Understanding CNC Spindle Tapers: CAT, BT, HSK, ISO, and Capto

This guide covers the most common spindle tapers—CAT, BT, HSK, ISO, and Capto. We’ll explore their design, applications, pros, and cons to help you decide which suits your needs.

The Role of the Spindle Taper

The spindle taper’s job is to create a strong, precise, and repeatable connection. It must securely clamp the tool holder, transfer torque without slipping, and stay concentric at high speeds. A weak connection can lead to issues like tool runout, vibration, poor surface finishes, and reduced tool life. Here’s a breakdown of the major taper types:

1. CAT (Caterpillar) Taper

Commonly called the V-Fla

- Design: Features a single V-shaped flange for the automatic tool changer (ATC) to grip. Uses imperial threads for the retention knob.

- Applications: Ideal for milling, drilling, and tapping at low to moderate speeds. Popular in U.S. job shops and manufacturing.

- Advantages:

-

- Availability: Affordable and widely used.

- Simplicity: Reliable for standard applications.

- Interchangeability: CAT40 and BT40 can sometimes share spindles (with different pull studs).

- Disadvantages:

-

- Speed Limitations: Above 8,000-10,000 RPM, thermal expansion can loosen the taper, causing tool runout.

- Imbalance: The single flange and retention knob can create vibration at high speeds.

2. BT (Bottle Taper) Taper

- Design: Features a thicker, symmetrical flange for better balance. Uses metric threads for the retention knob.

- Applications: Similar to CAT but better suited for moderate to high-speed machining due to improved balance.

- Advantages:

-

- Improved Balance: Reduces vibration, improving surface finish and tool life.

- Global Standard: Widely used in Asia and Europe.

- Disadvantages:

-

- Speed Limitations: Still affected by thermal expansion at high speeds.

- Retention Knob Differences: The metric pull stud is not interchangeable with CAT’s imperial version.

3. HSK (Hohlschaftkegel) Taper

HSK, or “hollow shank taper,” was developed in the 1990s to handle high-speed machining. It deviates from the 7:24 ratio with a shorter, 1:10 taper.

- Design: Combines taper and face contact. Thehollow shank expands via internal clamps, creating a rigid and balanced connection that strengthens with centrifugal force.

- Applications: Ideal for high-speed, high-precision machining in aerospace, mold-making, and medical industries.

- Advantages:

-

- High-Speed Performance: Face contact prevents z-axis variation at high speeds, maintaining accuracy and stability.

- Rigidity: Dual-contact design allows aggressive cutting and better finishes.

- Repeatability: Exceptional tool change accuracy for tight tolerances.

- Disadvantages:

-

- Higher Cost: More expensive than CAT or BT systems.

- Contamination Sensitivity: The face contact surface must remain clean to avoid runout or damage.

4. ISO Taper

- Design: Similar to CAT but with slightly different flange dimensions. Not interchangeable with CAT or BT holders.

- Applications: Suitable for general-purpose machining on older equipment.

- Advantages:

-

- Reliable for Basics: Works for low-speed, general machining.

- Disadvantages:

-

- Obsolete: Mostly replaced by BT and CAT, making tooling harder to find.

- Same Limitations: Struggles with high-speed performance like other 7:24 systems.

5. Capto (Coromant Capto) Taper

Developed by Sandvik Coromant, Capto features a tapered polygon shape and is standardized as ISO 26623. It’s designed for turning, milling, and drilling.

- Design: A polygonal taper with face contact for extreme rigidity and torque transfer. Modular design allows use across different machines and operations.

- Applications: Used in multi-task machines and for both static and rotating applications.

- Advantages:

-

- High Torque: Polygon design prevents rotation and excels at heavy cutting.

- Versatility: One system supports multiple machines and operations.

- Accuracy: Dual-contact design ensures stability and precision.

- Disadvantages:

-

- Cost: The most expensive option.

- Proprietary Nature: Limited supplier options compared to open standards.

Choosing the Right Taper

Your choice depends on your application, machine capabilities, and budget:

- For General Machining:CAT and BT are cost-effective and reliable for most milling and drilling jobs.

- For High-Speed Machining:HSK is designed for precision and performance at high RPMs.

- For Multi-Tasking and Heavy Cutting:Capto delivers unmatched versatility and torque.

By understanding each system’s strengths and limitations, you can equip your machine for optimal performance and precision.

How Spindle Taper Types Apply to Leading CNC Machine Tool Brands

Choosing the correct spindle taper isn’t just about the theoretical benefits—it directly impacts how your specific machine tool performs. Here’s how the major taper types discussed in this blog are implemented in the most popular CNC machines on the market:

- Haas Automation: Haas vertical and horizontal machining centers almost universally use CAT tapers (most commonly CAT40 and CAT50). Their lathes and mills in North America are built around the robustness and availability of the CAT standard, making them highly compatible with standard toolrooms and job shops.

- Mazak: Mazak offers a wide variety of spindle tapers to suit application demands. Their VTC and INTEGREX series often use BT or HSK tapers, with multi-tasking machines frequently leveraging Capto systems for both turning and milling versatility. High-speed machining centers from Mazak regularly feature HSK tapers for optimal accuracy.

- DMG Mori: As a global giant, DMG Mori’s machining centers and mill-turn machines support BT, HSK, and Capto tapers. The NHX and CLX series commonly feature BT or HSK spindles, while CTX and NTX multi-tasking lathes utilize Capto interfaces for maximum flexibility on the shop floor.

- Okuma: Okuma’s vertical and horizontal machining centers often come with CAT, BT, or HSK spindles depending on model and customer preference. For instance, the MU and MB series support high-speed HSK applications, while the GENOS and MA series frequently use BT or CAT for robust everyday cutting.

- Makino: Precision-focused Makino machines, like the a51nx and D-Series, are designed for high-speed, tight-tolerance applications, making HSK their taper of choice. However, Makino offers BT and CAT as well to accommodate legacy tooling and versatile manufacturing needs.

- Matsuura: Their high-speed vertical and 5-axis machining centers (such as the MX and MAM series) typically use HSK tapers, prized for rigidity, repeatability, and speed. Some BT options exist to service global markets and compatibility with existing tool inventories.

- Hurco: Hurco’s popular VMX series utilizes CAT tapers, making them a staple for U.S. job shops. Select models support HSK for advanced precision and surface finish requirements.

- Doosan (DN Solutions): Doosan VMCs and HMCs are available with CAT or BT spindle options, with their high-speed and 5-axis lines transitioning toward HSK to keep pace with advanced manufacturing needs.

- Brother: Well-known for rapid drilling and tapping centers, Brother almost exclusively uses BT30 and BT40 spindles, providing fast tool changes and reliable performance in mass production and high-mix manufacturing.

- Kitamura: Kitamura’s vertical and horizontal machining centers are offered with BT and HSK tapers. The HX and Mycenter series are renowned for their tight tolerances and benefit from HSK tapers in high-speed, precision-driven applications.

- Hyundai WIA: BT and CAT are both common on Hyundai WIA’s machining centers, serving diverse industries. Their X-axis travel VMCs accommodate BT tooling, while large bridge mills might use CAT.

- Toyoda: Toyoda machining centers are widely configurable with BT, CAT, or HSK spindles, giving users the freedom to pick the interface that best matches their production goals and legacy tool crib investments.

- Grob: Grob’s universal machining centers, such as the G350 and G550 series, are noted for their use of HSK tool holders, enabling aggressive 5-axis work and superb finish quality across the automotive and aerospace sectors.

No matter which manufacturer’s machine you own—be it a Mazak INTEGREX with Capto, a Haas VF mill with CAT, or a Matsuura 5-axis with HSK—choosing the right taper and keeping it in peak condition is vital for optimal machine performance, uptime, and part quality.

Why Trust Motor City Spindle Repair with Your Spindle Taper Rebuilds?

Here’s what sets us apart:

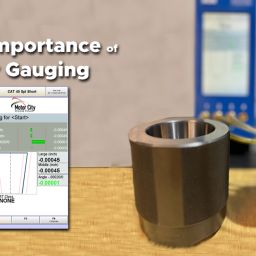

- Unmatched Expertise: Our team has hands-on experience with every major spindle taper system, ensuring repairs and rebuilds meet or exceed OEM specifications.

- Decades of Experience: With years of industry experience, we have successfully rebuilt spindles for thousands of customers across all major industries—including those running the brands listed above.

- Advanced Facilities: Motor City Spindle Repair uses state-of-the-art diagnostic, grinding, and balancing equipment to restore spindles to precise tolerances, maximizing tool life and machine uptime.

- Comprehensive Service: From emergency repairs and preventive maintenance to full overhauls, we handle everything in-house with fast turnaround times.

- Proven Results: Customer satisfaction is at the core of our business, reflected in our exceptional track record and repeat clientele.

- Nationwide Support: Serving customers across the United States, we offer quick response, detailed communication, and world-class service.

Whether you’re running high-speed HSK spindles in aerospace, robust CAT tapers in heavy industry, or modular Capto interfaces in advanced multi-tasking machines, Motor City Spindle Repair provides peace of mind and performance you can trust. Our experience spans the most respected brands—Haas, Mazak, DMG Mori, Okuma, Makino, Matsuura, Hurco, Doosan, Brother, Kitamura, Hyundai WIA, Toyoda, and Grob—ensuring your spindle, no matter the make, gets the attention it deserves.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE