The Hidden Cost of OEM Lead Times on CNC Spindle Failures

When a CNC spindle fails, downtime is expected—but what many shops underestimate is how expensive OEM lead times truly are. While the upfront price of an OEM replacement spindle is easy to see, the real cost is hidden in weeks or even months of lost production, disrupted schedules, and mounting operational pressure.

OEM lead times don’t simply delay repairs. They multiply downtime and quietly erode profitability in ways that are often only realized after the damage is done.

What OEM Lead Times Really Mean for Shops

During this waiting period, shops are forced to operate around a critical gap in their workflow, often without clear visibility into when production will resume.

The True Cost of Waiting on an OEM Spindle

Every day a machine sits idle represents lost production hours that can never be recovered. Missed deliveries, delayed jobs, and reduced output quickly outweigh the cost difference between repair and replacement. Labor inefficiencies follow closely behind, as operators and maintenance teams are reassigned, underutilized, or forced into last-minute schedule changes.

To keep commitments, many shops turn to overtime, outsourcing, or expedited processes elsewhere in the facility. These short-term fixes introduce additional costs and strain resources, all while customer relationships are tested by extended downtime and uncertainty.

OEM lead times don’t just affect one machine—they ripple across the entire operation.

Repair as a Strategic Alternative

The difference lies in choosing a repair facility with the technical knowledge, in-house capabilities, and quality controls necessary to rebuild spindles correctly—not just quickly.

Planning Ahead Changes Everything

Shops that avoid emergency-level downtime are rarely reacting—they are planning. Evaluating repair options before failure, keeping spare spindles available, and scheduling rebuilds during planned downtime transforms spindle failure from a crisis into a controlled maintenance event.

Proactive strategies reduce stress on teams, protect production schedules, and ultimately save significant time and money.

Why Shops Trust Motor City Spindle Repair

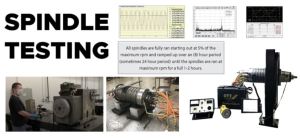

At Motor City Spindle Repair, we understand that time is just as critical as precision. Our team focuses on reducing downtime through efficient spindle rebuilds, comprehensive testing, and clear communication from quote to completion.

With experienced technicians, in-house capabilities, and a one-year in-service warranty that begins when the spindle is installed—not when it ships—we help sh

When spindle failure happens, you don’t have to choose between speed and quality. With Motor City Spindle Repair, you get both.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE