Top 5 Mistakes That Destroy Spindles Early

This guide covers the top five mistakes that can ruin a spindle prematurely. By recognizing these issues and adopting better practices, you can extend equipment life, boost performance, and reduce costs.

1. Improper Tooling and Unbalanced Holders

Using improper or poorly maintained tooling is a common cause of spindle failure. An unbalanced tool holder spinning at high speeds creates vibrations that damage spindle bearings over time, leading to noise, poor finishes, and eventual failure.

Tips to Avoid This:

- Invest in Quality Holders: Use high-quality, balanced tool holders rated for your spindle’s RPM.

- Inspect Tooling Regularly: Check for wear or damage before use to avoid imbalance.

- Balance Assemblies: For high-speed operations, professionally balance your entire tool assembly (holder, collet, nut, and tool).

- Use the Right Collet: Ensure the collet matches the tool shank size for proper clamping.

2. Ignoring Lubrication and Contamination

Lubrication is critical for spindle bearings. Too little causes overheating and seizing, while too much creates excess heat and pressure. Contamination from coolant, chips, or dust can also turn lubricant into an abrasive slurry that damages bearings.

Tips to Avoid This:

- Follow the Manufacturer’s Schedule: Use only the recommended lubricant type and adhere to the schedule.

- Keep It Clean: Wipe down the spindle taper and tooling before every tool change to prevent debris from entering.

- Check Air Supply: Maintain clean, dry air for oil-air or oil-mist systems by using filters and dryers.

- Inspect Seals: Regularly check spindle seals for wear or damage.

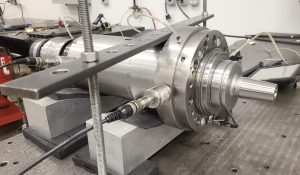

3. Poor Operating Practices and Crashes![Backup Spindle Storage]()

Operator errors, such as crashes or pushing machines beyond their limits, can cause immediate damage. Even small collisions can dent bearings, crack ceramic balls, or bend the spindle shaft, leading to long-term failure.

Tips to Avoid This:

- Train Operators Thoroughly: Ensure operators know the machine’s limits and proper speeds/feeds.

- Use Machine Features: Tools like “dry run” and “graphics mode” can help avoid collisions.

- Inspect After Impacts: After any crash, check spindle runout with a test bar or have it inspected by a technician.

4. Skipping Warm-Up and Cool-Down Cycles

Spindles need gradual warm-up and cool-down cycles to prevent damage. Starting a cold spindle at high speeds or abruptly stopping it after extended use can cause thermal distortion and bearing damage.

Tips to Avoid This:

- Warm-Up Program: Run a warm-up cycle at the start of each shift or after long idle periods to distribute lubricant evenly.

- Cool-Down Cycle: Let the spindle run at low RPM for a few minutes before shutdown to nor

malize temperatures.

- Automate It: Use CNC controls to automate these processes.

5. Mishandling Spindles and Tools

Improper handling during transport, installation, or tool changes can damage the precision components of a spindle. Using force, such as a hammer, to free stuck tools can send shock loads into the bearings, causing permanent damage.

Tips to Avoid This:

- Handle with Care: Use proper lifting equipment and follow installation instructions carefully.

- Avoid Hammers: Investigate stuck tools instead of forcing them loose. Clean tapers regularly to prevent fretting corrosion.

Protect Your Spindle

Need Help? Contact Motor City Spindle Repair

Contact us today for a free, no-obligation quote. Let us help keep your machines and your business running at their best!

sales@motorcityrepair.com

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE

malize temperatures.

malize temperatures.