Preventive Maintenance for CNC Spindles: A Checklist for Reliability

The spindle is the heart of any CNC machine, directly affecting part quality, production speed, and operational costs. Unexpected spindle failures can halt production, causing costly downtime. The best way to avoid these failures is through proactive care. A consistent preventive maintenance routine ensures reliable spindle operation for years.

This guide provides a clear checklist for preventive maintenance, helping you catch potential issues early, optimize performance, and extend the lifespan of your spindle. From daily checks to in-depth periodic inspections, we’ve got you covered.

CNC Spindle Maintenance Checklist

A structured maintenance plan is key. This checklist breaks tasks into manageable daily, weekly, and monthly steps to ensure nothing is overlooked.

Daily Checks: Foundation for Reliability

Perform these quick checks at the start of each shift to prevent serious damage.

- Listen for Unusual Noises: Run the spindle and listen for grinding, whining, or rattling, which may signal bearing wear or contamination. A healthy spindle should operate quietly.

- Check Air Supply: For air-purged spindles, confirm proper air pressure and quality. Contaminated or moist air can cause internal corrosion and bearing failure.

- Inspect Tool Holder and Taper: Check for dirt, debris, or fretting corrosion (reddish-brown discoloration). A clean connection is vital for tool accuracy.

Weekly Maintenance: Deeper Inspections

Set aside time weekly for these detailed checks to maintain core spindle functions.

- Clean the Taper Thoroughly: Use a taper cleaning tool or lint-free cloth with solvent to ensure proper tool seating and reduce vibration.

- Test Drawbar Force: Use a force gauge to measure clamping force. Low force can cause tool slippage or damage and may indicate issues with springs or clamping mechanisms.

- Inspect Coolant and Lubrication Lines: Check hoses for leaks, cracks, or blockages. Proper coolant and lubrication prevent overheating and bearing damage.

Monthly and Quarterly Inspections: Proactive Analysis

These advanced tasks help predict and prevent failures.

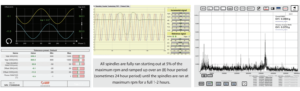

- Vibration Analysis: Use a vibration analyzer to monitor spindle housing at different speeds. Rising vibration levels signal bearing wear or misalignment.

- Temperature Monitoring: During long runs, check spindle housing temperature with an infrared thermometer. Excess heat can indicate lubrication or bearing issues.

- Inspect Bearings and Seals: Look for signs of grease leakage or rumbling sounds at low speeds, suggesting seal or bearing problems.

Common Mistakes to Avoid

Avoid these errors to prevent damage:

- Using Compressed Air on the Taper: This can push contaminants into the bearings, leading to failure.

- Ignoring Minor Changes: Small increases in vibration or temperature often indicate early problems.

- Improper Lubrication: Always use the manufacturer’s recommended lubricant type and quantity.

Benefits of Preventive Maintenance

Regular spindle care offers significant advantages:

- Longer Lifespan: Extend spindle life and maximize ROI.

- Reduced Downtime: Catch issues early to schedule repairs during planned shutdowns.

- Improved Part Quality: Minimize runout and vibration for better accuracy and surface finishes.

- Lower Repair Costs: Fixing minor issues early is cheaper than major repairs or replacements.

Why Choose Motor City Spindle?

Motor City Spindle leads the industry in expert spindle repair. Our skilled technicians provide precise diagnostics, expert repairs, and rigorous testing to restore spindles quickly and effectively. We prioritize fast turnaround without sacrificing quality, minimizing downtime and ensuring reliable performance.

What sets us apart is our dedication to customer satisfaction. We offer tailored solutions, clear communication, and ongoing support to meet your needs. By choosing Motor City Spindle, you ensure quality, reliability, and peace of mind.

Motor City Spindle Repair’s Spindle Dynamic Studio Package

To further enhance spindle longevity, Motor City Spindle Repair offers the innovative Spindle Dynamic Studio Package. This comprehensive service solution is designed to take your spindle maintenance to the next level. With advanced diagnostics, the package can detect early warning signs of potential issues before they become major problems. Precision balancing services ensure your spindle operates at peak performance, reducing wear and minimizing the risk of vibration-related failures. Additionally, the package includes predictive maintenance tools that monitor key operational metrics, providing actionable insights to prevent unplanned downtime.

By utilizing the Spindle Dynamic Studio Package, you gain a proactive edge in spindle care—extending service life, optimizing machine reliability, and protecting your bottom line.

Take Action for Spindle Reliability

Your CNC spindle’s reliability impacts your entire operation. Adopt this checklist to move from reactive repairs to proactive maintenance, protecting your investment and boosting efficiency.

Contact MCSR to start your daily, weekly, and monthly checks to reduce downtime, improve performance, and extend your spindle’s lifespan.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE