MOTOR CITY SPINDLE OFFERS SUPPORT FOR THE FOLLOWING SERVICES:

• Spindle Bearings: NTN, SKF, FAG, Barden, GMN, Fafnior, Timken and all major Name Brands.

• Draw Bar Components

• Orings/Seals

• Motor Rewinds

• Spindle Taper Grinding

• Bearing Journal Rework

• Housing Bore Rework

• Spindle Upgrades

• Complete Spindle Repair Services

Please let us know if we can be of assistance with immediate pricing. Emergency Service Available at (734) 261-8600 or shelby@motorcityrepair.com

ANGULAR CONTACT BEARINGS

Angular contact ball bearings have raceways in the inner and outer rings that are displaced relative to each other in the direction of the bearing axis. This means that they are designed to accommodate combined loads (simultaneously acting radial and axial loads).

The axial load carrying capacity of angular contact ball bearings increases with increasing contact angle. The contact angle is defined as the angle between the line joining the points of contact of the ball and the raceways in the radial plane, along which the load is transmitted from one raceway to another, and a line perpendicular to the bearing axis.

ROLLER BEARINGS

Roller Bearings have outer and inner rings which contain bearing cage and rollers. The cage is also called separator or retainer that maintains spacing between the rollers and also holds the bearings together. A wide range of roller bearings are available each with distinct designs used in different applications. There are four major types of roller bearings:

Spherical roller bearings – They have two rings on the inner raceway that handle loads and misalignment concerns.

Cylindrical roller bearings – They handle low thrust and high radial loads at high speeds.

Needle roller bearings – They use long and thin cylindrical rollers for supporting radial loads.

Tapered roller bearings – They have tapered outer and inner rollers and raceways to accommodate the simultaneous thrust and radial loads.

Call us at (734) 261-8600 or email us at Sales@motorcityrepair.com to learn more.

157+ Years of Experience In Our Spindle Room Serving the Largest Corporations in the USA

Aerospace

Automotive

Agriculture

Machine Tool

and many others

24/7 Emergency Repair Service + We Deliver.

Industry’s Most Aggressive 1-3 weeks for standard repairs

We will get your machine running in no time.

Dedicated staff available 24/7 to assist you with emergency spindle repair services.

We offer door-to-door pickup and delivery on our emergency repair services.

We Repair Depending On Your Need.

Guaranteed Cost Savings as we have in-house machining and grinding capabilities

8 Full Time Technicians in our spindle room

Balanced, Test Run, and Certified with A Full 1 Year Warranty

Spindles are test run at maximum RPM, while performing vibration & temperature analysis.

Bearings are checked for velocity & displacement.

All electrical components are tested, repaired and replaced as needed.

Dynamic & Static Balancing of Spindles at maximum RPM.

Repair specialists for your Motorized or Belt Driven machines:

Horizontal Machining Centers

Vertical Machining Centers

Turning Centers

Grinding Machines

Any other machine tools

We offer the following spindle upgrades:

Air Purge

Ceramic Bearings

New Bearing Configuration

Encapsulate Motor Windings

Retrofit spindle shaft with removable drive keys

We specialize in Fanuc Servo Motor Repair, including:

i series

DiS series

ALPHA series

BETA Series

ROBODRILL series

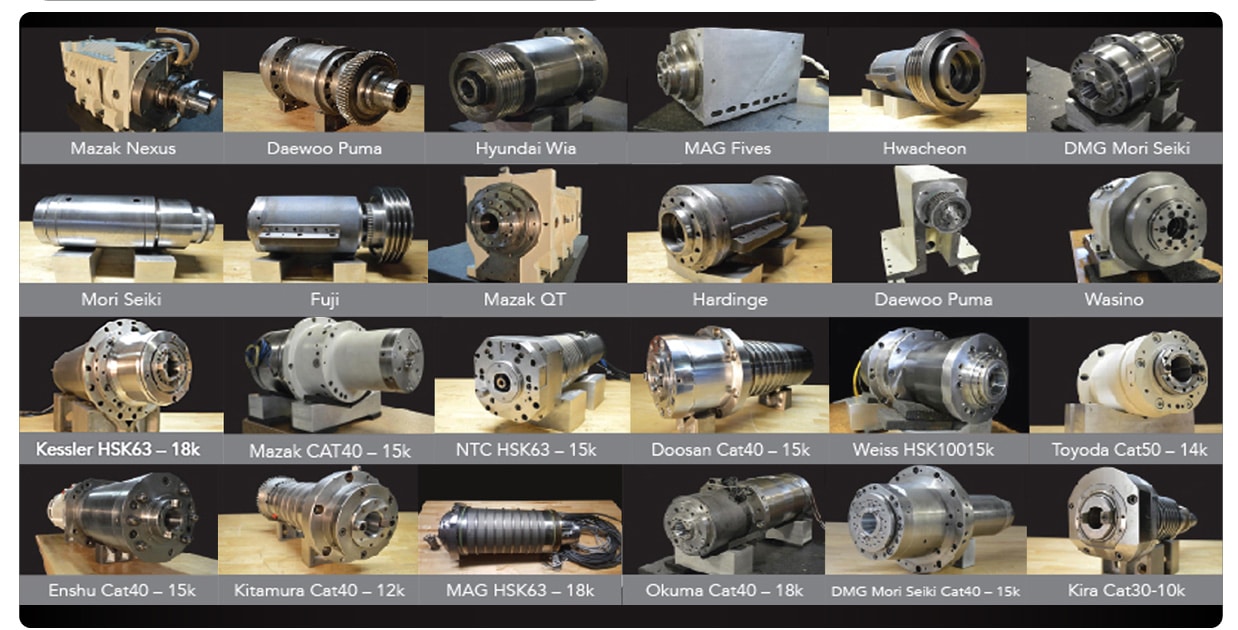

OEM Types we specialize in:

Bryant Spindle Repair

Dmg Mori Spindle Repair

Doosan Spindle Repair

Enshu Spindle Repair

Ex-Cell-O Spindle Repair

Fanuc Cnc Spindle Repair

Felsomat Spindle Repair

GMN Spindle Repair

Grob Systems Spindle Repair

Hardinge Spindle Repair

Heller Spindle Repair

Kessler Spindle Repair

Kitamura Spindle Repair

Mag Spindle Repair

Mazak Spindle Repair

Mitsubishi Spindle Repair

Mitsui Seiki Spindle Repair

Mori Seiki Spindle Repair

Niigata Spindle Repair

NTC Spindle Repair

Okamoto Spindle Repair

OKK Spindle Repair

Okuma Spindle Repair

Omlat Spindle Repair

Pope Spindle Repair

Setco Spindle Repair

SNK Spindle Repair

Weiss Spindle Repair