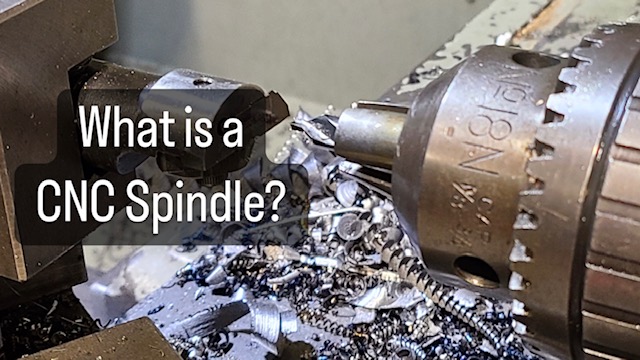

What is a cnc spindle?

A spindle is the heart and soul of any machine tool. CNC spindle often refers to the shaft at the center of the rotating axis of the machine tool. It rotates on an axis that receives input from the CNC controller. The form of the spindle determines the overall speed and cutting force of the machine tool. A machine can have multiple spindles or just one. If it only has one, that spindles is called the ‘main spindle’. There are also different spindle types for different industries. Some of these can include milling spindles, electric spindles, grinding spindles, high-speed spindles, lathe spindles, etc.

What is the purpose of the spindle?

Machines with spindles are typically used for manufacturing different CNC pieces; however, they can also be found in industries like woodworking, metalworking, and electrical component creations. The spindles main job is to rotate the axis or tool.

What are the main causes of spindle failure?

The 2 major causes: contamination and crashes.

Contamination: There are two forms of contamination: Chip or coolant ingression.

-Coolant ingression can get inside of a spindle motor and short out the windings or wash out the lubrication in the bearings. Both will lead to premature failures.

-Chip ingression mostly occurs when the metal chips from the machining process get inside of the bearings. Again, this causes premature failure.

But what leads to those events?

Design flaws in the spindle from the OEM or units being improperly assembled, tested and, in some cases, misused.

Crashes: Crashes normally occur because of operator or programming errors. Typically, it happens when the spindle is driven into the worktable or components that surround it. Damage to the shaft taper and spindle bearings will result. Additional Imperfections to the spindle bearing components will cause problems like vibration, excessive generation of heat, runout, etc. which all will lead to premature failures or immediate failures.

THE CNC SPINDLE EXPERTS-

MOTOR CITY SPINDLE REPAIR

Motor City Spindle Repair specializes in Spindle Repair in all areas, and we are able to provide quality services for below :

Horizontal Machining Centers Spindle Repair,

Vertical Machining Centers Spindle Repair,

Turning Centers Spindle Repair,

Grinding Machines Spindle Repair,

Precision Machine Tool Spindle Application Repair,

with Emergency Repair Lead Times,

We rebuild Belt Driven, Gear Driven, and Direct Driven spindles.

Check out our most recent blog to see where the Motor City Spindle team will be next! – https://motorcityrepair.com/mcsr-at-advanced-manufacturing-expo/

If you need a FREE ESTIMATE on a CNC spindle repair click here!

Interested in ball screw repair/remanufacturing services? Let’s click HERE!