Top CNC Machines Dominating Transmission Manufacturing

American transmission plants rely on specific machine tools that have proven their worth through years of continuous operation. These machines must handle complex geometries, maintain tight tolerances, and integrate seamlessly into high-volume production lines. The following ten CNC machines represent the industry’s top choices for transmission manufacturing, each offering unique capabilities that make them indispensable in modern automotive production.

Why Transmission Manufacturing Requires Specialized CNC Equipment

These requirements drive transmission manufacturers to invest in specialized CNC equipment. Unlike general-purpose machine tools, transmission-focused CNC machines offer features like advanced gear cutting capabilities, thermal stability systems, and multi-axis configurations that enable complete part processing in single setups.

The investment in premium CNC equipment pays dividends through reduced scrap rates, improved cycle times, and enhanced part quality. Leading transmission manufacturers understand that machine tool selection directly impacts their ability to meet automotive industry quality standards while maintaining competitive production costs.

Gleason: The Gear Manufacturing Specialist

The company’s advanced software packages enable the production of complex gear geometries, including bevel and hypoid gears that require precise tooth contact patterns. Gleason’s machines incorporate sophisticated control systems that automatically adjust cutting parameters based on material properties and desired surface finishes.

Transmission manufacturers particularly value Gleason’s ability to handle both rough and finish gear cutting operations. Their machines can process gears from initial roughing through final grinding, ensuring consistent quality throughout the manufacturing process. The integration of multiple operations in Gleason’s equipment reduces handling time and minimizes opportunities for dimensional variation.

DMG Mori: Horizontal Machining Center Excellence

The key advantage of DMG Mori’s horizontal configuration lies in its ability to access multiple part surfaces without repositioning. Large transmission housings can be completely machined in a single setup, eliminating the dimensional variations that often result from part transfers between machines.

Speed and productivity define DMG Mori’s approach to transmission manufacturing. Their machines feature rapid tool changers that minimize non-cutting time, while multi-axis capabilities enable complex contour machining operations. The robust construction of these machines ensures dimensional stability even under heavy cutting loads, making them ideal for high-volume transmission production.

Mazak: Multi-Process Manufacturing Solutions

The integration of multiple manufacturing processes eliminates the need for part transfers between different machines. Transmission shafts that previously required separate turning and milling operations can now be completed in one setup. This approach not only reduces manufacturing time but also improves dimensional accuracy by eliminating cumulative tolerances from multiple setups.

Mazak’s technology particularly excels in spline manufacturing, where precise tooth geometry must be maintained relative to shaft features. The ability to turn shaft journals and cut splines in the same setup ensures optimal part concentricity and dimensional relationships.

MAG: Powertrain-Focused Engineering

The rigid construction of MAG machines enables aggressive cutting parameters that result in high chip-removal rates. This capability is particularly valuable in transmission manufacturing, where production volumes demand efficient material removal while maintaining dimensional accuracy.

MAG’s focus on line integration sets them apart from general-purpose machine tool manufacturers. Their machines are designed to work seamlessly with automated material handling systems, enabling lights-out manufacturing operations that maximize equipment utilization while minimizing labor costs.

Okuma: Thermal Stability and Precision Turning

Thermal stability represents Okuma’s primary technological advantage. Their machines incorporate advanced thermal compensation systems that maintain dimensional accuracy even as ambient temperatures fluctuate. This capability is crucial in transmission manufacturing, where shaft dimensions must remain within extremely tight tolerances.

The intelligent control systems in Okuma machines continuously monitor cutting conditions and automatically adjust parameters to maintain optimal performance. This technology reduces scrap rates while ensuring consistent part quality throughout extended production runs.

Kapp Niles: Gear Grinding Excellence

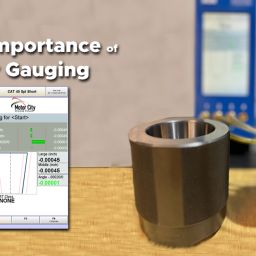

Kapp Niles machines represent the pinnacle of gear finishing technology. Their gear grinding machines are used throughout the transmission industry to achieve the surface finishes and dimensional accuracy required for quiet, efficient operation.

The precision achievable with Kapp Niles equipment is remarkable. These machines can achieve runout tolerances measured in micrometers while producing surface finishes that eliminate gear noise and maximize efficiency. Such precision is essential for modern transmissions, where customer expectations for refinement continue to increase.

Kapp Niles technology particularly excels in processing hardened gears. After heat treatment, gear teeth often require correction grinding to achieve final dimensions. The company’s machines can remove minimal material while achieving exceptional accuracy, preserving the metallurgical benefits of heat treatment.

Liebherr: Modular High-Speed Production

The modular design of Liebherr machines allows manufacturers to configure equipment specifically for their production requirements. Standard modules can be combined to create custom solutions that optimize throughput while maintaining quality standards.

High-speed operation defines Liebherr’s approach to gear manufacturing. Their machines can achieve cutting speeds that significantly reduce cycle times without compromising accuracy. This capability is particularly valuable in high-volume transmission production, where cycle time reductions directly impact manufacturing costs.

Grob: Versatile Aluminum Transmission Processing

The rigid table design of Grob machines provides exceptional stability during heavy cutting operations. Aluminum transmission cases often require substantial material removal to create internal passages and mounting surfaces. Grob’s machines can handle these operations while maintaining dimensional accuracy across large casting surfaces.

Tool flexibility represents another key advantage of Grob equipment. Their machines can accommodate a wide range of cutting tools, enabling complete housing machining in minimal setups. This capability reduces both cycle time and the potential for dimensional variation between operations.

Doosan: Cost-Effective Multi-Axis Solutions

The cost-effectiveness of Doosan equipment makes it particularly attractive for transmission manufacturers operating under tight budget constraints. Despite their competitive pricing, these machines deliver the accuracy and reliability required for automotive production.

High uptime percentages characterize Doosan machine performance. Their robust construction and reliable control systems minimize unexpected downtime, ensuring consistent production flow in demanding transmission manufacturing environments.

EMAG: Compact Vertical Processing

The vertical configuration of EMAG machines offers several advantages for transmission component processing. Parts can be loaded and unloaded without interrupting spindle operation, while the vertical orientation naturally evacuates chips and coolant. This design contributes to improved cycle times and enhanced part quality.

EMAG’s specialization in shaft and clutch hub operations has made them a preferred supplier for transmission manufacturers. Their machines are specifically configured for these applications, incorporating features that optimize performance for transmission-specific component

Motor City Spindle Repair is an excellent choice for rebuilding CNC machine tools used in transmission plants due to their extensive expertise and commitment to quality.

With years of experience in spindle repair and rebuilding, they understand the precise requirements of CNC machinery and how critical it is to maintain peak performance for production efficiency.

Their team utilizes state-of-the-art technology and high-quality components to restore equipment to like-new condition, ensuring reliability and longevity.

Additionally, Motor City Spindle offers rapid turnaround times, minimizing downtime and keeping transmission plants running smoothly. Their dedication to customer service and comprehensive support sets them apart as a trusted partner for CNC machine tool maintenance and repair.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE