Why is Vibration Analysis Important?

Vibration analysis is essential for CNC (Computer Numerical Control) machining centers because excessive vibration can significantly impact the accuracy and quality of the machined parts. CNC machining centers use high-speed cutting tools to produce precise and complex parts, and any vibration or chatter during the machining process can cause the tool to deviate from the intended path, resulting in inaccuracies and defects.

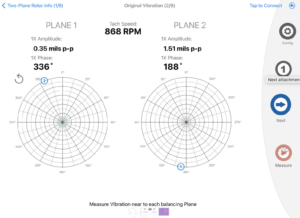

Vibration analysis helps identify and diagnose the root cause of any excessive vibration in the machine tool system. By analyzing the vibration patterns, frequency, and amplitude, the technician can determine the source of the problem, such as an unbalanced tool holder, worn bearings, loose fasteners, or a faulty spindle.

Addressing the vibration issues early on can prevent further damage to the machine, reduce the likelihood of tool breakage, and improve the overall quality and productivity of the machining process. Additionally, regular vibration analysis can be part of a preventive maintenance program to detect and fix potential problems before they become more significant issues.

Motor City now offers…

SPINDLE DYNAMICS STUDIO PACKAGES

ALL YOUR CNC SPINDLE TESTING NEEDS IN ONE PACKAGE

The SDS package by Motor City Spindle Repair is made by and for manufacturing and Spindle Repair Professionals. It allows them to test, diagnose, and balance any Spindle Machine.

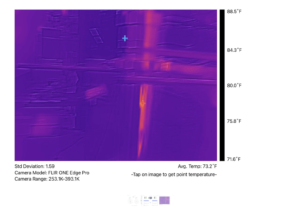

SDS relies on the IOS 17243-1.2 Standard to assess the severity of machine tool spindle vibrations, provide automated spindle fault condition, balance in 1 or 2 planes and even use the latest infrared camera technology to test bearing cooling integrity.

After tests are completed, automated reports are created which can then be printed, emailed, and stored locally or in cloud.

AVAILABLE TESTS:

SPINDLE VIBRATION TEST

SPINDLE TEST RUN LOGGER

VIBRATION ANALYSIS

BALANCE IN 1 AND 2 PLANES

SPINDLE THERMAL IMAGING

THE CNC SPINDLE REPAIR EXPERTS

Motor City Spindle Repair specializes in Spindle Repair in all areas, and we are able to provide quality services for below :

Horizontal Machining Centers Spindle Repair,

Vertical Machining Centers Spindle Repair,

Turning Centers Spindle Repair,

Grinding Machines Spindle Repair,

Precision Machine Tool Spindle Application Repair,

with Emergency Repair Lead Times,

We rebuild Belt Driven, Gear Driven, and Direct Driven spindles.

CONTACT US ANYTIME IF YOU’D LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

*Quotations are 100% free of charge

*All quotes are accompanied by a detailed failure analysis report

*We frequently repair spindles in 2-5 business days in emergency situations

*Normal time averages 1-3 weeks for standard repairs

*We keep precision bearings, seals, o-rings, encoders, and other commonly replaced spindle parts in stock and on hand

*Always available 24 hours a day and 7 days a week for emergency repair service

*We deliver the repaired product to you

*Our repairs are balanced, test ran, and certified with a full 1 Year Warranty

*We repair or build new depending on your needs

*Guaranteed cost savings

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE Have questions about ballscrews? Check out our BALL SCREW WEBSITE