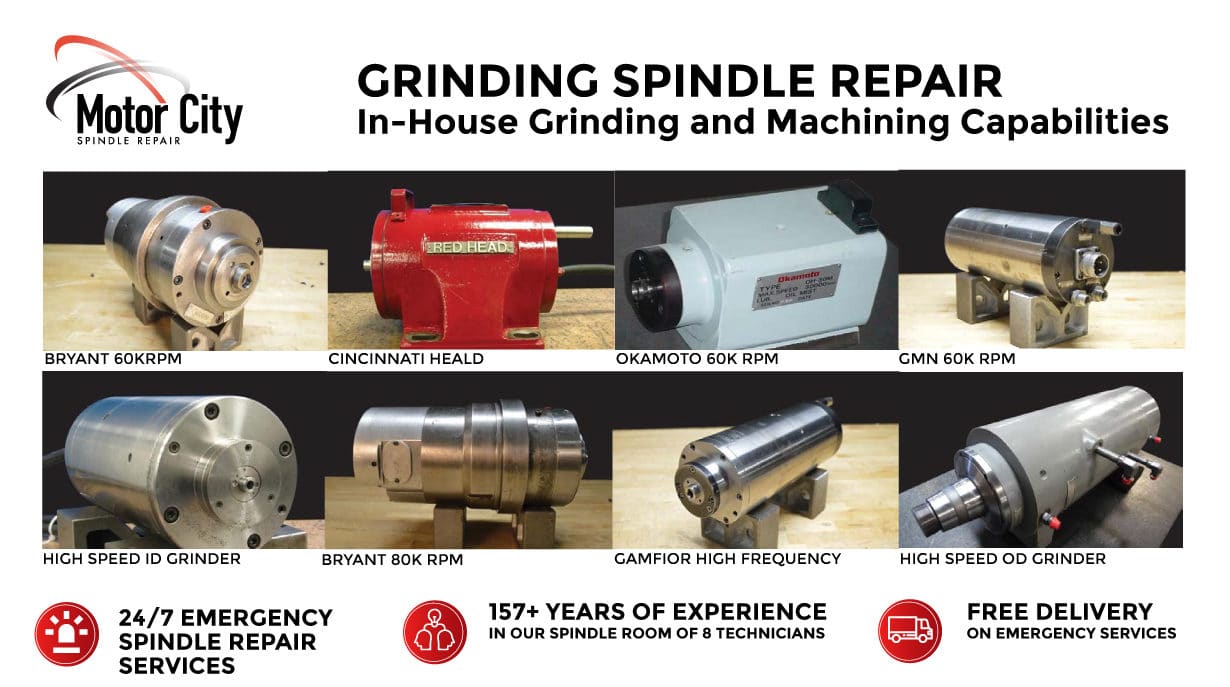

Motor City Spindle Repair specializes in high speed grinding spindle repair services. While some repair facilities are incapable of repairing or testing high speed grinding spindles, we are able to do both for spindles that run as fast as 150,000 RPM. Our advanced equipment and experienced staff of spindle technicians are more than qualified to repair any high speed spindle sent to us.

Often times the extremely fast running spindles will be Hydrodynamic or Hydrostatic Spindles, because they operate with frictionless fluid bearings that don’t produce the excessive heat and vibration that steel or ceramic bearings would if they were ran at such high speeds. These fluid bearings are extremely efficient, but can fail due to contaminated oil or damaged seals. Our spindle technicians are quite familiar with these issues and know how to properly get a hydrostatic or hydrodynamic spindle to run to the OEM specifications.

We understand the importance of decreasing machine down time so we stock precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts. Our Four Spindle Test Stands are all equipped with variable frequency drives to allow us to rebuild, test run and ship multiple spindles daily.

Give us a call at (734) 261-8600 or email us at Sales@motorcityrepair.com

– A Hardworking staff of trained professionals.

– An Efficient System of Repair, built with years of industry experience.

– In house Machining & Grinding capabilities.

– Stock parts for a faster turn around, such as precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts.

Our state of the art repair facility allows us to repair today’s most complicated Grinding spindles. We repair Grinding spindles of all types, including surface grinders, cylindrical grinders & Centerless Grinders. We have state of the art equipment that allows our spindle technicians to very precisely balance all spindles that are repaired by us.

Grinding spindles can be used for rough shop bench grinding to highly precise CNC machining applications. CNC grinders are used for working materials such as: metal, plastic, stone, wood, glass and composites. Motor City Spindle Repair specializes in grinding spindle repair. We are confident we can repair your grinding spindle from any machine.

Motor City Spindle Repair specializes in high speed grinding spindle repair services. While some repair facilities are incapable of repairing or testing high speed grinding spindles, we are able to do both for spindles that run as fast as 150,000 RPM. Our advanced equipment and experienced staff of spindle technicians are more than qualified to repair any high speed spindle sent to us.

Often times the extremely fast running spindles will be Hydrodynamic or Hydrostatic Spindles, because they operate with frictionless fluid bearings that don’t produce the excessive heat and vibration that steel or ceramic bearings would if they were ran at such high speeds. These fluid bearings are extremely efficient, but can fail due to contaminated oil or damaged seals. Our spindle technicians are quite familiar with these issues and know how to properly get a hydrostatic or hydrodynamic spindle to run to the OEM specifications.

We understand the importance of decreasing machine down time so we stock precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts. Our Four Spindle Test Stands are all equipped with variable frequency drives to allow us to rebuild, test run and ship multiple spindles daily.

Give us a call at (734) 261-8600 or email us at Sales@motorcityrepair.com

– A Hardworking staff of trained professionals.

– An Efficient System of Repair, built with years of industry experience.

– In house Machining & Grinding capabilities.

– Stock parts for a faster turn around, such as precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair