How Vibration Analysis Keeps CNC Spindles Running Smoothly

Why Spindle Vibration Tells the Whole Story

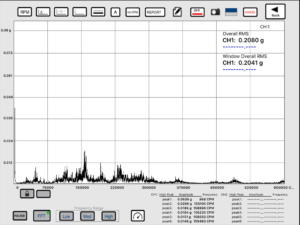

A spindle might look fine on the outside, spinning at thousands of RPM without a hitch. But beneath the surface, tiny imbalances, worn bearings, or slight misalignments can create vibrations that silently degrade part quality and shorten spindle life. By measuring these vibrations, shops can catch problems early—before they turn into expensive repairs or unexpected downtime.

WHY VIBRATION ANALYSIS IS IMPORTANT TO A CNC MACHINE

It is important to a CNC Machine because excessive vibration can lead to various problems such as reduced accuracy, poor surface finish, increased wear and tear on machine components, and even machine failure.

Motor City Spindle Repair: On-Floor Diagnostics That Work

At Motor City Spindle Repair, we bring vibration analysis directly to your shop floor. Our technicians use advanced tools to map your spindle’s vibration patterns, identify irregularities, and diagnose potential failures—all without sending your machine offsite. The result? You get accurate insights and actionable solutions while keeping production humming.

Empowering Shops with Spindle Dynamics Studio Packages

Some shops want to take preventative maintenance into their own hands. That’s why we created the Spindle Dynamics Studio Packages—wireless vibration analyzers designed for operators and maintenance teams. These packages let you track spindle health over time, schedule repairs proactively, and catch small issues before they become costly problems. It’s like having a personal spindle health dashboard, right on your shop floor.

The Benefits Speak for Themselves

-

Catch issues early: Spot minor problems before they lead to major failures.

-

Maintain part quality: Keep precision high and scrap low.

-

Save money: Reduce unplanned downtime and expensive emergency repairs.

-

Take control: Give your team the tools to monitor spindle health on their own schedule.

Conclusion

Vibration analysis isn’t just a maintenance tool—it’s a game-changer for CNC shops that value precision, efficiency, and reliability. Whether you bring Motor City technicians in for on-floor diagnostics or use a Spindle Dynamics Studio Package to monitor spindles yourself, staying ahead of spindle issues keeps your machines running—and your shop profitable.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE