what to look out for if your cnc maching is breaking down

Here are a few signs your unit may need to be repaired soon.

- If you’re noticing finishing issues on your machined parts, that can indicate wear on your spindle.

- If you notice, wear on the spindle mouth. You can check this by using a toolholder and bluing. You can also check the runout with T.I.R.

- Check for signs of damage and wear on the inside of the toolholder. Fretting on the inside is the most common sign of wear and indicates a spindle issue.

- Unusual Vibration means spindle damage. Typically, this indicates bad bearings, so check the lubrication.

- Unusual Noise coming from the spindle itself is a clear sign of spindle damage.

- An increased temperature means spindle damage. The spindle should run cool, so the spindle should not become extremely hot even during operation.

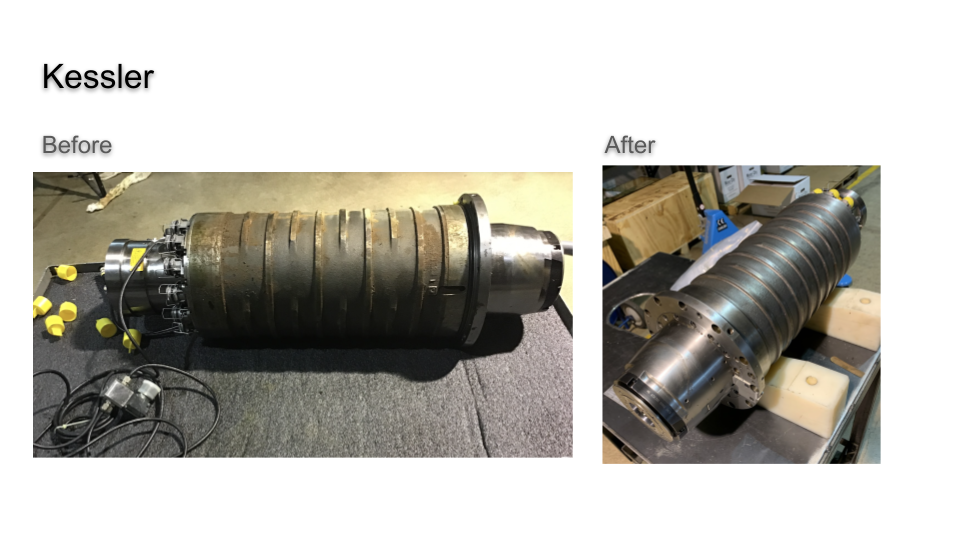

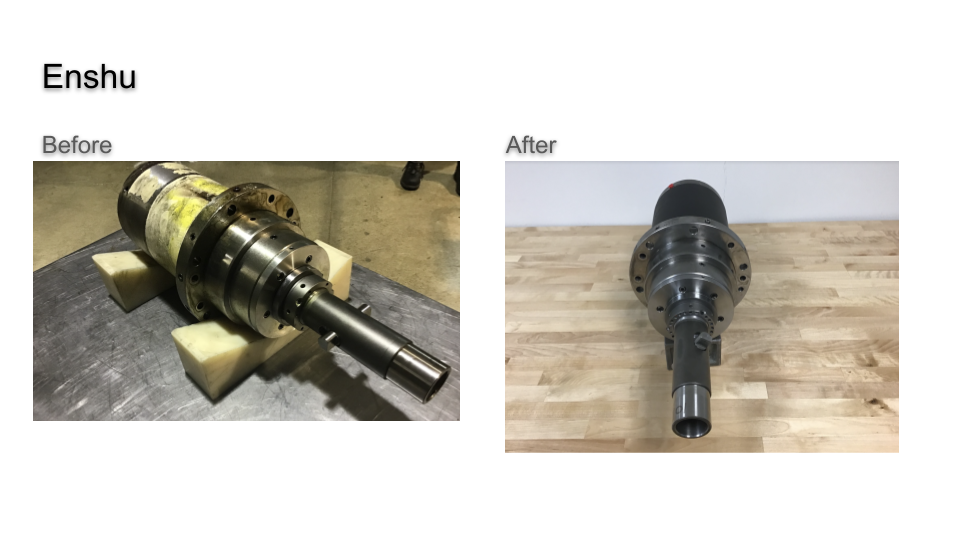

Here are a few examples of spindles we have repaired:

The quality of our work speaks for itself. Contact the team at Motor City Spindle Repair

Reach out to speak with one of the team members.

Click the link below to fill out our FREE spindler repair estimate form. https://bit.ly/3Q3qu1V