CNC spindle bearing failure leads to downtime and scrap. Learn the most common causes, early warning signs, and how maintenance managers can prevent premature spindle failure.

Spindle Bearings

How Upgrading Bearings and Components Can Extend Spindle Life In manufacturing, the spindles performance directly impacts your production quality, efficiency,…

In the high-precision world of CNC machining, spindle bearings are the unsung heroes behind every smooth cut and perfect finish. These bearings are critical components of machine tool spindles, influencing not just spindle speed and rigidity, but also vibration,

Agriculture has witnessed a revolutionary transformation with the advent of advanced technology, enabling farmers and agribusinesses to enhance productivity, efficiency, and sustainability. Among these technological innovations, CNC (Computer Numerical Control) sp

Unveiling Precision: Exploring Various CNC Manufacturing Operations In the realm of modern manufacturing, Computer Numerical Control (CNC) machining stands as…

PREVENTATIVE MAINTENANCE Implementing a preventative maintenance program for your CNC machine tool machining facility is essential to ensure optimal performance,…

CERAMIC vs STEEL SPINDLE BEARINGS Why use Ceramic Bearings? Ceramic bearings are often used in CNC machine tool spindles because…

Different Grinding machines Before we look at the different types of CNC grinding machines, we first must understand what a…

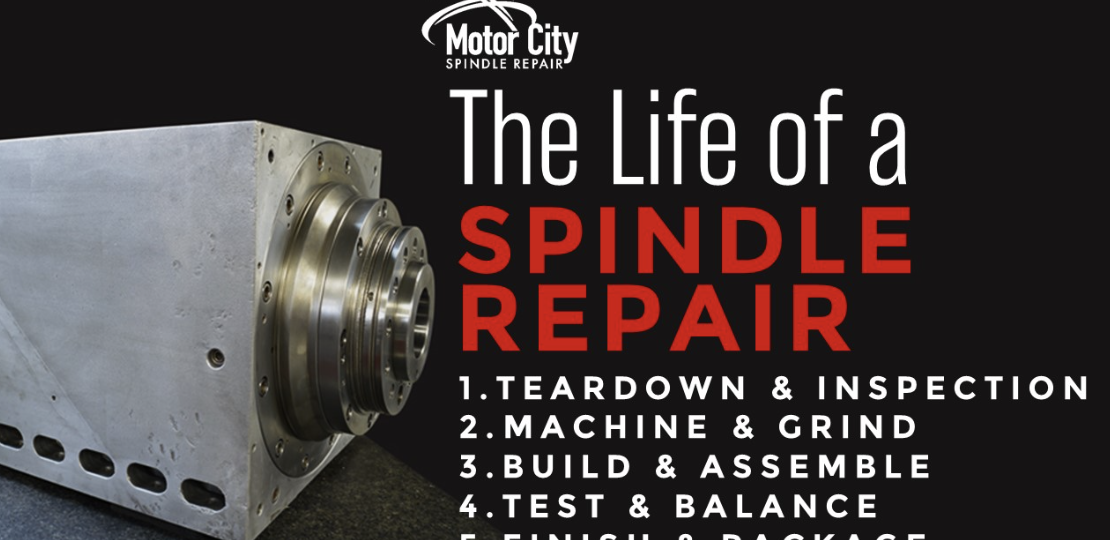

The Spindle repair process at motor city spindle: There are 5 basic steps to repairing a spindle. 1. Teardown &…

VISIT MOTOR CITY SPINDLE REPAIR AT IMTS 2022! After a long, three year wait, the International Manufacturing Technology Show is…