Top 4 Boring Mill Machines Every Manufacturer Should Know

Boring mill machines are essential tools for industries that demand precision and efficiency when handling large-scale parts. From automotive and aerospace to heavy equipment manufacturing, these machines deliver accuracy and reliability for producing high-quality components.

This blog highlights the top four boring mill machines known for their innovation and performance. You’ll also learn the importance of maintaining these machines and how a professional CNC spindle repair partner, like Motor City Spindle Repair, can keep them in top condition for maximum efficiency.

What Are Boring Mill Machines?

-

- Horizontal boring mills: Ideal for machining long, heavy parts like engine blocks or gearboxes.

- Vertical boring mills: Designed for taller components like turbines, perfect for large cylindrical parts.

Modern boring mills, equipped with advanced CNC capabilities, offer greater accuracy and quicker turnaround times for complex tasks.

The Top 4 Boring Mill Machines![]()

Not all boring mills are created equal. These four machines stand out for their reliability, durability, and innovation:

1. Union Horizontal Boring Mills

Union’s horizontal boring mills are known for their robust construction and consistent performance under heavy workloads.

Key features:

- Durable design for long-term use.

- Precision machining of large, heavy parts.

- Customizable configurations for specialized tasks.

Where it excels: Shipbuilding, automotive, and heavy machinery manufacturing industries rely on Union’s machines for their durability and versatility.

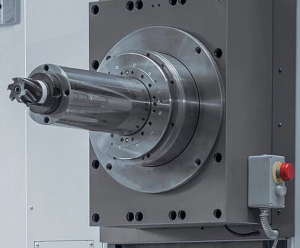

2. Giddings & Lewis Vertical Milling Machines![]()

Giddings & Lewis produces high-quality vertical boring machines, designed for heavy-duty applications with advanced CNC functionality.

Key features:

- Handles large, heavy parts with precision.

- High-performance spindle technologies.

- Multi-tasking options for diverse applications.

Where it excels: Power generation industries, where complex equipment like turbines demand precise machining.

3. Toshiba Horizontal Boring Machines![]()

Toshiba’s horizontal boring machines prioritize innovation, automation, and energy efficiency, making them highly effective for modern manufacturing.

Key features:

- Automated processes for enhanced productivity.

- Energy-efficient design for reduced costs.

- Excellent thermal stability for consistent accuracy.

Where it excels: Aerospace and precision engineering industries, where high-volume jobs require top-tier performance and accuracy.

4. Doosan CNC Boring Mills

Doosan is known for reliable and user-friendly CNC boring mills, designed for efficient small-to-medium batch production without sacrificing precision.

Key features:

- Intuitive CNC programming for ease of use.

- High-speed machining for quality and efficiency.

- Compact designs to save factory floor space.

Where it excels: General engineering and tool-making industries, where flexibility and reliability are critical for smooth operations.

Why Proper CNC Maintenance Is Crucial

Benefits of regular maintenance:

- Extends machine lifespan.

- Prevents unplanned downtime and missed deadlines.

- Maintains machining quality and consistency.

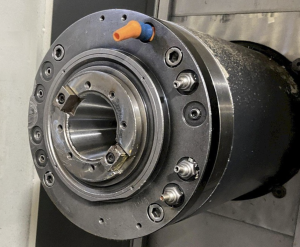

CNC spindles are particularly prone to wear, with issues like bearing damage or poor lubrication escalating into costly repairs if not addressed promptly.

Why Choose Motor City Spindle Repair?

Motor City Spindle Repair specializes in precision spindle repair, helping manufacturers keep their boring mills in top condition.

What sets us apart:

- Expert diagnostics to identify and fix issues quickly.

- Fast turnaround times for minimal downtime.

- Cost-effective repairs with a focus on quality and longevity.

Motor City Spindle Repair not only fixes problems but optimizes machine performance, helping manufacturers achieve better efficiency and productivity.

Conclusion

Boring mills are critical for precision manufacturing, enabling industries to produce large, complex components with accuracy. Whether it’s Union’s robust horizontal mills or Toshiba’s energy-efficient designs, each of the top four boring mills offers unique advantages tailored to industry needs.

Even the best machines require maintenance to stay in peak condition. Partnering with a trusted service provider like Motor City Spindle Repair ensures your boring mills remain efficient and reliable for years to come.

Don’t let downtime hurt your operations—contact Motor City Spindle Repair today to keep your machines running smoothly and optimize your manufacturing process.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE