Silencing the Trouble: Diagnose Spindle Noise, Vibration & Overheating

When machines run smoothly, productivity thrives. But spindle noise, vibration, or overheating can disrupt operations, reduce precision, and lead to costly repairs. Diagnosing these issues early is critical—not just to maintain performance but to extend equipment life and avoid downtime.

This guide offers practical tips for identifying, diagnosing, and fixing spindle issues. Whether you’re a machine operator, technician, or business owner, you’ll find actionable steps to keep your machines running smoothly.

What Are Spindle Noise, Vibration, and Overheating?

Understanding these issues is the first step to solving them.

Spindle Noise

Unusual sounds like grinding, buzzing, or whining often mean worn bearings, poor lubrication, or imbalances. Ignoring these signs can worsen damage and lead to breakdowns.

Spindle Vibration

Excessive vibration shows up as shaking, uneven cuts, or abnormal patterns in parts. Common causes include misaligned components, tool imbalances, or wear over time. Left unchecked, vibration can damage other machine parts.

Overheating

Overheating can result from poor cooling, lack of lubrication, or overloading. It reduces spindle lifespan and machining accuracy. Signs include burning smells, heat from the housing, or discoloration.

These issues often start small but can escalate into serious problems. Early detection is key.

Warning Signs of Spindle Problems

Spotting these symptoms early can save you time and money.

Noise Indicators

- Grinding sounds from worn bearings or poor lubrication.

- Buzzing or whining from tool imbalances.

- Loud bumps or clicks, signaling loose parts or damage.

Vibration Indicators

- Visible shaking during operation.

- Poor-quality cuts or inconsistent finishes.

- Abnormal noises at high speeds.

Overheating Indicators

- Heat from the spindle housing.

- Burning smells or scorched materials.

- Discoloration or warping from heat buildup.

Recognizing these signs early lets you act before problems grow.

Common Causes of Spindle Issues![]()

Noise Causes

- Worn or poorly lubricated bearings causing friction.

- Tool imbalances or incorrect setups leading to buzzing or whining.

Vibration Causes

- Misaligned components disrupting smooth movement.

- Incompatible spindle speeds and tools creating vibration.

Overheating Causes

- Inefficient coolant systems causing heat buildup.

- Prolonged high-speed operations without proper cooling.

Addressing these root causes avoids trial-and-error fixes and resolves issues faster.

Tools for Diagnosing Spindle Problems

Using the right tools simplifies diagnostics:

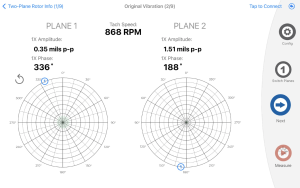

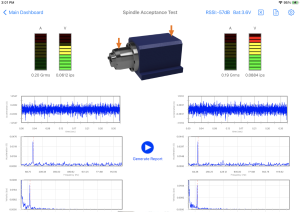

- Vibration meters: Identify alignment or balance issues.

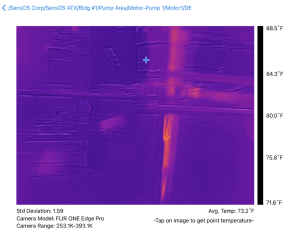

- Thermal imaging cameras: Detect hot spots around the spindle.

- Sound monitoring devices: Pinpoint internal problems like bearing wear.

Even affordable tools can provide valuable insights, while advanced systems offer real-time monitoring.

How to Diagnose Spindle Issues

Follow these steps when you notice warning signs:

- Observe and Document: Monitor performance, listen for unusual sounds, and log observations.

- Use Diagnostic Tools: Combine readings from vibration sensors, thermometers, and sound monitors.

- Inspect Bearings and Alignment: Check for wear, loose parts, or misalignments inside the spindle housing.

- Check Cooling and Lubrication Systems: Look for coolant blockages or degraded lubricant.

- Analyze Speeds and Loads: Ensure spindle speeds align with tool requirements to prevent issues.

Preventing Spindle Problems

After resolving issues, take these steps to avoid future problems:

Routine Maintenance

Regular checks on bearings, lubrication, and cooling systems catch small issues before they worsen.

Monitoring Systems

Real-time monitoring tools track temperature, vibration, and noise, alerting you to problems early.

WHY TRUST MOTOR CITY SPINDLE REPAIR?

When it comes to resolving spindle issues, Motor City Spindle Repair stands out as an industry leader. With years of hands-on experience and a team of skilled technicians, we have successfully diagnosed, repaired, and rebuilt thousands of spindles for businesses across the country. Our facility is equipped with advanced diagnostic and repair tools, ensuring precision and reliability for every repair.

We pride ourselves on transparent communication, fast turnaround times, and a commitment to total customer satisfaction.

Don’t wait for a breakdown—contact the CNC spindle repair experts with over 200+ years combined experience rebuilding spindles. A little care today can save you major downtime tomorrow.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE