Spindles Tested & Approved by Major OEMs

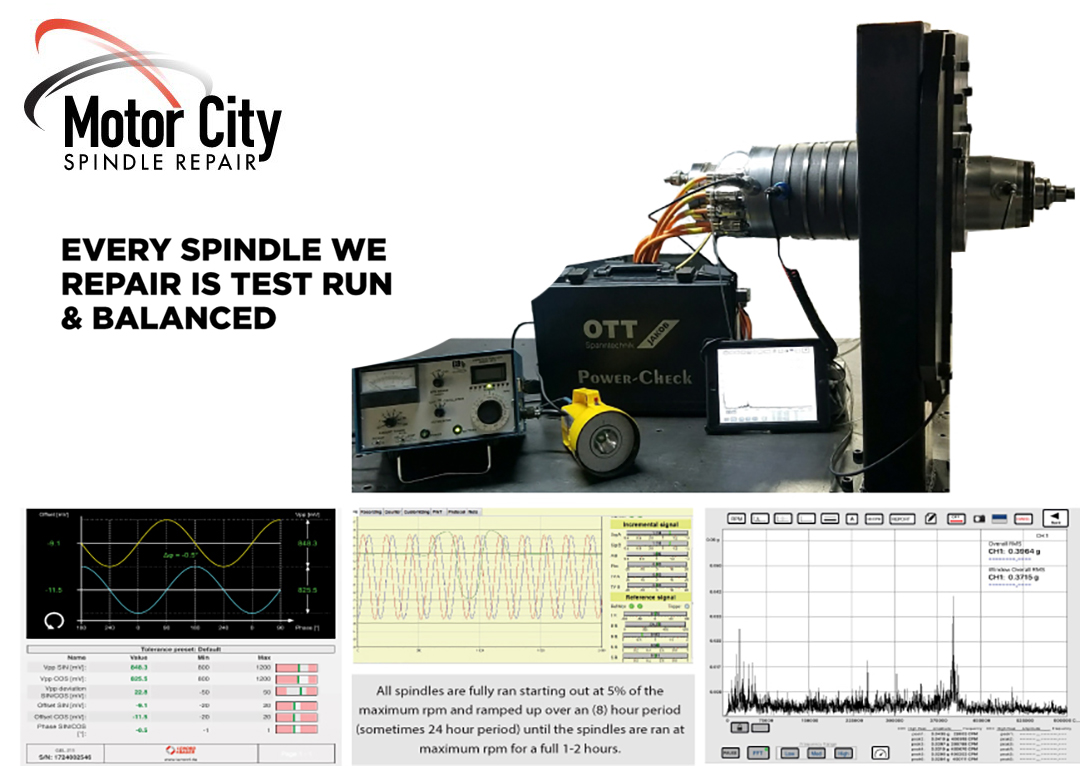

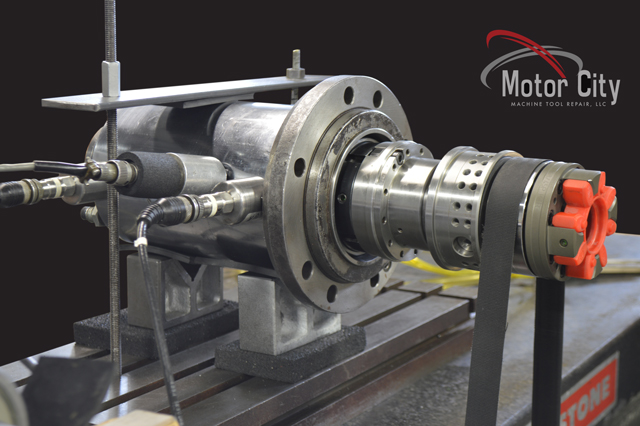

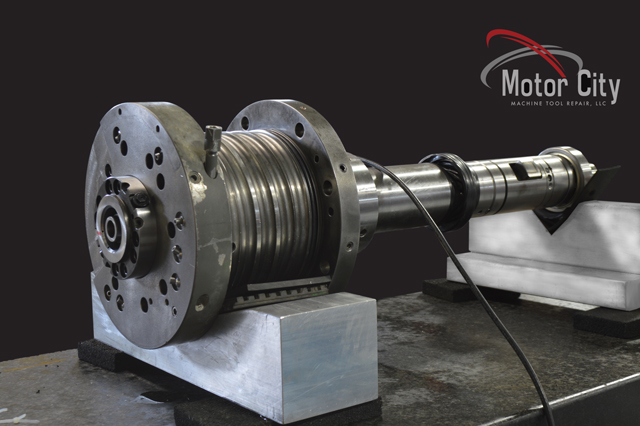

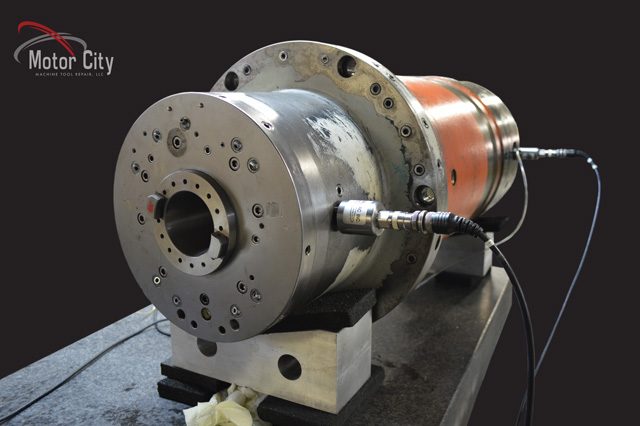

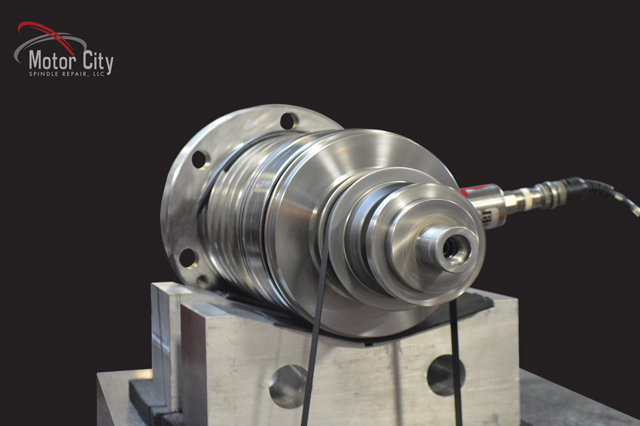

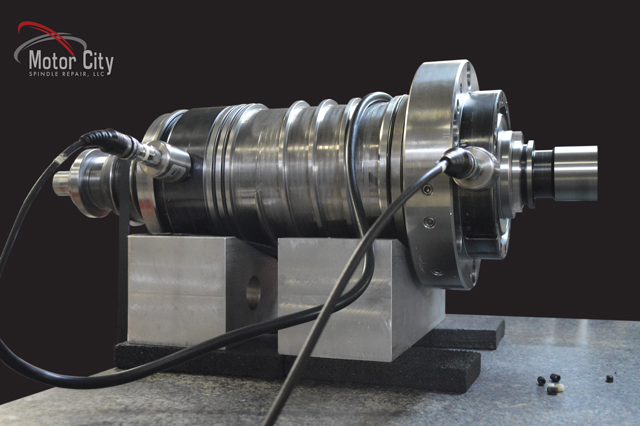

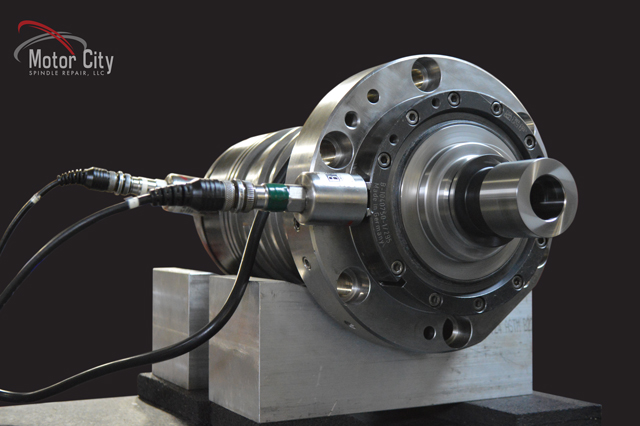

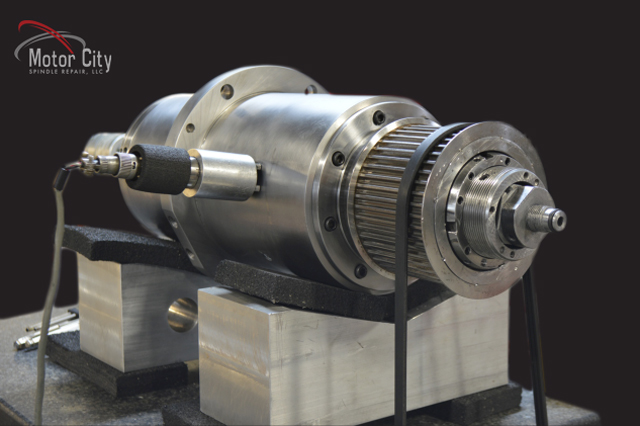

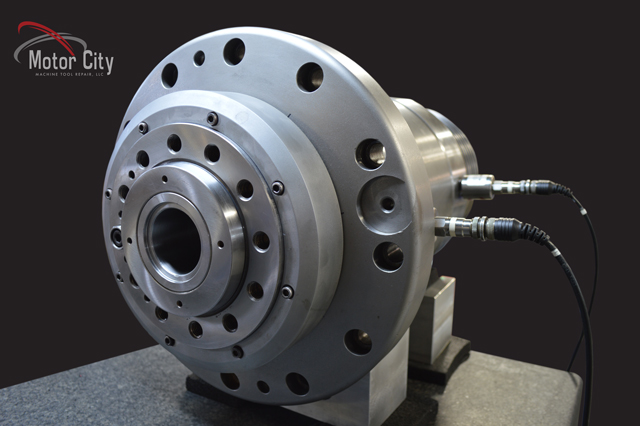

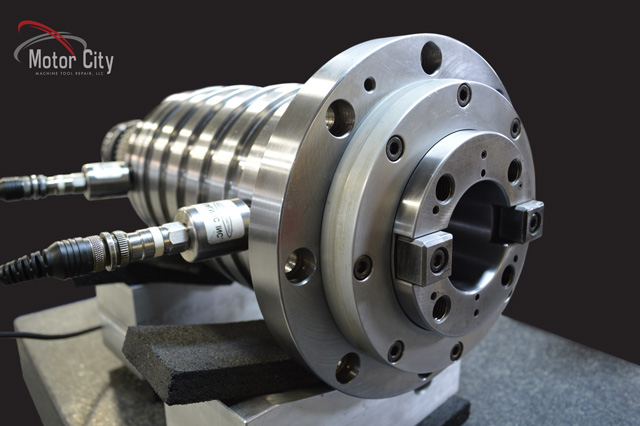

Motor City Spindle Repair Test Runs every cnc spindle we repair for our customers and many of our customers are Major CNC OEMs and Distributors. Our in house Spindle Testing Department simulates how a spindle operates in the cnc machine tool.

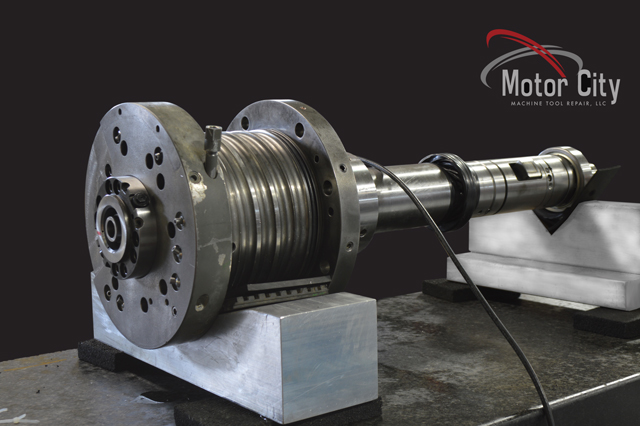

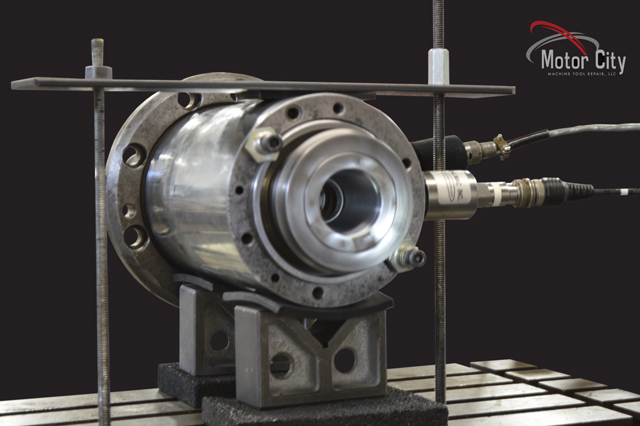

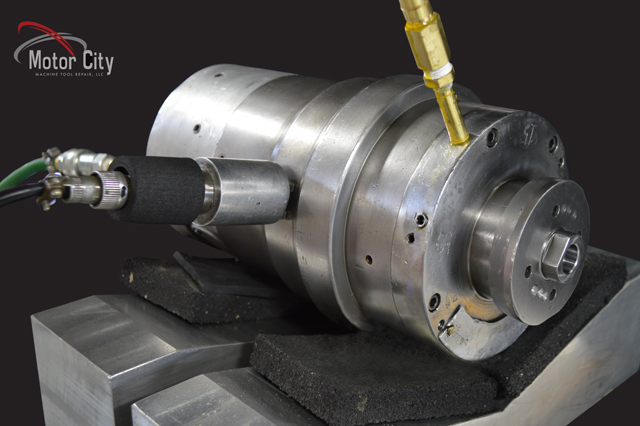

SPINDLE TESTING

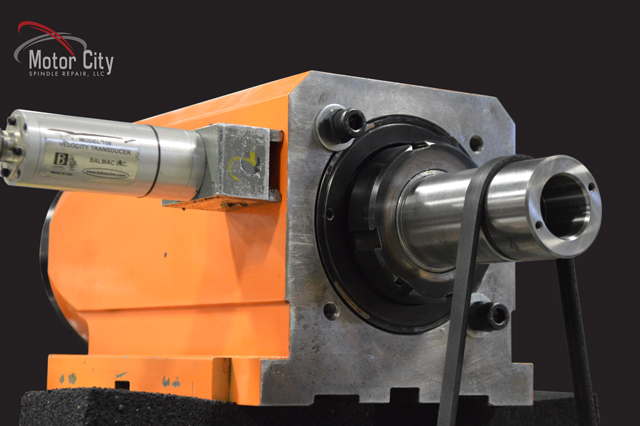

- Vibration Analysis

- Spindles Ran to Maximum Rpm

- Velocity (Measured and Documented with Video)

- Acceleration (Measured and Documented with Video)

- Displacement (Measured and Documented with Video)

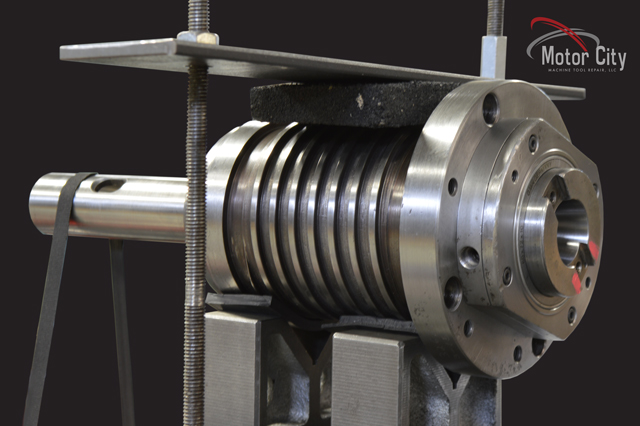

- Dynamically Balanced

- Trim Balanced

- Draw Bars

- Encoders

- Thermistors

- Motor Windings

SIX DEDICATED SPINDLE TEST STANDS for:

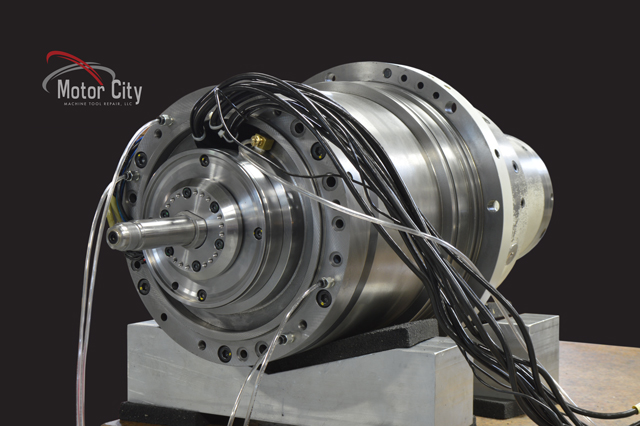

- Motorized Spindles

- Machining Center Spindles

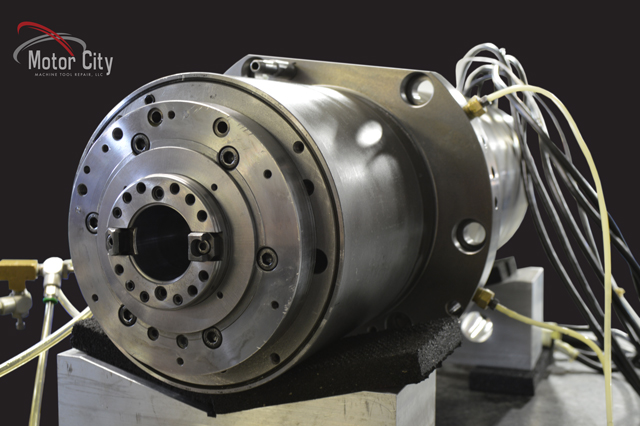

- Turning Center Spindles

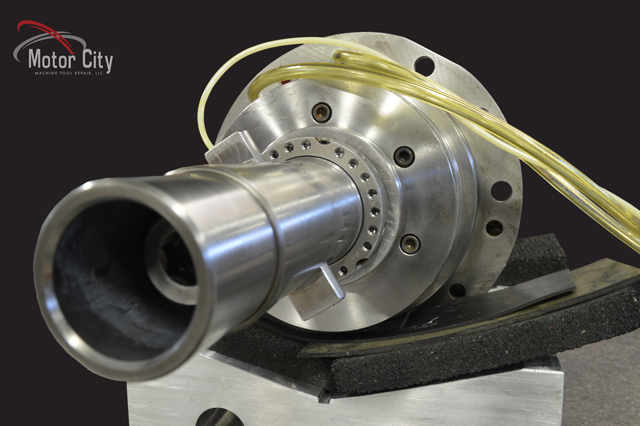

- Cartridge Spindles

- Belt Driven Spindles

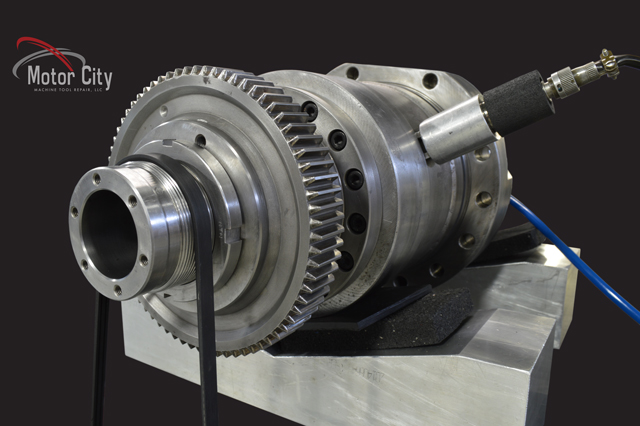

- Gear Driven Spindles

- High Frequency Spindles (up to 150,000 rpm)

- Oil Mist Lubricated Spindles

- Oil Chilled Spindles

Our success is visible by our continuous growth year after year even during Covid19. That is why many of the world’s largest CNC Machine Tool OEMs trust the Motor City Spindle Repair Team.

If you are interested in touring our 25,000 sq.ft spindle remanufacturing to see all our departments first hand our doors are always open to the public.

Motor City Spindle Repair Department

- Spindle Room (5000 sq.ft)

- Machine Shop / Grinding Dept. (4500 sq.ft)

- Tear Down / Inspection (5000 sq.ft)

- Spindle Testing Dept (2500 sq.ft)

Thank you and we look forward to learning more about the cnc machine tools you operate and how we can keep you running.

Spindle Testing is critical to ensure the highest quality is shipped by our Team.

That is why our motto is:“If we can’t test it we won’t rebuild it”– Brian Burns

Owner

Euroma Spindle Testing

Chiron Spindle Testing

Johnford Spindle Testing

Toyoda Spindle Testing

Mazak Spindle Testing

Bridgeport Spindle Testing

Bridgeport Spindle Testing

Bridgeport Spindle Testing

Daewoo Spindle Testing

Hyundai Wia – Turning Spindle Testing

Johnford Spindle Testing

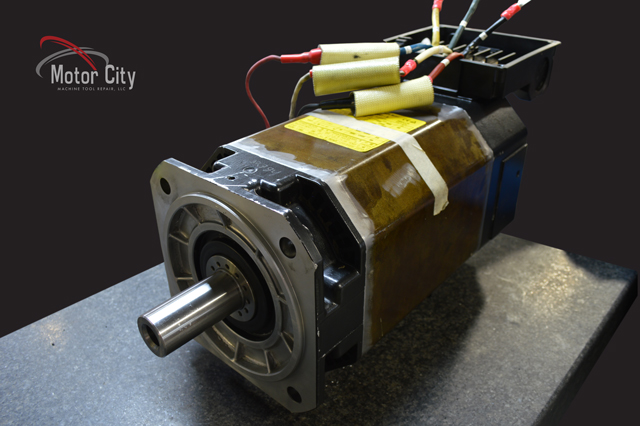

Fanuc Spindle Testing

Toyoda Spindle Testing

Chiron Spindle Testing

High Speed Spindle Testing

Motorized Spindle Testing

CNC Spindle Testing

CNC Spindle Testing

CNC Spindle Testing

MAJOR OEMS WE WORK WITH:

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series