When a CNC spindle goes down, production stops. Every minute of downtime costs money. For years, the world’s largest CNC machine tool OEMs have told manufacturers that only they can repair their spindles, locking customers into outrageously expensive service programs.

doosan

In CNC machining, precision and rigidity are key. The connection between the machine spindle and tool holder directly affects performance, accuracy, and surface finish.

Boring mill machines are essential tools for industries that demand precision and efficiency when handling large-scale parts. From automotive and aerospace to heavy equipment manufacturing, these machines deliver accuracy and reliability for producing high-quality components.

Turning center CNC machines are essential for modern manufacturing, offering precision, efficiency, and adaptability in industries like automotive and aerospace. Brands like DMG Mori, Mazak, Okuma, and Doosan lead the way with innovative solutions.

What is IMTS? Exploring the International Manufacturing Technology Show In the world of manufacturing and industrial technology, few events hold…

Exploring the Pinnacle of Precision: The Most Popular CNC Machining Centers In the realm of manufacturing, precision is paramount. From…

with or without you referrals DO YOU WORK WITH IN THE CNC MACHINE TOOL INDUSTRY? If you are interested in…

MACHINE TOOL SHAFTS & CHROME Rebuilding CNC machine tool spindle shafts with hard chrome involves several steps. Here’s a general…

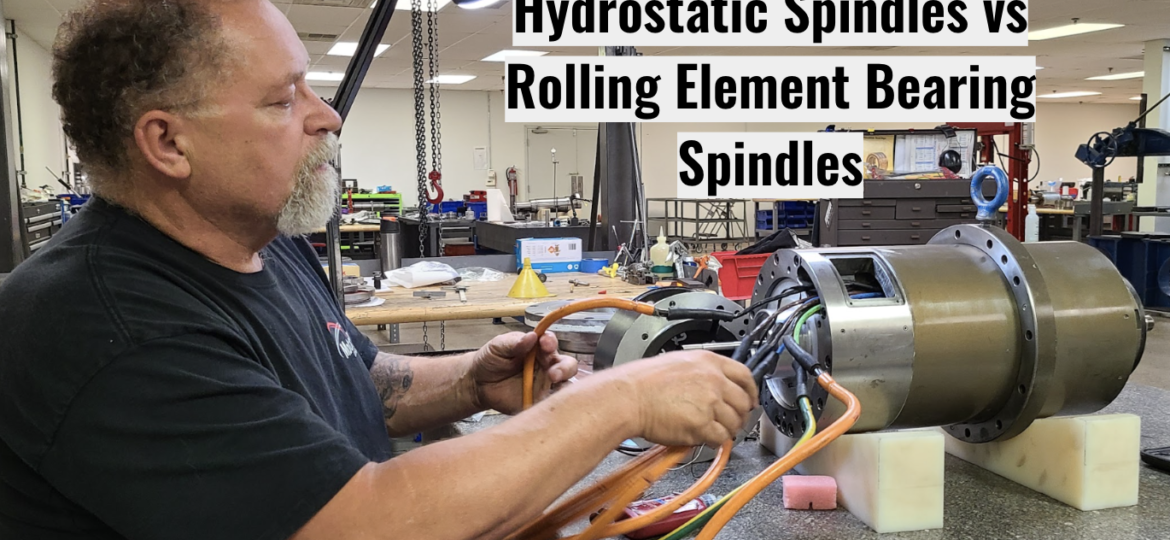

Hydrostatic Spindles vs Rolling Element Bearing Spindles Hydrostatic spindles and CNC machine tool spindles with rolling element bearings are two…

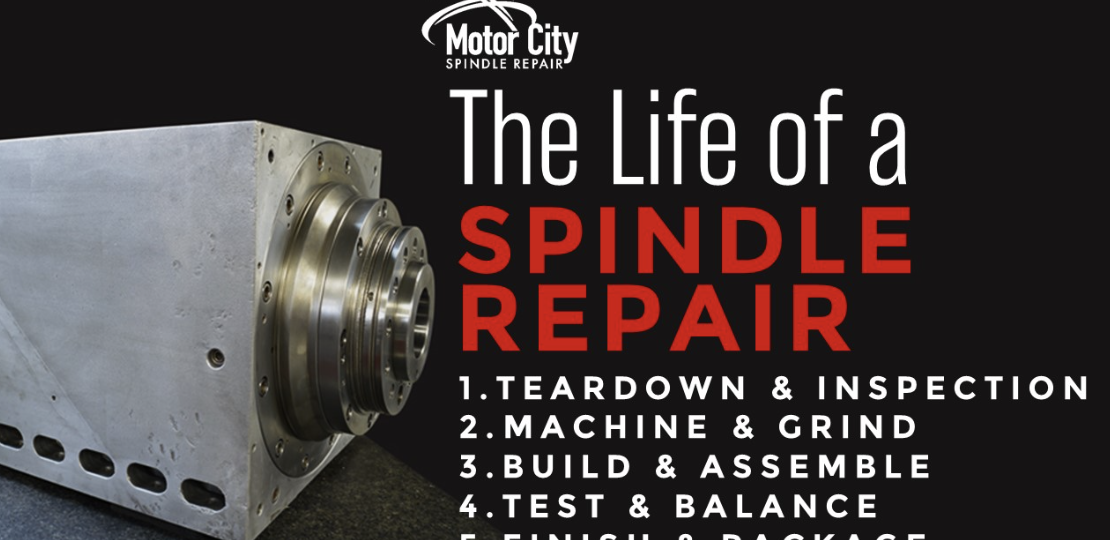

The Spindle repair process at motor city spindle: There are 5 basic steps to repairing a spindle. 1. Teardown &…