Top Turning Center CNC Machines

Turning center CNC machines are essential for modern manufacturing, offering precision, efficiency, and adaptability in industries like automotive and aerospace. Brands like DMG Mori, Mazak, Okuma, and Doosan lead the way with innovative solutions.

Below, we’ll highlight what sets these turning centers apart, focusing on their features, technologies, and benefits.

1. DMG Mori – Precision Engineering at Its Best

DMG Mori combines German and Japanese engineering to deliver turning centers that prioritize precision, speed, and reliability.

Key Features

- Integrated Milling and Turning

The NTX Series reduces setup time and increases accuracy by combining milling and turning.

- Automation Options

Robotic arms and pallet changers boost efficiency.

- CELOS Interface

A touch-screen system simplifies setup and operation.

Applications

Ideal for industries like medical and automotive, capable of handling complex geometries and hard metals like titanium.

Why DMG Mori?

Combines precision and reliability for accurate, high-performance manufacturing.

2. Mazak – Multi-Tasking Redefined

Mazak’s INTEGREX Series combines machining processes for maximum efficiency.

Key Features

- SYNCHRO-MILL Technology

Simultaneous machining on multiple axes cuts downtime.

- SMOOTH TECHNOLOGY

Real-time monitoring and adaptive cutting improve productivity.

- Hybrid Solutions

Some models combine machining with additive manufacturing.

Applications

Excels in industries like aerospace, where complex profiles and exotic materials are common.

Why Mazak?

Reduces cycle times while increasing flexibility and output.

3. Okuma – Built for Reliability

Okuma’s durable CNC machines are designed for continuous production.

Key Features

- Thermo-Friendly Concept

Reduces heat expansion for consistent precision during long runs.

- OSP Control System

Advanced error correction for greater efficiency.

- Turn-Cut Technology

Combines turning and milling with minimal setup.

Applications

Popular in oil and gas sectors, where reliability and precision are critical.

Why Okuma?

Built for consistent performance under demanding conditions.

4. Doosan – Power and Affordability

Doosan offers high-performance turning centers at competitive prices, perfect for small-to-medium businesses.

Key Features

- High Torque Spindle Motors

Models like the PUMA GT Series excel at cutting hard materials.

- Box Guideways

Stability and reduced vibration ensure smooth finishes.

- Automation Options

Robotic integration improves productivity.

Applications

Widely used in automotive, power generation, and consumer electronics for high-volume production.

Why Doosan?

Affordable and reliable, balancing cost and performance for growing businesses.

Impact on Manufacturing

Turning center CNC machines excel at producing cylindrical parts like shafts and pipes. They help manufacturers:

- Achieve High Precision – Tight tolerances improve quality.

- Increase Output – Automation enables faster production.

- Reduce Waste – Accuracy minimizes material loss.

These machines meet demands for efficiency and quality across industries.

Choosing the Right Machine

- DMG Mori: Precision and advanced automation.

- Mazak: Multitasking and complex applications.

- Okuma: Durability for heavy-duty tasks.

- Doosan: Cost-effective, high-performance solutions.

Choose the right machine to maximize efficiency, minimize costs, and ensure top-tier output.

Final Thoughts

Selecting the right CNC turning center is a critical investment. From DMG Mori’s precision to Doosan’s affordability, today’s top brands offer solutions to elevate your manufacturing capabilities. Explore their features to find the best fit for your needs.

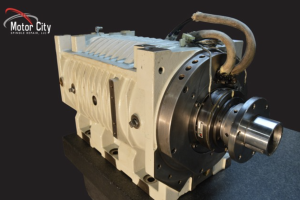

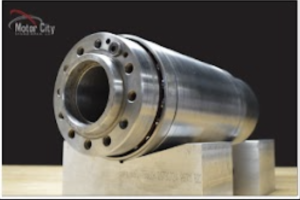

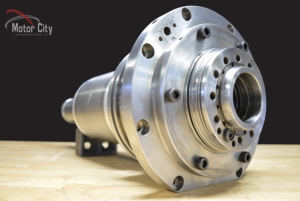

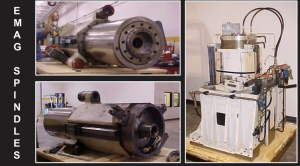

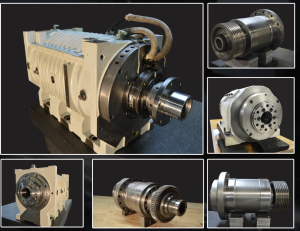

Why Trust Motor City Spindle Repair With Your CNC Turning Center Spindles

When uptime matters, choosing the right spindle repair partner is essential. Motor City Spindle Repair specializes in servicing and rebuilding turning center spindles from top brands like DMG Mori, Mazak, Okuma, and Doosan. By using advanced diagnostic tools and quality replacement parts, our experienced technicians restore your spindles to peak performance quickly.

Motor City Spindle Repair prioritizes transparency, detailed failure analysis, and thorough testing, ensuring minimal downtime and reliable repairs. With a strong focus on customer satisfaction and quality, we help extend the life of your spindles and safeguard productivity.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE