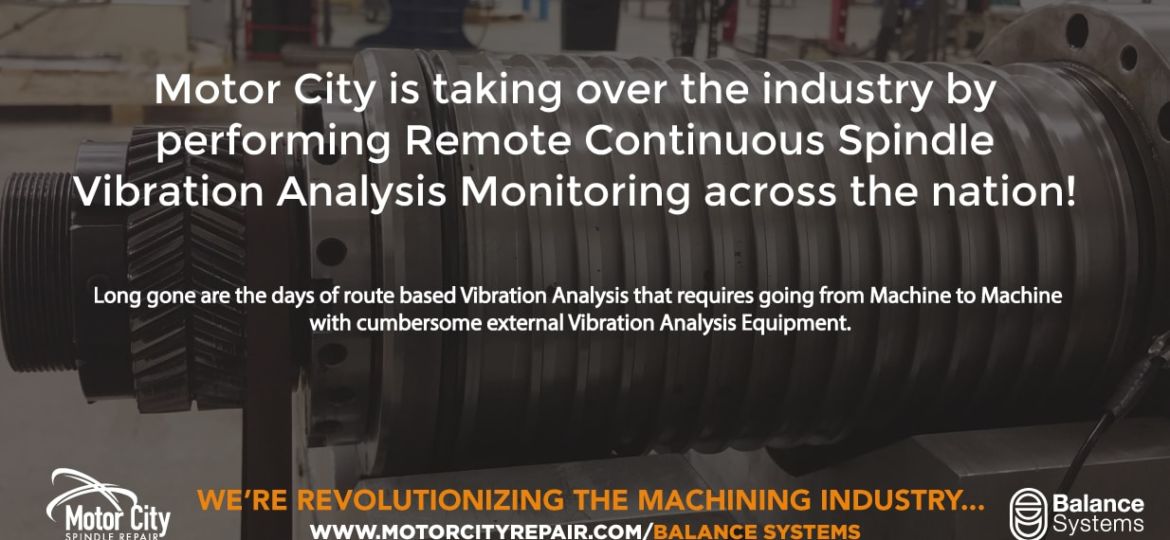

Motor City is taking over the industry by performing Remote Continuous Spindle Vibration Analysis Monitoring across the nation!

Motor City and Balance Systems signed a contract back in August of 2018 to sell their product exclusively in the entire USA.

This allows our customers to monitor the health of their Machining Center, Turning Center, Grinding and other Machine Tool Spindles in real time from anywhere.

Long gone are the days of route based Vibration Analysis that requires going from Machine to Machine with cumbersome external Vibration Analysis Equipment.

Please contact our staff to learn how The Motor City Spindle Repair Team can:

– Upgrade your Spindles / CNC Machines to Continuously Monitor your Spindles

– Full On-site Integration of this easy to use System

– Free on-site Demos

***Prices range from only $1500-3000.

***Balance Systems is a well know Vibration Analysis provider already sold on many new equipment by major Machine Tool OEMs.

Corporations already using Balance Systems:

Ford Motor Company

General Motors

FCA Fiat Chrysler Automobiles

ZF Group

Eaton

Daimler Trucks North America

FIND OUT HOW WE’RE REVOLUTIONIZING THE MACHINING INDUSTRY HERE…

WWW.MOTORCITYREPAIR.COM/BALANCE-SYSTEMS

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

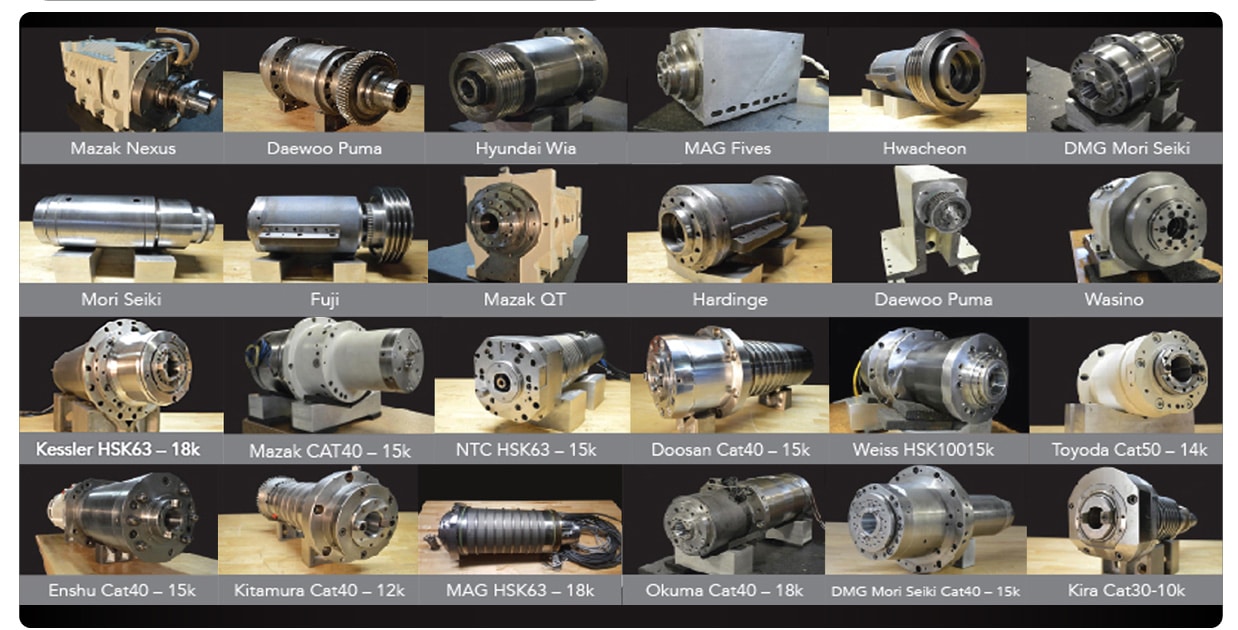

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair