Thermal Stability in CNC Spindles: Why It Matters and How to Manage It

This post explains why thermal stability is essential and offers practical strategies to manage it. Learn how heat impacts your spindle, the risks of ignoring it, and how to maintain accuracy for high-quality results.

What is Thermal Stability in a CNC Spindle?

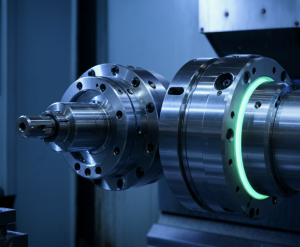

Thermal stability is a spindle’s ability to maintain a consistent temperature under varying loads and speeds. As spindles generate heat, components like bearings and gears expand. Even minor thermal growth can shift the tool’s position, causing inaccuracies. A thermally stable spindle minimizes this expansion for consistent precision.

Why Thermal Stability is Critical

Thermal stability plays a vital role in precision machining. Here’s why:

1. Ensures Dimensional Accuracy

Heat-induced expansion can alter tool positions, especially along the Z-axis, resulting in off-spec parts. This is critical in industries like aerospace and medical manufacturing. A stable spindle prevents these deviations, ensuring uniform production.

2. Improves Surface Finish

Temperature fluctuations cause vibrations and runout, leading to poor surface finishes. Stability eliminates these issues, producing smoother results and reducing extra finishing work.

3. Extends Spindle and Tool Life

Excessive heat degrades bearings and tool holding, increasing wear and risk of failure. Thermal stability reduces strain, prolonging spindle and tool life.

4. Reduces Downtime

Thermal drift often requires manual offsets, wasting time and resources. Managing spindle temperature ensures reliable processes, minimizing downtime and maximizing efficiency.

How to Manage Spindle Thermal Stability

Maintaining thermal stability involves smart practices, regular maintenance, and advanced technology:

1. Warm-Up Cycles

Run a warm-up program at the start of each shift to gradually bring the spindle to operating temperature, ensuring uniform expansion.

2. Cooling Systems

Modern spindles feature systems like liquid cooling jackets or air/oil lubrication to manage heat during operations. Regularly check coolant levels, clean radiators, and maintain systems.

3. Temperature Monitoring

Monitor spindle temperature in real-time to detect spikes. Advanced systems automatically compensate for thermal expansion, maintaining accuracy.

4. Regular Maintenance

Lubricate bearings properly, clean tool holders, and balance pull studs. Preventative maintenance reduces heat generation and vibration.

Top Machine Tool Brands and Thermal Stability

Leading CNC manufacturers integrate thermal control into their designs to ensure accuracy. Here’s how top brands address stability challenges:

- DMG Mori: Uses temperature-compensated structures and active cooling for high-speed machining.

- Mazak: Implements SMOOTH Technology to monitor and respond to temperature changes.

- Makino: Features advanced cooling channels and sensors for consistent precision.

- Okuma: Industry-leading thermal compensation ensures accuracy in fluctuating shop conditions.

- Haas: Equips machines with effective cooling and temperature monitoring for accessible thermal stability.

Choosing a brand with robust thermal control enhances accuracy, repeatability, and tool life.

![]() Why Choose Motor City Spindle repair?

Why Choose Motor City Spindle repair?

Thermal stability isn’t just about having a quality spindle—it’s about partnering with a repair specialist who truly understands the challenges of CNC machining. Motor City Spindle stands out as a trusted leader in spindle repair, offering a comprehensive range of services designed to keep your machines running at peak accuracy and efficiency.

Expertise and Services:

Our team combines decades of experience with state-of-the-art diagnostic equipment, enabling them to diagnose, repair, and rebuild all major spindle brands and styles—including high-speed, high-frequency, and motorized spindles. Our service menu covers full spindle rebuilds, failure analysis, vibration analysis, dynamic balancing, taper restoration, and in-house precision grinding. Preventative maintenance programs and emergency repair options help minimize your downtime and avoid costly disruptions.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE

To view our most recent blog post, click HERE

Why Choose Motor City Spindle repair?

Why Choose Motor City Spindle repair?