Why Most CNC Spindle Repairs Fail (And How to Avoid Costly Mistakes)

When your CNC spindle fails, downtime costs pile up fast. Production stops, deadlines slip, and repair bills mount. The pressure to get back online quickly often leads manufacturers to choose the first available repair service—a decision that frequently backfires.

Common Failures in CNC Spindle Repair

Inadequate Diagnostic Capabilities

Many repair shops jump straight into disassembly without proper diagnostic testing. They rely on visual inspection alone, missing underlying issues that caused the initial failure. This approach treats symptoms rather than root causes.

Inexperienced technicians often lack the specialized equipment needed for comprehensive spindle analysis. They can’t measure critical parameters like dynamic balance, thermal characteristics, or bearing preload accurately. Without this data, they’re essentially guessing at solutions.

![]() Poor Quality Control and Testing

Poor Quality Control and Testing

Substandard repair companies skip crucial testing phases to reduce turnaround time. They may balance the spindle statically but ignore dynamic balancing requirements. This oversight leads to vibration problems, premature bearing failure, and poor surface finishes.

Temperature testing is another commonly skipped step. Spindles that haven’t been properly thermal-cycled often fail shortly after installation when they encounter normal operating conditions.

Inadequate Machining Capabilities

Spindle repair requires precision machining of critical components like bearing journals, shaft tapers, and housing surfaces. Many repair shops lack the sophisticated equipment needed for these operations.

They may outsource machining work to third parties, creating quality control gaps and extended lead times. Each handoff introduces potential for error and miscommunication about specifications.

Inexperienced Technicians

The most significant factor in repair failure is technician inexperience. Spindle repair demands deep understanding of bearing systems, thermal expansion, dynamic balancing, and precision measurement. This expertise only comes from years of hands-on work with various spindle

designs.

Inexperienced technicians make assembly errors, use incorrect bearing preloads, or fail to recognize signs of secondary damage. They may also lack familiarity with specific machine tool brands and their unique requirements.

Insufficient Warranty Coverage

Companies that lack confidence in their work offer limited warranties or exclude critical failure modes. This approach shifts risk back to the customer and signals potential quality issues.

Why Motor City Spindle Delivers Superior Results

Motor City Spindle has earned recognition as North America’s most trusted CNC spindle repair company through decades of specialized focus and continuous improvement. Their approach addresses every common failure point that plagues the industry.

Unmatched Technical Expertise

Motor City Spindle’s technicians average over 20 years of experience each. This deep expertise spans all types of spindles, from high-speed grinding applications to heavy-duty machining centers. Their team understands the subtle differences between spindle designs and how various operating conditions affect performance.

This experience level allows them to spot problems that newer technicians miss. They can predict failure patterns, identify root causes quickly, and implement solutions that prevent recurring issues.

Comprehensive In-House Capabilities

Unlike repair shops that outsource critical operations, Motor City Spindle maintains complete in-house control over the repair process. Their facility includes:

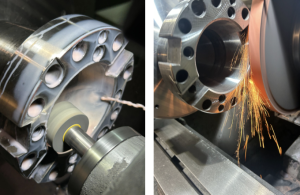

Advanced Machine Tool Shop: Precision machining capabilities for all spindle components, including worn housing repairs and bearing journal restoration.

Grinding Capabilities: Complete grinding services for spindle shaft tapers, bearing surfaces, and other critical dimensions that require superior surface finish and dimensional accuracy.

Dynamic Balancing Systems: State-of-the-art balancing equipment that ensures spindles meet or exceed OEM specifications for smooth operation at all speeds.

Trim Balancing: Fine-tuning capabilities that optimize balance for specific operating conditions and tool configurations.

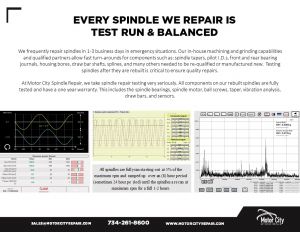

Rigorous Testing and Quality Assurance

Every spindle undergoes comprehensive testing before shipment. This includes:

- Complete dimensional verification

- Dynamic balance testing across the full speed range

- Thermal cycling to verify stability

- Vibration analysis under various load conditions

- Runout measurement at multiple locations

Full certification documentation accompanies each repaired spindle, providing complete traceability and performance verification.

Industry-Leading Warranty

Motor City Spindle backs their work with a full one-year in-service warranty. This comprehensive coverage demonstrates confidence in their repair quality and provides customers with genuine peace of mind.

The warranty covers not just parts and labor, but actual performance in production environments. This commitment reflects their understanding that spindle repair success is measured by long-term reliability, not just initial function.

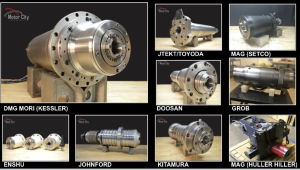

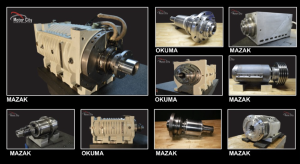

Extensive Brand Expertise

Motor City Spindle regularly services spindles from virtually every major machine tool manufacturer. Their extensive experience includes:

Machining Centers: DMG Mori, Mazak, OKK, Kitamura, Doosan, MAG, Fives, G&L, SNK, Fidia,Parpas,CMS

Turning Centers: Mazak, Okuma, MAG, Doosan, DMG Mori, Fuji

Grinding Applications: Setco, GMN, Kessler, Weiss, Omlat, UVA, Heald, Cincinnati

Specialized Machines: Ingersoll, SW, Alfing, Klingelnberg, Gleason, Liebherr, EMAG, Fuji

Bearing Systems: NSK and other premium bearing manufacturers

This brand diversity means Motor City Spindle technicians understand the specific requirements, common failure modes, and optimal repair procedures for each manufacturer’s designs.

Choosing the Right Repair Partner

When evaluating spindle repair companies, look beyond price and turnaround time. Consider these critical factors:

Technician Experience: Ask about average technician experience levels and training programs. Experienced technicians prevent problems that inexperienced ones create.

In-House Capabilities: Verify that critical operations like precision machining and dynamic balancing are performed in-house with proper equipment.

Testing Procedures: Request details about testing protocols and certification processes. Quality repair companies will gladly explain their procedures.

Warranty Terms: Examine warranty coverage carefully. Comprehensive warranties indicate confidence in repair quality.

Industry Reputation: Research the company’s track record with similar applications and spindle types.

Making the Smart Choice for Your Operation

Spindle repair isn’t just about fixing what’s broken—it’s about preventing future failures and optimizing performance.

Motor City Spindle’s combination of experienced technicians, comprehensive in-house capabilities, rigorous testing, and industry-leading warranty makes them the clear choice for manufacturers who can’t afford repair failures. Their expertise spans every major machine tool brand and application, ensuring your spindle receives the specialized attention it deserves.

Don’t let inexperienced repair companies turn your spindle problem into a recurring nightmare. Contact Motor City Spindle to discuss your specific requirements and experience the difference that true expertise makes.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE